Access ControlAccess Control is a security measure put in place to ensure the correct people gain access to locations with selective permission based restrictions. If you’ve ever used a key card to pass through a gate, you’ve used access control.

Security Installers often design and install this equipment which can be controlled on site or off site through a network.

Asset ManagementPhysical Asset Management is the process engineers and technicians use to ensure their client's assets are working to peak performance. Effective Asset Management avoids unexpected breakdowns leading to downtime.

Today, it's vital that the office and the team on site can share information in real-time. That's why Field Service businesses use

Asset Management Software to see the service history and parts availability for their clients.

Attach RateThe percentage or ratio of service contracts sold at the point of a transaction is referred to as the Attach Rate. These present themselves as the best opportunities for business to sell value added services.

The customer or client is already engaging with your business and is likely to be receptive to additional services such as ongoing service contracts.

When you buy a coffee at your favourite stop, the frequency you buy an additional croissant or bacon roll would be the Attach Rate ratio.

Learn More.

Automated Dispatch SoftwareAutomated Dispatch Software automates the movement of people, goods and services. It allows a Field Service business to set up conditions to activate the dispatch to their clients. For example, this could be time based for regularly used products or inspections or be initiated on certain stock levels.

Automating this process removes the risk of human error such as forgetting an appointment or the restock of an item. Automated Dispatch software also reduces the amount of paper based admin, which is difficult to manage and leaves your business open to risks such as misplacing paperwork.

Automated Service RemindersThese are Automated Communications to your client reminding them of an upcoming service or inspection. This is a great way to ensure you never miss a service and your client's assets remain in top condition.

It's an added value service offering that Field Service Businesses can offer their clients.

With Klipboard you can set up

Automated Service Reminders and make them personalised for each client. They run in the background so you don't need to remember to send emails or SMS messages out to the client.

Bill of MaterialsIn engineering, this is sometimes referred to as the Engineering Bill of materials (EBOM), they are used when designing a product or ahead of a repair procedure. These lists contain a full report of the parts and assemblies required to complete the repair or build. The BoM or EBOM normally includes:

- Level of importance of the part

- Part number

- Part number

- Part name

- Description

- Phase of life cycle used

- Quantity

- Unit of measure. (millimetres, inches, meters, ounces)

BioMedical EquipmentBiomedical Equipment primarily is patient healthcare or laboratory equipment used to diagnose and treat patients. Mostly used in Operating theatres, Hospitals, and A&E wards. Field Service Engineers who service Biomedical Equipment have to ensure the equipment is kept in peak condition so their healthcare clients can offer their patients first rate care and treatment.

These sophisticated pieces of equipment often require regular servicing and rebalancing. Many Field Service businesses who specialise in

Medical and Healthcare will ensure their client's assets are put on a Planned Preventative Maintenance Structure (PPM), this ensures that the equipment is maintained at a high performance standard and no services are missed.

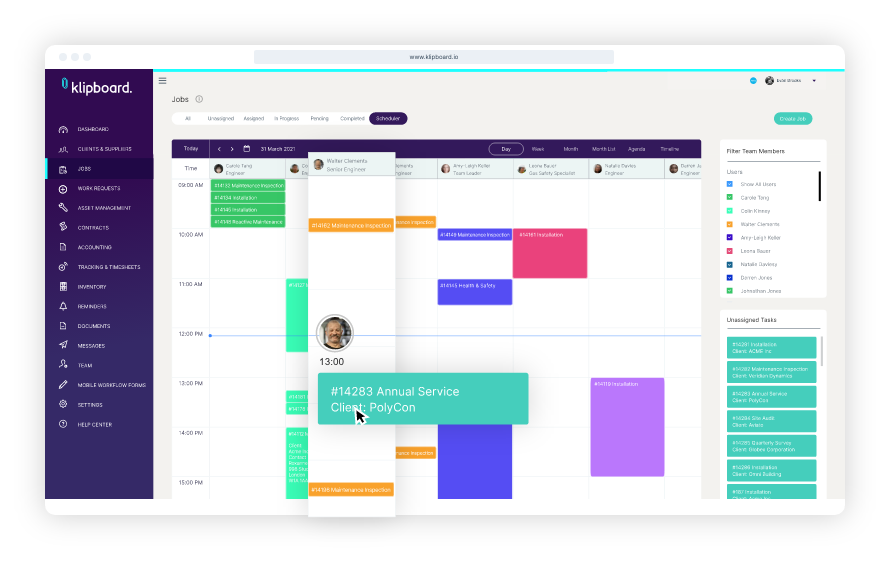

Construction Service SoftwareWhen Construction businesses need to have complete visibility of the projects they are working on and the allocation of resources, they use Construction Service Software.

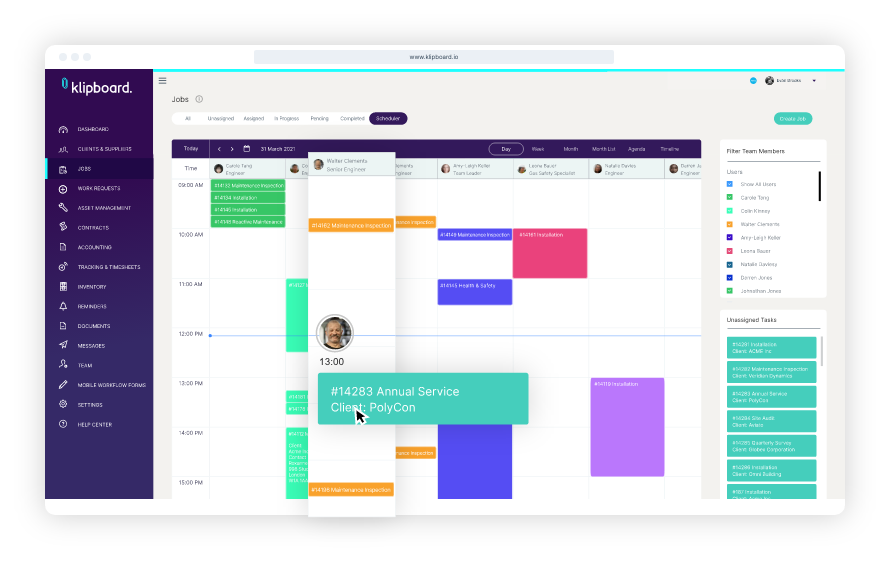

Construction businesses can use drag and drop scheduling to place their team where they need to be.

Construction Service Software will allow them to attach notes, photos and diagrams, that means their team will arrive on site with all the information they need.

Contact CentreA Contact Centre or Call Centre is a centralised office or group or people whose primary responsibility is to manage a large volume of phone enquiries. Traditionally these were set up to manage inbound calls, however software is changing how people interact with businesses and services and a shift to online support is becoming more common.

Expectations of customers are shifting towards online communication and app updates, this puts less pressure on Contact Centres to handle large volumes of calls however there is an expectation from customers to get an immediate response.

Contract LeakageThe difference between what revenue was expected from the agreed contract and what was actually achieved after delivery is the Contract Leakage. The most common cause of Contract Leakage in Field Service is invoicing errors, price adjustments in materials from the point of quoting and then delivery, non-compliant work, delivery or standards failure.

Field Service businesses can avoid these most common reasons for Contract Leakage by ensuring their quoting and invoicing systems are linked to their

Job Management Software, ensuring no delays or mistakes in data entry. Non-compliant work can be avoided when consistency is built into the process with workflow forms.

CP12 CertificatesTo let a property a Gas Safe Registered Engineers needs to make an inspection and product a CP12 Certificate. This ensures the property is safe and all tenants are protected against harmful gases such as Carbon Monoxide and equipment such as the boiler is in good condition.

Once the engineer has made their inspection and ensured everything is safe they can issue a CP12 certificate which is a legal requirement in the UK. Other countries have their equivalent certifications. To read more on CP12 certificates and how can produce them check our article.

Learn more.

Customer ChurnCustomer churn is the rate at which a business fails to retain their customers. Businesses with high churn rates typically haven't established the value of their service.

In Field Service customer churn is relevant to those on retained services for scheduled maintenance. Contracts that include planned preventative schedules for asset management are at risk of churn if service levels drop.

Customer SupportCustomer support is the range of services to help customers make the most of the product or services they have purchased. These activities include training programmes, troubleshooting and support when updates or upgrades are made to the product or service.

We're very proud of the Customer Support we offer the businesses who use Klipboard. In order to make sure our customers get the most out of their Job Management Software we help them identify what features will have the biggest impact on their business and ensure they are set up from day 1 to get the most out of the software.

DecarbonisationThe term decarbonisation is used to describe the act of reducing carbon usage. The impact a business has on the environment is very important to a lot of business or any size. Changes in energy usage and initiatives such as Net-Zero targets are helping to reduce carbon and are contributing to making decarbonisation an achievable goal for many businesses.

Delivery SchedulesA delivery schedule is an agreement between a customer and a supplier as to how often a product or service will be delivered. These are put in place to ensure there's no disruption of service, either the customer can continue to provide a product or service to their customers, or the upkeep of their physical assets.

These delivery schedules need to be reviewed periodically to ensure the agreement in place works for both parties, the supplier and the customer.

Depot RepairPut simply Depot Repair is when repairs take place away from the customer often in a centralised location and then the asset, product, part or item is returned to the customer.

This has many benefits for both the service engineering company and the customer, as it may improve the speed of repair due to the increased availability of spare parts at the centralised location and it could ensure quality control as in many cases there will be separate inspection teams approving the repair.

Dynamic Scheduling SoftwareMany Field Service businesses will be familiar with scheduling software. Dynamic Scheduling involves the use of smart software making decisions on the allocation of field service team members. The software will take into consideration the availability of team members, the skill sets available and the location of that individual to pick the right person for the job.

Earning before Interest, taxes, Depreciation and amortisation (EBITDA)EBITDA or earnings before interest, taxes, depreciation and amortisation is the measurement to assess the financial performance of a business. Although this is a good way of assessing how a business is performing it doesn't factor the cost of capital investments such as property, plant machinery and equipment.

Often the EBITDA is used to compare companies' financial performance against each other and to assess industry averages. EBITDA can also be used to estimate the cash flow available to a business when paying the debt of long term assets.

Employee Safety assessmentsEmployers are obligated by law to prevent risks to their employees. This is vitally important to the Field Service industry where the location and conditions of the workplace change regularly. Businesses must carry out Employee Safety Assessments so they can identify hazards and whether actions need to be taken to improve the safety conditions for their team members.

If you employ 5 people or more people you must carry out a risk assessment on your workplace and record the hazards, who is at risk and the actions taken to mitigate the risk. For more on the laws in place to protect your employees from risk

check out this article from the HSE website.

Engineering ComplianceEngineering Compliance helps ensure assets and equipment are performing at acceptable levels to create safe conditions. Failure to ensure equipment meets specific regulatory standards can result in asset breakdowns or work the risk of legal action.

Many Field Service industries require the Field Service Engineer to test for harmful or hazardous substances.

HVAC businesses for example need to test for fluorinated greenhouse gases (known as F-gases). Their industry is highly regulated, much like the Water Treatment, Fire Safety, Security and many others. They have to ensure the correct checks are being made every time so their clients who own the assets remain complaint.

You can read more on how to ensure compliance is achieved by using a Field Service Engineer App like Klipboard.

Learn more.

Enterprise communication toolsEnterprise communication tools help businesses share internal information, help boost collaboration between employees and their teams and can help businesses better communicate with their customers and stakeholders. Field Service business and home based workers benefit greatly from Enterprise communication tools, where traditional methods of communication aren't available.

We have integrated communication technology into our Job Management Software. This helps Field Service teams better communicate with their customers. It will inform them when they have a service due or when they are on route to visit their site. Click here to read more about

SMS and email communication through our software.

Facilities ManagementFacilities Management is the professional discipline of supporting organisations through the supply of services relating to creating productive environments. This can be through delivering scheduled maintenance, introducing technology to increase productivity and reduce environmental impact, managing security services, maintaining health & safety and public and social housing support.

Field DispatchThis is a phrase used to describe the act of dispatching a field service engineer or technician to service or inspect a client's asset or equipment. When a Field Dispatch support team is notified of an incident, breakdown or problem that can't be resolved over the phone, they will dispatch an engineer to the customer.

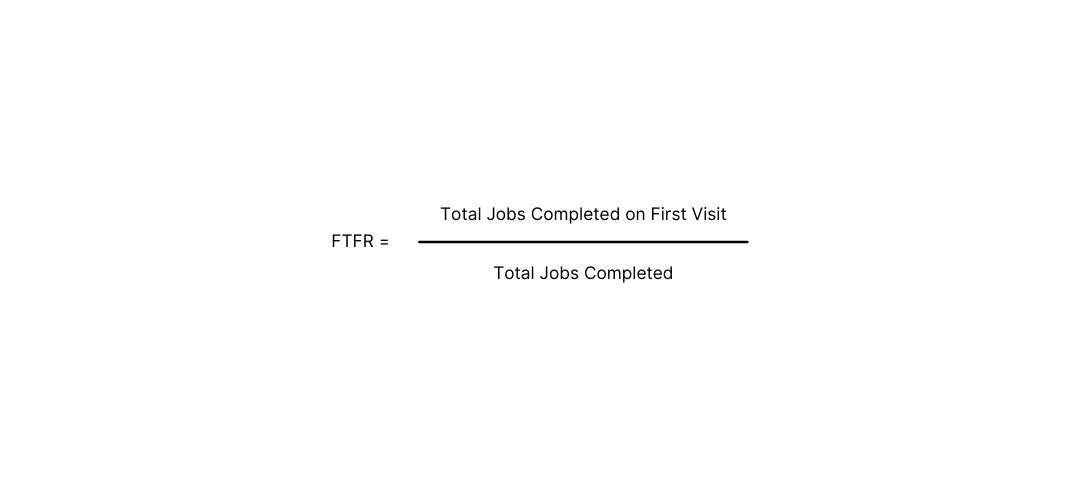

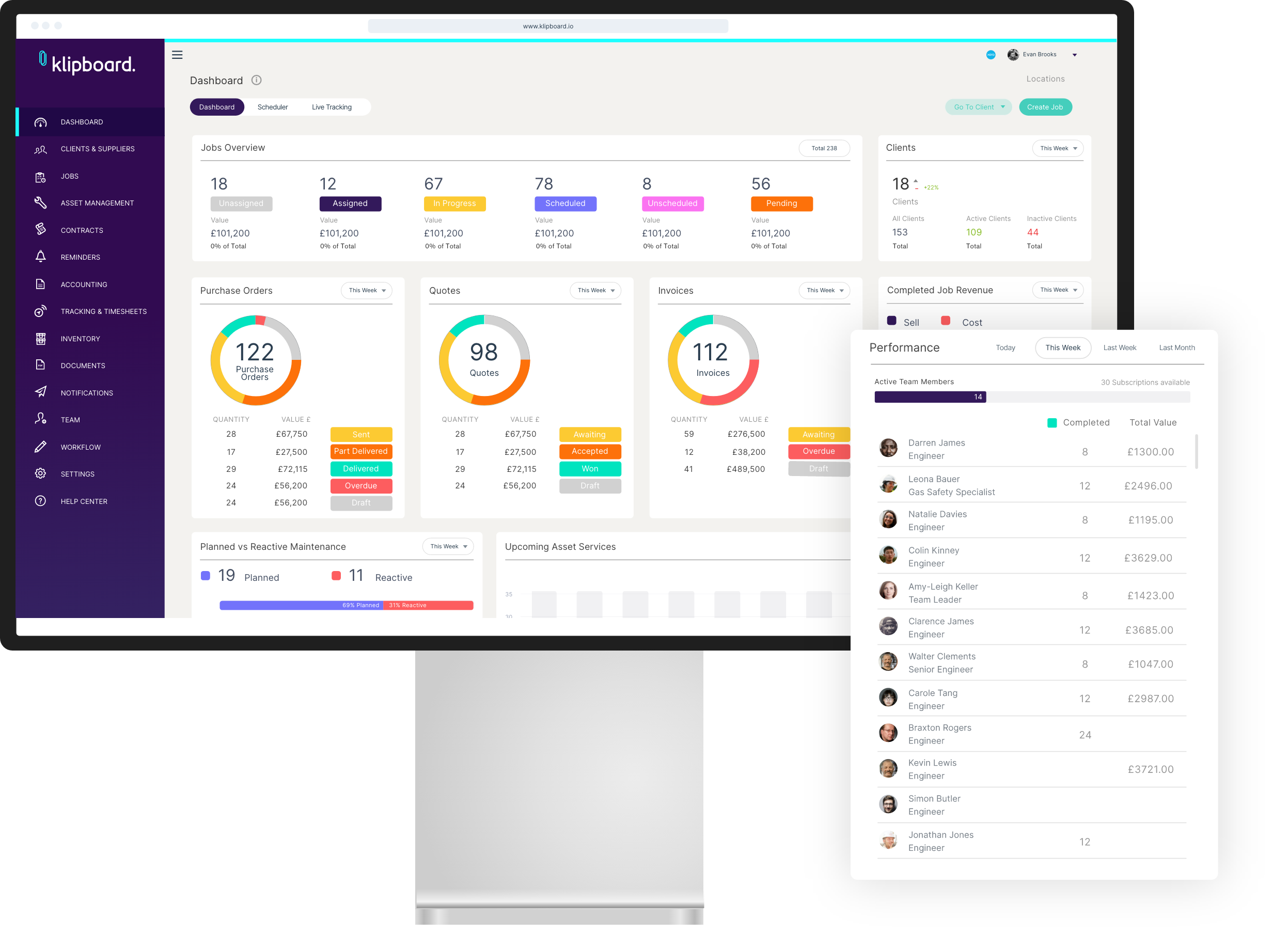

Field Service AppsField Service Apps are designed to improve the efficiency of Field Service businesses. There's huge variety in the features available between Field Service Apps and many are designed to service specific industries. Most will include some form of job scheduling and dispatch tools, some may include the ability to manage client Assets through the app and also offer Field Service Finance integration for businesses who need to create quotes and invoices for their work.

The aim of these Apps is to reduce the workload of field engineers, leaving them to focus on completing more jobs, spend more time servicing their clients and improve the communication between the office and field.

To find out Why Klipboard is the best App for Field Service businesses who want to streamline their operation, reduce their admin, complete more jobs and improve their cash flow

click here.

Field Service Engineer SoftwareField Service Engineer Software improves the productivity of engineers and technicians who service their client's assets or perform compliance assessments and inspections. It's used to better schedule their workload and empower them with all the documents they need to deliver a great level or service.

The features between Field Service Engineer Software may differ from one provider to the next. Some engineers may require a more comprehensive suite of features such as report writing for compliance reports and others may need powerful asset management tools.

Klipboard is the best option for Field Service Engineer Software because it can greatly reduce the amount of admin an engineer and the office team needs to produce, the asset management tools make scheduling planned maintenance schedules simple and the excellent report builder helps engineers to make branded reports to their specifications.

Click here to find out more.

Field Service IndustryThe Field Service Industry is one of the largest and fastest growing industries. It can be defined by work carried out at a customer or client site and often involves the repair, planned preventative maintenance, installation or inspection of equipment or 'assets' in the field.

The Field Service market is expected to grow to nearly $8 billion by 2026 and much of that growth will be driven by the need to offer remote solutions to businesses who's operation expand beyond on centralised location. There's a huge variety of exciting roles within Field Service and it's drive for greater efficiency, environmental impact and skills development has meant it's become a leading industry for innovation and introducing new technology to service their clients.

Virtual and Augmented Reality, Smart Machines, The Internet of Things,

Productivity Software and Building Management Software are just a few of the ways Field Service businesses are innovating.

Despite being a fast growing industry the Field Service industry is not without its challenges.

In a recent survey carried out by Klipboard, we found out that finding new business, managing their team's workload and communicating with their client are their biggest obstacles. Many are turning to field service Job Management Software to meet those challenges.

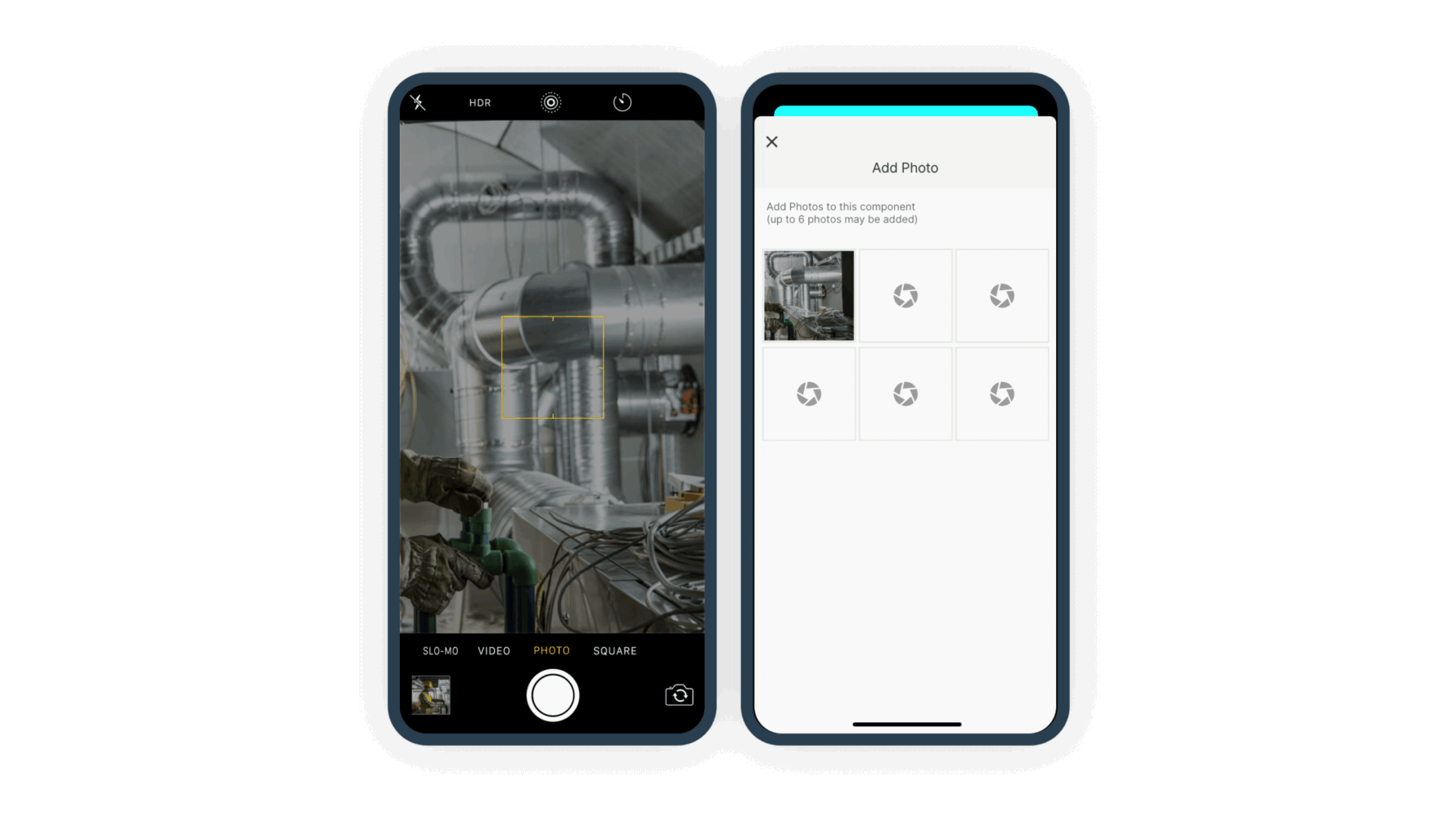

Field Service InspectionsNot all Field Service tasks involve the repair, replacement or maintenance of equipment. Many Field Service businesses produce reports from the inspections they carry out at their client's locations.

Fire Protection Services Businesses for example, produce reports from their health and safety inspections of passive fire protection equipment found at their client's sites. These reports help their clients meet compliance regulations and keep the buildings and the occupants safe. Field Service engineers play a vital role in keeping the general public safe.

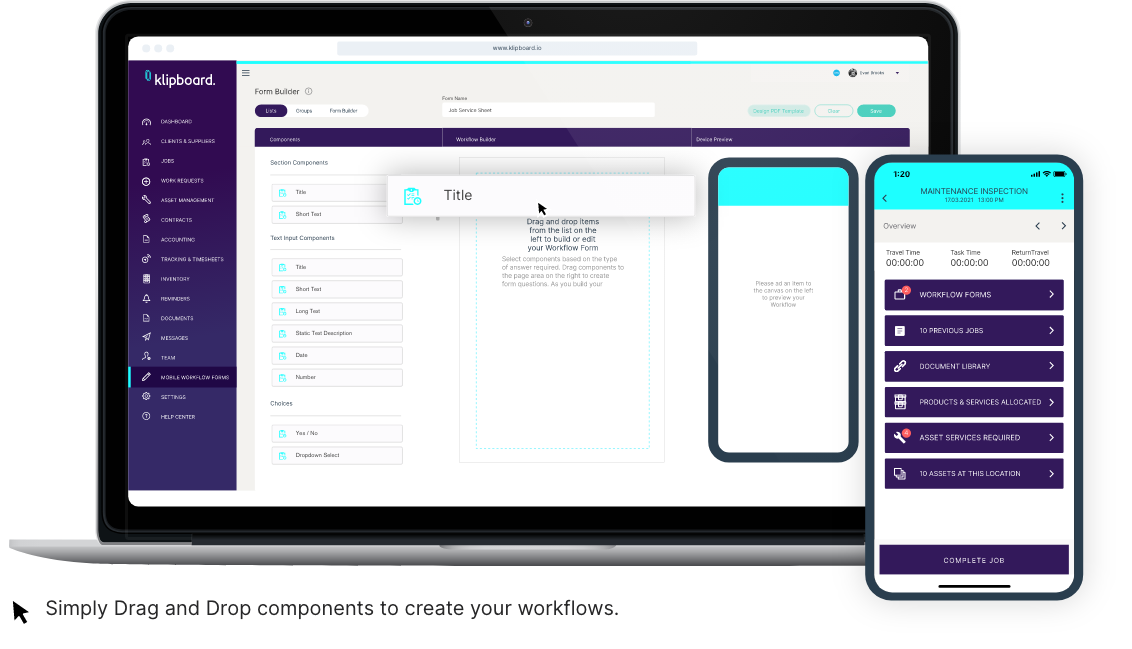

Klipboard helps these businesses produce their own

workflow forms and bespoke forms for their engineers to complete on site.

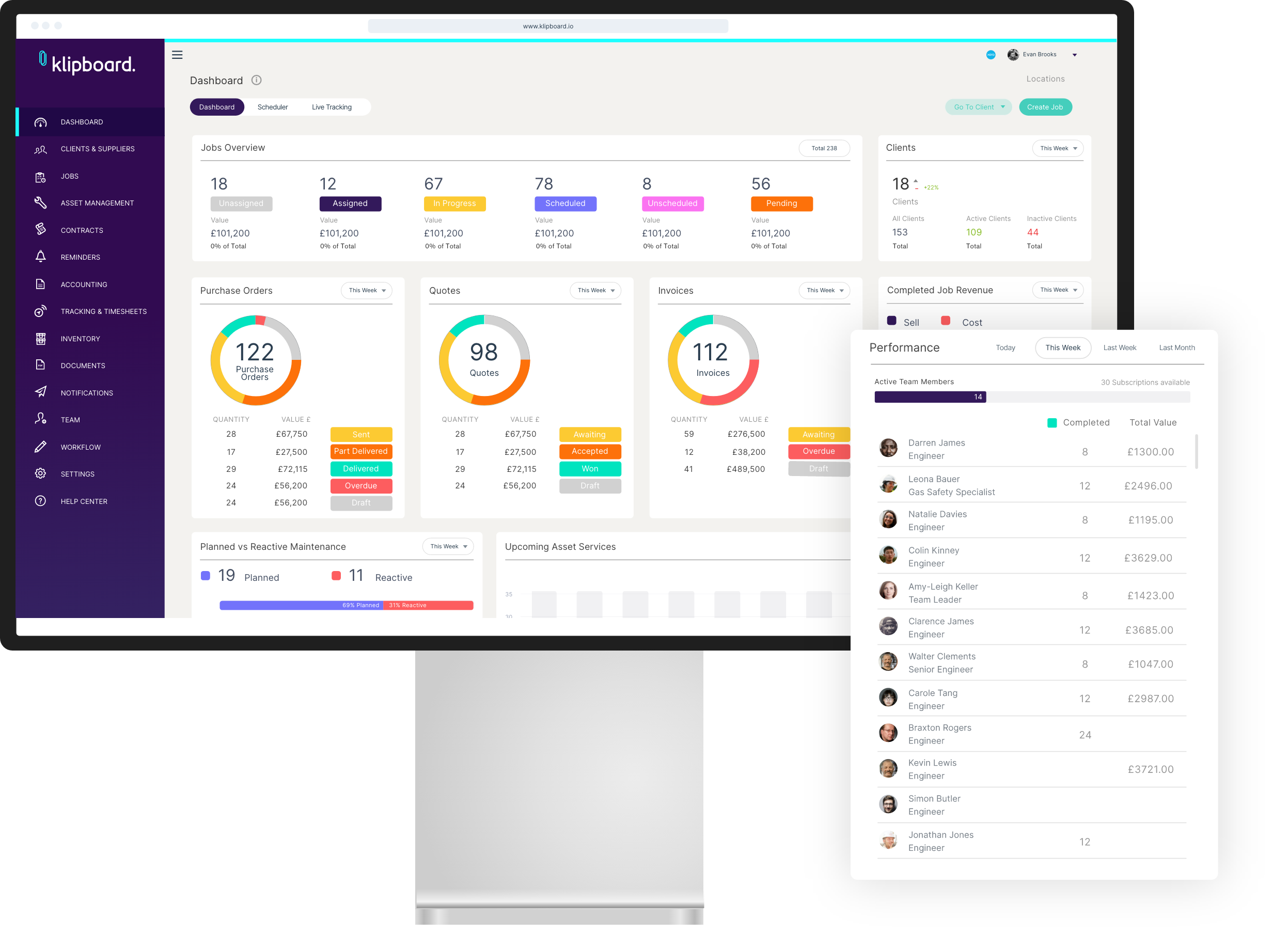

Field Service Management SoftwareField Service Management (FSM) Software is used to manage the servicing of client assets and complete field service jobs more efficiently. It helps simplify the job scheduling process while giving field teams greater clarity of the jobs they need to do. Good FSM software should streamline a field service business operation and help them complete more jobs which will increase cash flow and revenue.

The FSM software market is expected to

grow by around 18% by 2025. This has been mostly boosted by the Covid-19 pandemic which has put extra strain of Field Service businesses and push them to find operational efficiencies to meet demand. FSM software has allowed them to free up more time by spending less of it on admin and complete more jobs.

You can find more details on what Field Service Management is here.

Learn more.

Field Service OptimisationOptimisation is a key focus for Field Service businesses. They are often time starved and their client's growing demands put strain on their ability to continue to operate at peak performance. For Field Service businesses to optimise their operation they need a top down approach to how information is shared around their business and they must put their customer in the certain of all decision making.

The flow of information from the office to the field is often the bottle neck which creates delays, misinformation, human error and slows cash flow - the life blood of any Field Service Business. Real time access to information and the ability to react quickly to the demands of their customer will help them meet the expectations of their clients.

Field Service Report SoftwareField Service businesses who need a structure way of producing reports for inspections and data collected from their client's site use Field Service Report Software. This software helps them control what data needs to be collected, ensuring consistency and compliance for their clients.

Having Field Service Report Software is a key benefit of using Job Management Software. It removes human error and creates a data trial that's easy to follow to ensure your team is collecting vital information in the field. The end result is a report that meets the requirements of your client and if you use Klipboard you can build these to whatever specification you need,

with your brand and logo on the report.

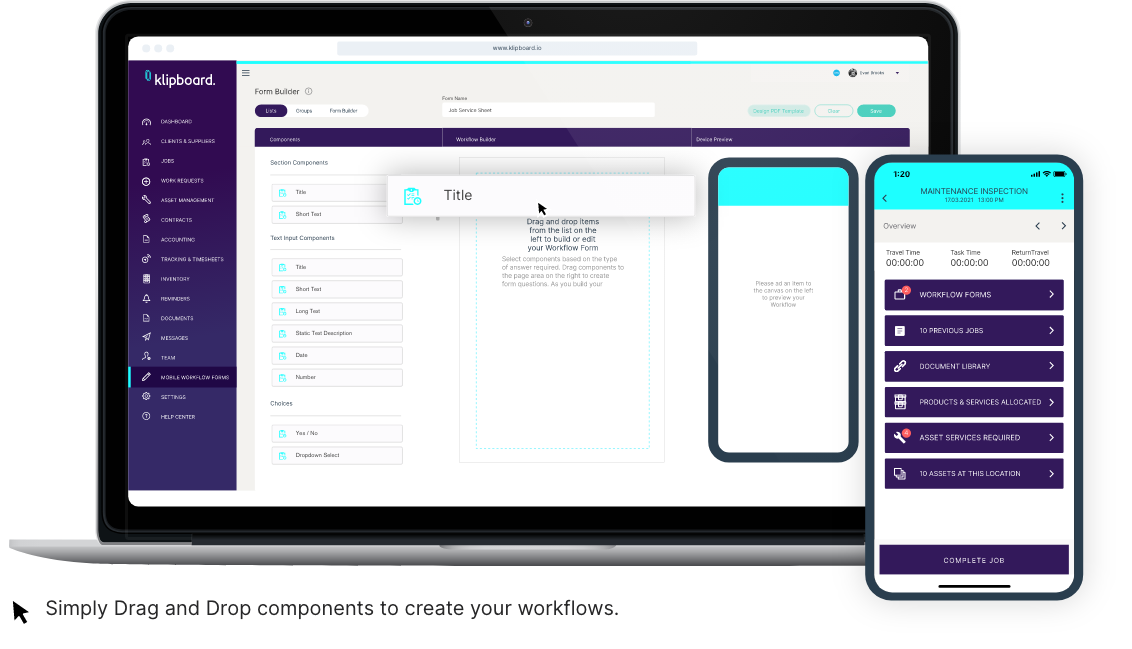

Field Service Report TemplatesField Service report templates are used by engineers and technicians to create standardised and consistent reports for their business. Creating these reports from a single template helps them ensure their client remains compliant. They can produce a report by pulling through the correct information collected on the job through workflow forms.

Klipboard helps simplify this process by offering standard frequently used templates and should you need something a little more bespoke you can easily build it with our intuitive

drag and drop report builder.

Field Service ReportingEngineers and Technicians in the field collect a great deal of information. Field Service businesses can report on what their team discovers in the field by using Job Management Software and

smart report building tools.

Being able to collect and record data accurately while on site in a structured format allows Field Service Businesses to offer their clients and their internal stakeholders all the information they need to make better decisions.

Field WorkersField Workers are the term commonly used for Field Service engineers, technicians and professionals who carry out tasks at client locations. Their roles are as varied as the Field Service industry itself. Ranging from HVAC engineers carrying out scheduled maintenance on air conditioning units to Biomedical Field Engineers calibrating sophisticated healthcare equipment.

Their roles are vital to the ongoing success of their clients who rely on them to maintain their business critical equipment. Field Workers are excellent problem solvers and are often expected to use their technical knowledge and experience to come up with solutions to unexpected problems.

Fire Protection SoftwareFire Protection Software allows Fire Safety Engineers to easily gather information from inspections and turn that data into reports. The contents of these reports ensure a building or location meets fire compliance regulations. The software allows for improved team scheduling, access to customer information, customer history, documentation and with Klipboard the ability to create custom built forms and workflows so the team collects exactly the right information on site.

With Klipboard you can send the jobs directly to a Fire Safety engineer's mobile app and update the office in real time, without the need to duplicate the reports later. For more on Fire Protection Software

click here.

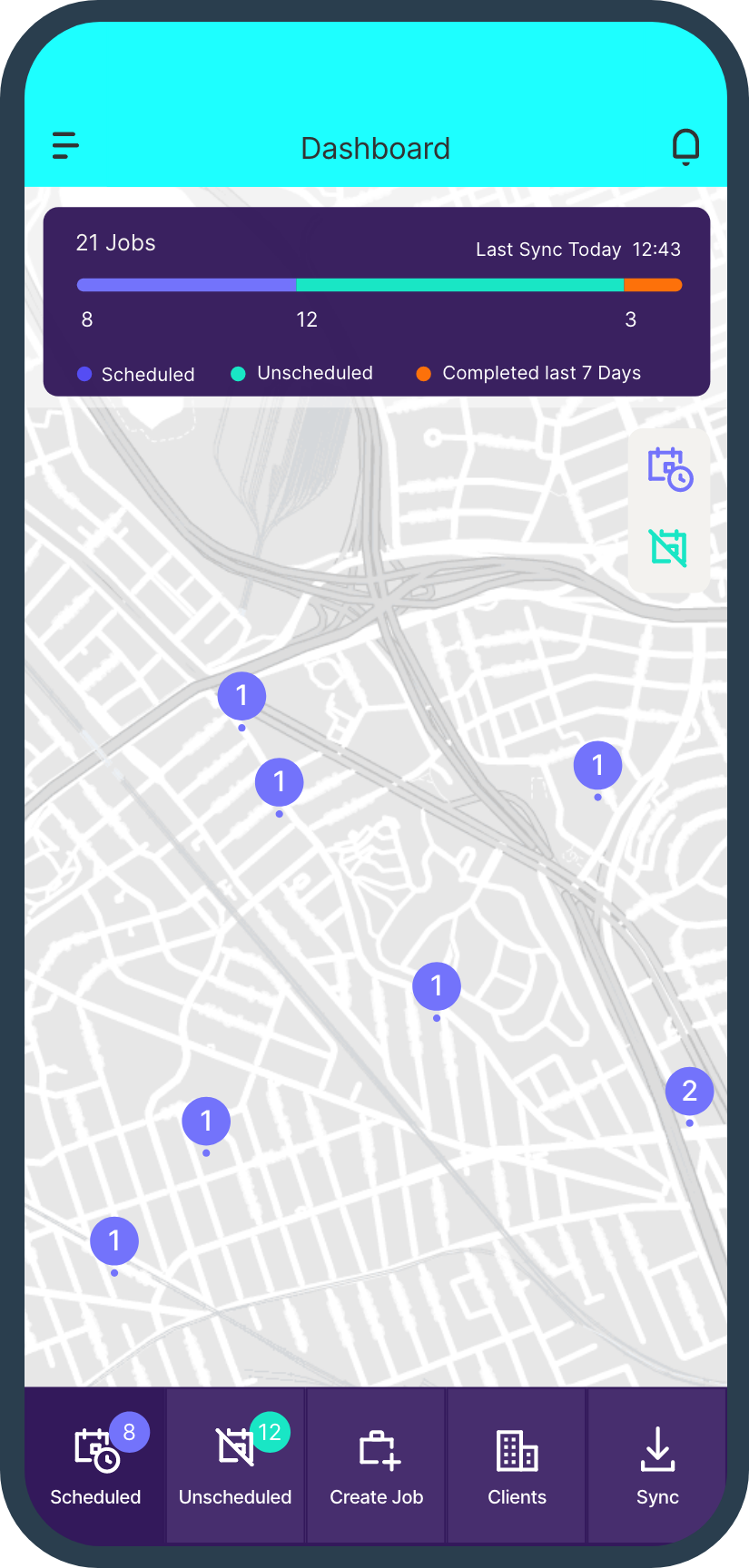

First Time Fix Rate (FTFR)First Time Fix Rate is the number of service requests resolved during an engineers first inspection or client visit. The ideal goal is to fix and achieve as much as possible in the initial visit, doing so has a significantly positive impact on customer satisfaction.

The top 20% of fastest growing and most successful Field Service businesses have a First Time Fix Rate of around 80%. There is a direct link to the success of a Field Service business and their engineer's ability to identify and solve an issue during their first visit.

You can measure your First-time Fix Rate by using a simple formula. Take the number of jobs your team complete in their first visit and divide that by the number of jobs completed and that's your First-time Fix Rate.

You can read more on what your First-time Fix Rate should be and what you can do to increase it by reading our article.

Learn more.

Fleet ManagementFleet Management is the management of commercial vehicles, forklifts, private vehicles and aviation machinery. Effective Fleet Management involves managing the life cycle of the vehicles, improving the efficiency of scheduling, improve the productivity of those using the vehicles and ensuring compliance with legislation.

Heavy Equipment MaintenanceHeavy Equipment Maintenance is the process of ensuring that equipment such as commercial plant, industrial, urban planning and landscaping remains in good condition to ensure equipment downtime is minimised.

When Heavy Equipment remains non-operational it eats into the profits of the businesses that use them. Replacing the equipment can be a time consuming and costly affair. Getting a replacement crane to a construction site is no simple task, so a planned preventative maintenance schedule is required to keep them operational.

Install BaseIn Field Service Install Base is a relevant measurement of pre-existing equipment or software installed at a customer's location. The Install Base of equipment already in possession needs to be considered if systems the engineer are assigned to work on are connected.

Internet of Things (IoT)The term IoT is used to describe devices connected to the internet which effectively ‘talk’ to other devices or systems. The information gained from these devices is used to make smarter use of that device, make other systems work more efficiently or even carry out tasks. The IoT is going to play a pivotal role in Field Service and future of preventative maintenance. We've already started to see the influence of IoT with the inclusion of sensors and feedback to maintenance businesses on their client's assets.

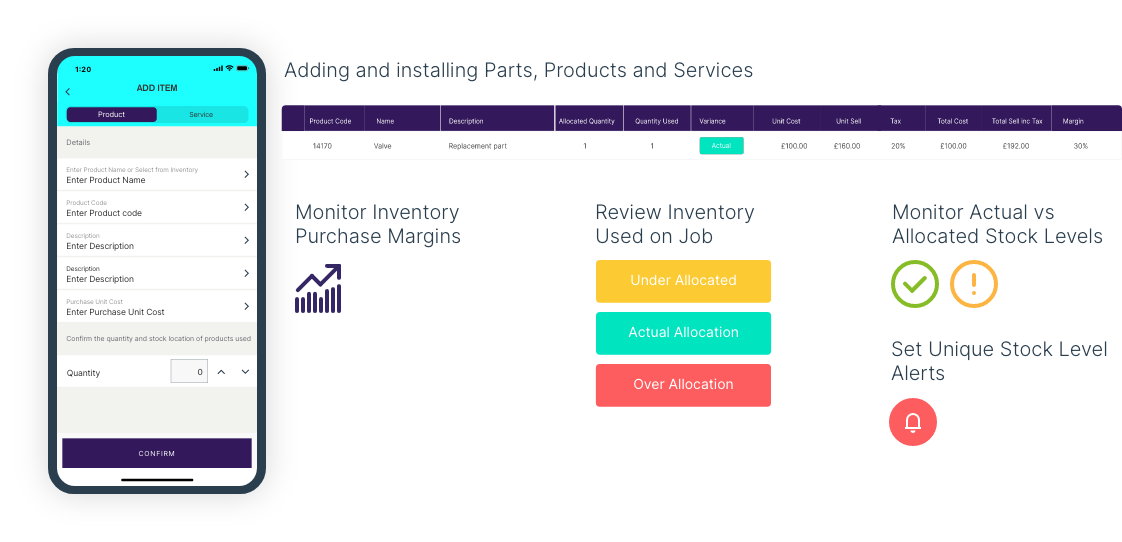

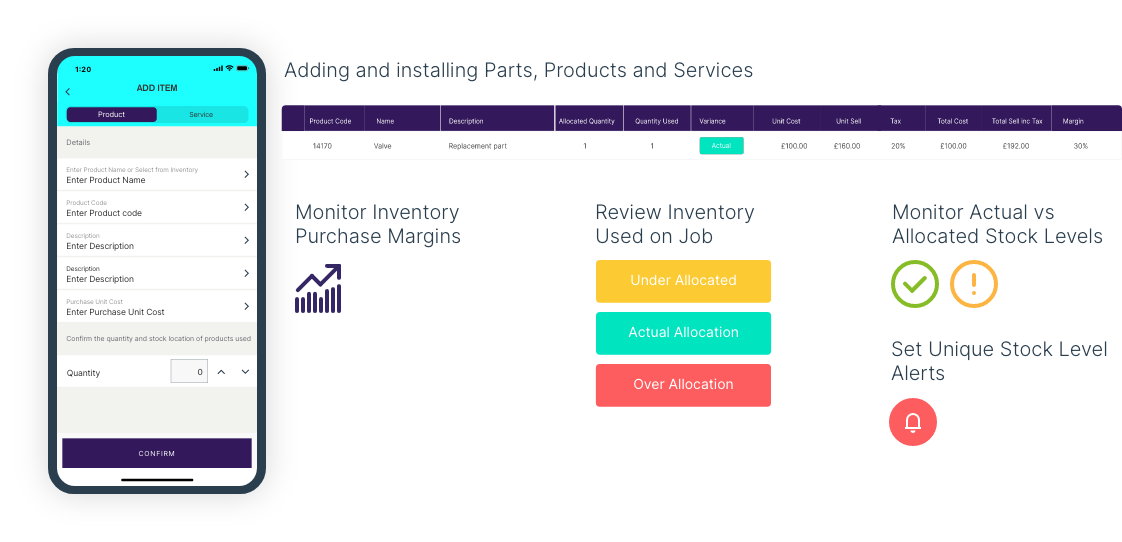

Inventory Management SoftwareBusinesses who need to track how many items of a part or product they have available use Inventory Management Software to get total visibility of what's available. Whether their own teams or their customers are using or purchasing these parts or products, it's important to have a clear and accurate picture of what's available. Other benefits of using Inventory Management Software include the ability to spot trends of a particular item that's being replaced more often, which might indicate a failure, or spotting low stock items before they run out leading to delays in repairs or services.

Klipboard incorporates Inventory Management into our Job Management Software for Field Services businesses. We have created a platform that will not only help you manage your jobs but also ensure your team has their parts and materials they need to get the job done, whether that's a routine maintenance inspection or a complete repair from a breakdown. You're able to see what's in stock and more importantly what location that stock is held in, such as depots, warehouses and even vehicles.

You can see more on that here.

Job Management SoftwareJob Management Software improves the productivity of engineers, technicians and Field Service Professionals who service their client's assets or perform compliance assessments and inspections. Effective

Job Management Software is used to schedule jobs and ensures everyone has the documentation, manuals, floorpans and drawings they need to do their job to a top world class standard.

The features between Job Management Software differ from one provider to the next. Some engineers may require a more comprehensive suite of features such as report writing for compliance reports and others may need powerful asset management tools.

Klipboard is a stand out option for Job Management Software because it can greatly reduce the amount of admin an engineer and the office team needs to produce, it helps streamline Field Service operations and the excellent report builder helps engineers to make branded reports to their specifications.

Job SheetsJob Sheets include all the information Field Service worker needs to carry out their job, they can record the tasks carried out on the job and what materials have been used. They are significantly important to Field Service Businesses because they create an information log what's happened on the Job.

In modern times Job Sheets have been replaced by

Mobile Forms on Field Service Software. Using templates and workflows Field Service businesses have been able to speed up the process of collecting information and more effectively sharing that information with the rest of the team in real-time.

LogisticsLogistics is the overall process of how products and resources are acquired, stored and transported to the end customer. To run an effective logistic operation, attention needs to be given to identifying reliable distributers and suppliers of products of an acceptable standard. Logistics businesses vary in size from small delivery services to large scale Warehouse and Depot goods holding and transportation.

Field Service businesses are directly affected by the effectiveness of the logistic operations around their business. Where they acquire their parts and how quickly they can restock on items which are pivotal to the upkeep of their clients assets.

Machine AvailabilityMachine Availability is a term typically used to describe the operational effectiveness of assets and machinery. Machine Availability Rate is the percentage of time equipment is available divided by the maximum time it should be available in the event there wasn't any downtime for repair or unplanned maintenance.

Here's an example of a Machine Availability Rate:

Operating Time/Planned Availability = Availability %

450 mins / 500 mins = 90% availability

Medical Equipment ServicingMedical Equipment Servicing are the services provided by Field Service Engineers who specialise in maintaining healthcare and Biomedical equipment for their clients. Often this equipment is found in hospitals, Emergency Wards and Specialist Clinics. The performance of the equipment directly affects the quality of care for patients, this is why it's vitally important for these businesses to use Field Service Engineers who can ensure downtime is kept to a minimum and the machines operate at peak performance.

Planned Preventative Maintenance (PPM) scheduling plays a crucial role in keeping the availability of medical assets at the highest rate. For more on how PPM schedules are vital for Medical Servicing Businesses

check out our article.

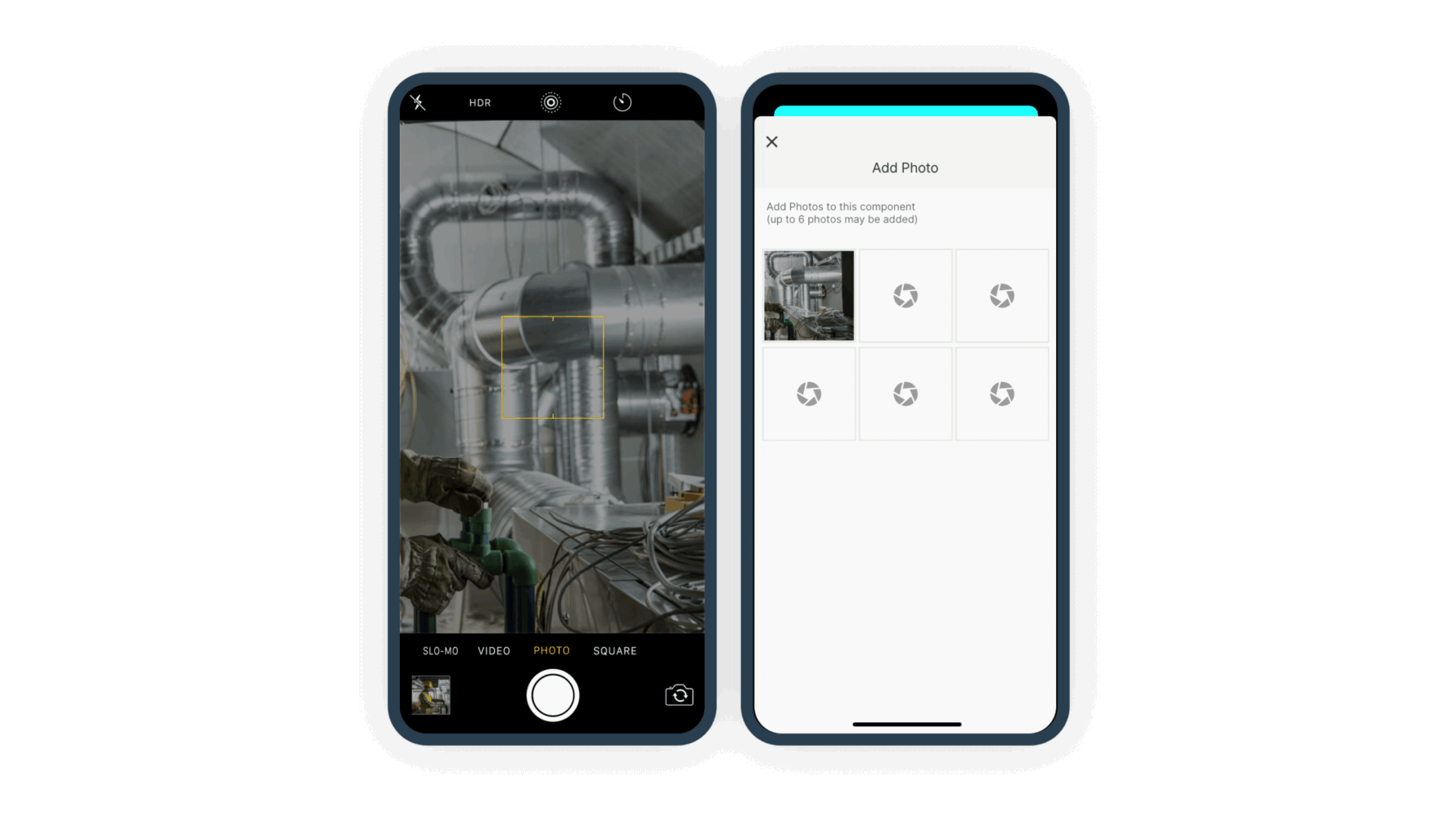

Mobile FormsMobile forms are digital forms created to be used on mobile phones and tablet devices so Field Service Engineers and Technicians can collect data in the field. They provide Field Service business provide a consistent and easily accessible way of gathering information and completing jobs. The data collected can be used to build reports or feed into other tools to give insight into your business and better support your customers.

For more on how Mobile Forms can benefit Field Service businesses,

check out this article.

A mobile form should be easy to complete on all devices and be adaptable to different industries. A Lift Engineer will need to record different data to a Fire Safety Consultant for example, but they both will need to be able to log data at their client’s location.

Mobile WorkforceA Mobile Workforce is the term used for team members who operate on location at their client's sites rather than an office or physical location. Technology plays a huge part in how a Mobile Workforce can access the information they need and how they can communicate with stakeholders and colleagues. Affordable and reliable technology has helped digitalise the activities of a mobile workforce with mobile phones and tablets.

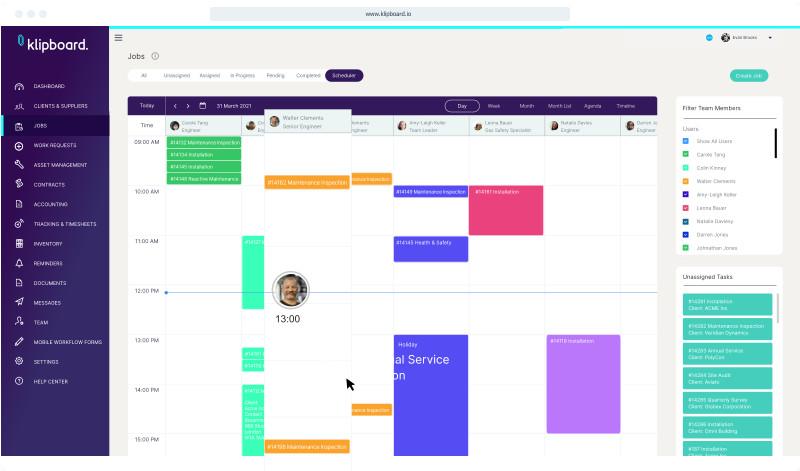

Mobile Workforce SchedulingA smart scheduling system is required for Field Service businesses who need to complete planned preventative maintenance and react swiftly when they are required for a call-out.

Typically Mobile Workforce Scheduling updates the team in real-time so Field Service businesses can allocate engineers or technicians to jobs who are both available and local to the job.

Many scheduling software systems offer a drag and drop

schedule and dispatch function. This is particularly helpful for management teams who have multiple engineers who need to attend.

Net ZeroIf you work in building services or Facilities Management you'll come across the phrase Net Zero.

It is a global initiative to reach

net zero emissions by 2050. To achieve net zero businesses will need to consider the impact their business is having on the environment and take actions to reduce carbon emissions.

Many businesses are already looking to renewable energy sources to power their business or create environmentally friendly places of work. Field Service engineers who work in industries supporting these businesses will need to consider how the assets and equipment they maintain and service for their clients will change over the next few years.

Environmentally conscious business owners may review the impact their business partners and suppliers have on CO2 levels. Successful Field Service businesses of the future may need to review their own processes and choose to work towards the common Net Zero goal.

Not to Exceed (NTE)In Financial contract law Not to Exceed or (NTE) is the predetermined maximum cost for products and services or the maximum time spent on the project as quoted by the Contractor. The agreed costs assume the scope of the project does not change.

Occasionally this might be written at Time and Materials agreements (T&M). Many Field Service businesses prefer the Fixed-fee project costing approach, as the T&M or NTE model imply a shared risk. If things change on a project or the client decides to add the the score the client will incur further costs based on the additional time and not the end result.

Off-site ConstructionOff-site construction is the process used where parts of a project are built or constructed at a location, different to the where the finished building will be situated.

This method of construction is gaining popularity due to the cost effective nature of Off-site construction, the increased time efficiencies, improved safety for construction workers and higher standards of quality control.

On-demand serviceWe are all becoming more familiar with On-demand service or ‘Software as a service’ models as they are being found in all aspects of our work and home life.

An On-Demand service is a term used to describe a service instantly available, at any time you need it. This is found in TV streaming services, taxi booking services and your Field Service

Job Management Software.

Parts Inventory Management SoftwareA Parts Inventory Management Software system is designed to reduce the maintenance cost of assets, reduce inventory shortages and encourage a more cost effective approach to maintenance.

Most Inventory Management Software systems allow you to gain more control over the supply chain of your parts and products. Having greater visibility of your stock levels helps you to avoid running out of parts required to complete repairs.

Klipboard Job Management Software includes an Inventory Management Systems that also allows you to manage stock across multiple locations. This is particularly useful for Field Service Engineers where parts could be spread across various depots, storage centres and even vehicles.

Passive Fire ProtectionPassive Fire Protection are the components or products used to structurally protect a building from fire and keep their occupants safe.

Fire Safety regulations and certification differ country to country but all support the most important goal which is the protection on life.

Examples of Passive Fire Protection testing certification and regulations by region:

- United Kingdom: BS 476

- Germany: DIN 4102

- Netherlands: NEN6068

- United States: ASTM E119

- Canada: ULC-S101

- Australia: AS1905.1-2005

Passive Fire Protection such as Fire-Resisting Doors, Fire Shutters, Suspended Ceilings and Fire-Resistant Glazing all need periodic testing and inspection to meet their code.

Fire Safety Compliance specialists are commissioned to do scheduled testing to ensure the building owners meet compliance regulations.

PassivhausBuilding developers are becoming more aware of their impact on the environment. Passivehaus or Passive House is a highly energy efficient building standard and has become a leading building standard.

Particular care and attention is given to the thermal insulation of the building. The heat the building contains and the airtightness of the property dictates whether it meets Passivehaus standard.

Developed in the 1990s by Professors Bo Adamson and Wolfgang Feist in Darmstadt Germany. Passivehaus was initially designed with new build properties in mind, however its expanded to refurbishment projects.

Peak SeasonsPeak Seasons are periods when a Field Service business is at its busiest and this is often dependant on the type of work that carry out.

HVAC technicians experience their busiest periods during extremes in temperatures. In the Northern Hemisphere this is typically from May to Aug for Summer months then Nov to Jan for Winter. This trend is reversed for the Southern Hemisphere.

Drainage companies see their peak seasons during the wet seasons when they experience downpours which put added pressure on drainage systems. While some industries in Field Service have a fairly consistent workload throughout the year with short periods where work stops such as Construction, Building Services and Facilities Management. These are likely to be constantly required throughout the year with only extreme weather and seasonal holidays halting demand.

Planned Preventative Maintenance (PPM)Planned Preventative Maintenance (PPM) is the process of ensuring equipment, machinery or assets are serviced and inspected on a regular basis to avoid downtime.

PPM is frequently used by Field Service Engineers and Technicians and forms part of an ongoing commitment of

asset management between the servicing business and their customers, to ensure their equipment is performing effectively.

Potential faults and failures can be spotted early and avoided when the equipment is regularly serviced. For many client’s any downtime experienced of their assets could have a significant impact on their revenue.

The key benefits of PPM are:

- Longer lifespan of assets and equipment

- Reduced need for unplanned repairs or emergency call outs

- Improved performance of the equipment

- Reduced running costs

- Improved safety management

- Reduced downtime

- Happier clients

Managing PPM schedules is typically done with

Job Management Software, this allows the Servicing Business to book a series of jobs into their engineer’s diary and accompany that with all the information they need.

To read more on the benefits of PPM Schedules

click here.

Preventative MaintenancePreventative Maintenance is maintenance that is performed on a piece of machinery on a regular schedule to reduce the likelihood of failing or breakdowns. A routine sequence of preventive maintenance will ensure parts within the machinery are operating as the should be and will give the engineer or technician an opportunity to spot a potential fail, before the breakdown occurs.

Unplanned downtime is avoidable by using a preventative maintenance schedule. The frequency of the schedule is dependant on several factors such as how the equipment is used, how often the equipment is operational, or sensor based with smart machines.

Usage-based maintenance

If an asset or parts of an asset are known to fail upon a certain number of uses then a maintenance schedule can be designed around the usage of the equipment. For example, if a fan within an Air Conditioning unit is know to after 400 hours, a HVAC engineer can build a plan around the expected time it will take to reach short of that number.

Time-based maintenance

A time-based maintenance plan will schedule maintenance around set dates. A Gym maintenance technician may be required to conduct weekly swimming pool PH and chemical testing. Due to high usage and the health and safety implications a more frequent maintenance schedule is required.

Condition-based maintenance

Condition based maintenance schedules are deigned to be proactive and identify parts of an asset likely to fail. This form of maintenance is changing significantly will the introduction of smart sensors and 5G networks. Field Service Engineers are able to read the real time condition of machines allowing them to plan proactively ahead to order new parts of schedule servicing.

Proforma InvoiceA Proforma Invoice isn’t actually an invoice at all. It’s a preliminary bill or an estimation used to secure commitment from a buyer for goods or services before they are supplied. A Proforma Invoice will include details of the products, parts or services needed for a project or job.

What’s the difference between a quote and a Proforma Invoice?

A quote is often a simple outline of the project or job and the estimated costs. People often use a Proforma Invoice to offer the buyer or client more detail in the transaction. Often a quote will generalise the overall costs while a Proforma Invoice is likely to list all individual costs.

Public TendersPublic Tenders are the procurement process used when the public sector is invited to compete for work. This could be the supply of goods, services, products, works or maintenance with the overall goal of securing the best quality service at the most cost effective price.

Reactive MaintenanceWhile Preventative Maintenance is carried out proactively to avoid downtime of equipment, Reactive Maintenance occurs when a breakdown has already happened and an engineer or technician is required to repair the asset.

Generally speaking Field Service Engineers will try to avoid reactive maintenance by offering their clients

planned maintenance schedules to identify potential reasons for assets to fail leading to downtime.

Downtime of assets is costly for their clients. Often if an asset fails or is deactivated before failing, this will effect the revenue and the continuity service that client offers.

Repair Tracking SoftwareField Service Engineers use Repair Tracking Software to organise their repair jobs. They are able to document the fault, order parts and ensure their customer is offered a swift repair.

Klipboard offers the ability to share information between the office and the repair technician or engineer even while they are on the job.

- Track repairs in real-time

- Ensure health and safety compliance

- Order parts on the go

- Build a complete repair history for the customer

Report Writing SoftwareReport Writing Software for Field Service engineers documents the actions performed and information gathered on a job to create a bespoke report for a customer, all through a single platform.

These customer reports can be issued per job, weekly, monthly, annually or as often as required.

Report Writing Software or Job Management Software that includes a robust reporting function, has become even more widely used in Field Service as the need to share information and quickly access data is becoming more expected.

Field Service businesses have started to ditch paper based methods and turn to software such as Klipboard which offers

a paperless answer to how they can create reports for their clients.

How to write a report:

- Identify the problem or task

- Gather all the required information

- Analysis the information

- Come up with a solution

- List actions and expected outcomes

- Organise the report in a clear format

- Write the report

- Send to customer and stakeholders

Residual ValueResidual Value is the estimated value of a fixed asset at the end of its lifecycle.

In Field Service this can be important with a business has made a significant investment into its equipment. The quality of the maintenance carried out during its lifecycle, can great affect its Residual value. Many Field Service businesses put assets on a Planned Preventative Maintenance schedule to ensure the residual value remains high.

Learn more.

RetentionRetention is Field Service is most likely to be related to the retention of customers. Customer Satisfaction is closely linked to how likely a customer will retain the services of that Field Service business.

How do Field Service business sustain customer satisfaction?

Each client will have their own particular expectations and standards they will require from their business partners and their suppliers. Often the most simple answer is they wish to continue to grow their business and any downtime with their assets is likely to effect revenue.

Field Service business most use a combination of efficient planning and technical knowledge to ensure their clients equipment is properly maintained.

Communication plays a massive role in sustaining high levels of customer satisfaction. The modern customer expects real time information on their jobs and scheduled servicing of their equipment.

This need for real time communication and job visibility for both the Field Service business and their client, is a key reason why Klipboard created the

Client Portal.

The Client Portal is a sharable link that Field Service businesses can send to their clients which allow them to clearly see the status of each job, see any unpaid invoices and approve quotes for future work.

Reverse LogisticsReverse Logistics is the process of returning parts or products from the end user back to the seller, re-seller or manufacturer. It allows the customer to return unwanted parts and is a great solution for manufacturers or installers to re-use or recycle parts and equipment.

What’s the difference between Logistics and Reverse Logistics?

Traditional logistics is the process of delivering a product to a customer in the most cost effective and fastest way. Tracking systems and sophisticated warehouse technology has greatly improved the efficiency of logistic operations over the last few years. Reverse Logistics relates to goods moving in the opposite direction from the end user back to the seller or manufacturer.

Route OptimisationRoute Optimisation is the process of identifying the most efficient way of getting from one location to another. In Field Service considers more than just the shortest route from A to B, effective route optimisation also take into factors such as the availability of engineers and technicians.

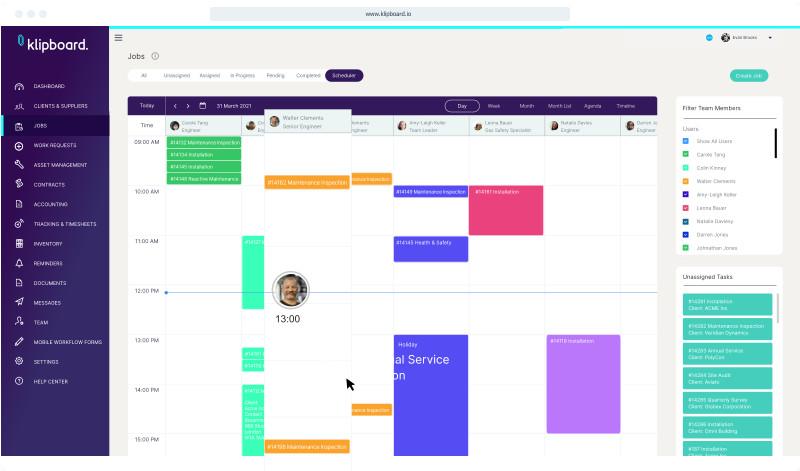

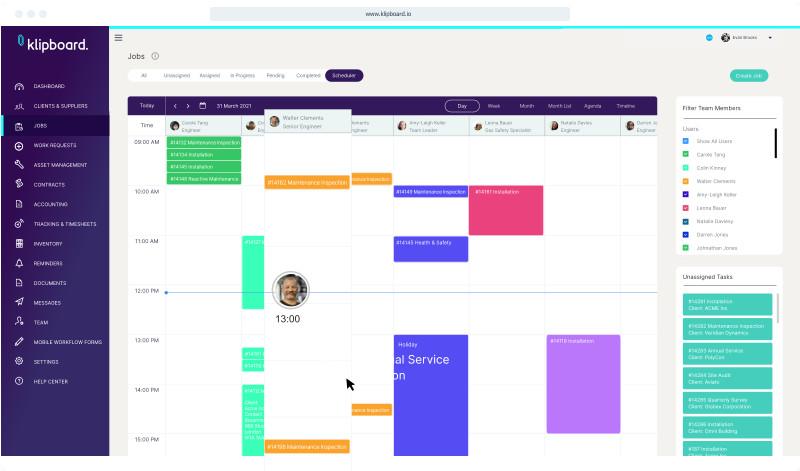

Scheduling SoftwareScheduling Software is used to help businesses optimise job management, employee scheduling or project management. With Klipboard

Scheduling Software you are able to effortlessly track where your team should be, view the expected time they will be working on a job or project and control costs.

Job Scheduling Software is widely used in almost every industry and is particularly prevalent in Field Service where the need to track engineers, schedule and dispatch them to client locations is a daily task.

What are the key benefits to using Scheduling Software?

Real time visibility of your team’s workload is a key reason people turn to Scheduling Software. To ensure you meet your client’s expectations and never miss a job or service, you’ll need to be aware of your team’s availability.

Being able to categorise jobs allows for greater visibility. Creating and manage custom categories allows you to assign these to jobs of a specific type, or if that job uses specific tools or equipment, therefor you’ll know who is available and whether certain equipment is available also.

Service AutomationService automation is the delivery of a service in an entirely automated manner. In terms of software and field service management software it means you’re able to log in and make all the changes and amendments you wish, creating a self-service experience.

Netflix entertainment streaming service is a very successful example of service automation. Uber taxi ordering service changed the way we book a cab with a similar self service model.

Service Call Management SoftwareService Call Management Software helps business more efficiently mange the lifecycle of a service request and allows businesses to track the progress of the job. Without Service Call Management Software a service business can lost revenue due to missed jobs and human error.

What is service call software in Field Service?

For field service businesses, Service Call Management Software or Field Service Management (FSM) software helps businesses deliver onsite servicing and maintenance jobs while effectively managing their team’s workload.

Features commonly found include schedule & dispatch functions, job details, inventory management and field service job quoting and invoicing.

For more on this check out our article.

What is FSM software?

Service CallsA Service Call is the term used when an engineer, technician or team member visits the location where a piece of equipment, asset or group of assets requires servicing, maintenance or inspection.

What does a service call include?

A service call will include the costs of the labour and time for the service, they will also insure travel costs and potentially the costs for parts or disposal of equipment.

What is the average service call?

The average service call fee depends entirely on the work carried out. For home owners or landlords this could be around £50-£100 per hour for an electrician or plumber.

Larger scale businesses will most likely have an ongoing agreement with a Field Service business and a contractual agreement for a certain number of call outs or an agreed fee for a service call.

Service Level Agreements (SLA)A Service Level Agreement (SLA) is a part of a contract that defines actually what will be delivered by the service provider for a job, project or on-going contractual obligation.

What should be included in a SLA?

A well crafted SLA should include the following:

- It should clearly state the objectives of the services provided

- It should describe in detail the service deliverables

- The SLA will define the standards of service

- It should state how those standards will be measured

- It should provide opportunities for review and adjustment of the deliverables

- The customer should have the right to terminate the agreement when performance falls below agreed standards

Service Order Management ProcessService Order Management is how businesses manage the end to end lifecycle of a service request. This may include the process of receiving a request, tracking a job and fulfilling a customer request.

What are the steps in service order management process

To effectively manage a service order request a business will need to well organised and have customer details quickly on hand. Here’s the steps taken when a service order is raised:

- Customer identifies an issue

- Information from the customer is gathered and entered into a system

- A quote is raised if one is required

- A new job record is created if a service visit is required

- An engineer or technician is assigned to the role

- Information of the repair or service is gathered on location

- The office has real time visibility of job progress

- The customer is notified of the status when the job is completed

- Reports are created from the details gathered onsite

- Invoice sent to customer upon completion

Service Tracking SoftwareService Tracking Software is how Field Service businesses are able to optimise the job management of their field teams. It allows them to schedule and dispatch their engineers or technicians to their customer’s jobs, while keeping all the client details, job information and work history in one system.

Software systems like Service Tracking software, job scheduling software are often refereed to as FSM (Field Service Management) Software.

What is FSM software?

Field Service Management (FSM) software helps businesses deliver onsite servicing and maintenance jobs while effectively managing their team’s workload. Features commonly found include schedule & dispatch functions, job details, inventory management and field service job quoting and invoicing.

For more on this check out our article.

What is FSM software?

ServitizationSertiization refers to businesses using their products or services to sell the outcome as a service as opposed to a single transaction.

What are the benefits of Seritization?

It’s widely acknowledged that a Servitization model encourages manufactures and service providers to take ownership and more responsibility for their products. They are responsible for the outcome and the impact of the product, rather than simple selling it.

Smart MachinesSmart Machines, machine learning and Artificial Intelligence (AI) is changing the way Field Service business are able to predict equipment failure and extends the lifecycle of assets.

Smart Machines allow for greater visibility of what’s happening with their client’ assets. Sensors in sophisticated machinery send information back to the engineer to give them details about the condition of the equipment.

Spare Parts ManagementSpare Parts Management is a strategic component of service management. It ensures the right parts are made available to engineers and technicians when they are required. Without an effective Spare Parts Management strategy, assets and equipment could experience unexpected downtime when a part fails and is not immediately replaced.

Klipboard’s

Inventory Management System allows engineers to see the stock levels of parts even when they are across multiple locations. Each location in your Inventory Management is displayed in real time so you’ll know what’s available.

SubcontractingA subcontractor is an individual or business that are hired to perform some part of the overall obligations of the main stakeholder’s contract.

Types of subcontractor

Domestic - A subcontractor who is employed by the main contractor and is contracted to repair or inspect equipment or execute on agreed work forming part of the main contract.

Nominated - When architects, chief stakeholders or supervising officers make the find selection and approval of subcontractors, these are named contractors.

Named - These are essentially the same as domestic subcontractors as they are selected by the main contractor on the project.

Supply ChainA Supply Chain is effectively the activities required by an organisation to deliver goods, products or a service to the customer.

What are the supply chain steps?

In simple terms a supply chain is simply a sequence of steps taken by several parties to delivery a product or a service, here are the steps common in a supply chain:

- Obtaining raw materials

- Refining or manufacturing materials into a workable material or part

- Assembling parts into products

- Selling the product to the end user or customer

- Delivering the product to the customer

Sustainable MaintenanceSustainable Maintenance is the process taken to ensure the lifecycle of assets or equipment is extended by preventing any unexpected downtime or part failure.

The goal of Sustainable Maintenance is similar to Planned Preventative Maintenance. By regularly servicing and inspecting equipment, engineers are able to predict when it might fail and ensure it remains operational for longer.

Technician Scheduling SoftwareTechnician Scheduling Software is used to help businesses optimise job management, employee scheduling or project management. When a business needs improved visibility where their technicians need to be, when they are arriving on site and who will be working on the job, they use Technician Scheduling Software.

Technician Scheduling Software is particularly prevalent in Field Service where the need to track team members, schedule and dispatch them to client locations is a daily task.

What are the key benefits to using Technician Scheduling Software?

Real time visibility of your team’s workload is a key reason people turn to Technician Scheduling Software. To ensure you meet your client’s expectations and never miss a job or service, you’ll need to be aware of your team’s availability.

Being able to categorise jobs allows for greater visibility. Creating and manage custom categories allows you to assign these to jobs of a specific type, or if that job uses specific tools or equipment, therefor you’ll know who is available and whether certain equipment is available also.

Time and Materials (T&M)In Field Service Time and Materials is a term commonly used job estimates when the size of the project cannot be accurately estimated and the employer will pay for work on an hourly or day rate.

A Time and Materials agreement is frequently used in construction and where the scope of a project may change.

Touchless AccessTouchless access is a physical security measure where access can be granted without physically touching card readers, doors or gates. Employees can quickly access a building using smart cards, face recognition or gestures.

Physical security measures are designed and fitted by

Security Installers. They can install a variety of measures to ensure the occupants or visitors of a building remain in a safe and secure environment.

Van StockVan Stock, also known as Truck Stock is the term used for inventory located or stored in a Field Service Engineer vehicle.

Disadvantages of have Van Stock

Van Stock is difficult to audit and count. Field Service businesses will need to rely on their engineers to keep track of the parts they have used and record them accurately.

This leaves Field Services businsseses at risk of parts not being available to other engineers or even over stocking when a proper count isn’t conducted.

How to manage inventory across multiple locations

Klipboard Job Management Software includes a robust Inventory Management system that allows Field Service businesses to gain an accurate picture of the parts and inventory they have even across multiple locations.

Having the right parts available will greatly improve the First Time Fix Rate (FTFR) of assets and increase customer satisfaction.

Warranty Tracking SoftwareWarranty Tracking Software identifies assets or equipment and monitors the warranty expiration date. This allows for greater visibility of expiring warranties and the Warranty Tracking Software will automatically notify when a warranty is due to expire.

Work OrdersWork orders are a request for a repair, maintenance or inspection to be completed by a Field Service Engineer or Technician.

Work orders are created when the customer or client submits a request, this could be a staff member, tenant, facilities manager or business owner.

What is the point of a work order?

Work Orders notify a service business that a task or job is required and will clarify specifically what work needs to be carried out. These can include requested dates for the work or special instructions as needed.

Workflow formsWorkflow forms are used by Field Service engineers and technicians to standardise the tasks carried out ensuring compliance and consistency of work.

Why Field Service businesses use Workflow forms

Workflow Forms are used in service engineering to ensure the correct procedures and steps have been taking while repairing or inspecting equipment.

For many businesses they have to meet strict compliance regulations to meet their standard and Workflow forms ensure the tasks that need to happened get done.

How are Workflow forms built?

Job Management Software has significantly aided Field Service businesses when creating Workflow Forms.

Drop and Drop form builders have simplified the process of recreating paper based methods.

Advantages of digital Workflow forms

People are moving away from paper based methods because misinformation and human error has proven to be costly to Field Service businesses.

Klipboard has helped Service Engineering businesses step away from old fashioned systems and put all their job tasks into an all-in-one platform.

Collecting information in the field is simple with mobile forms and consistency is ensure when digital Workflow forms are used.

For more on this check out our article:

What are mobile Forms?