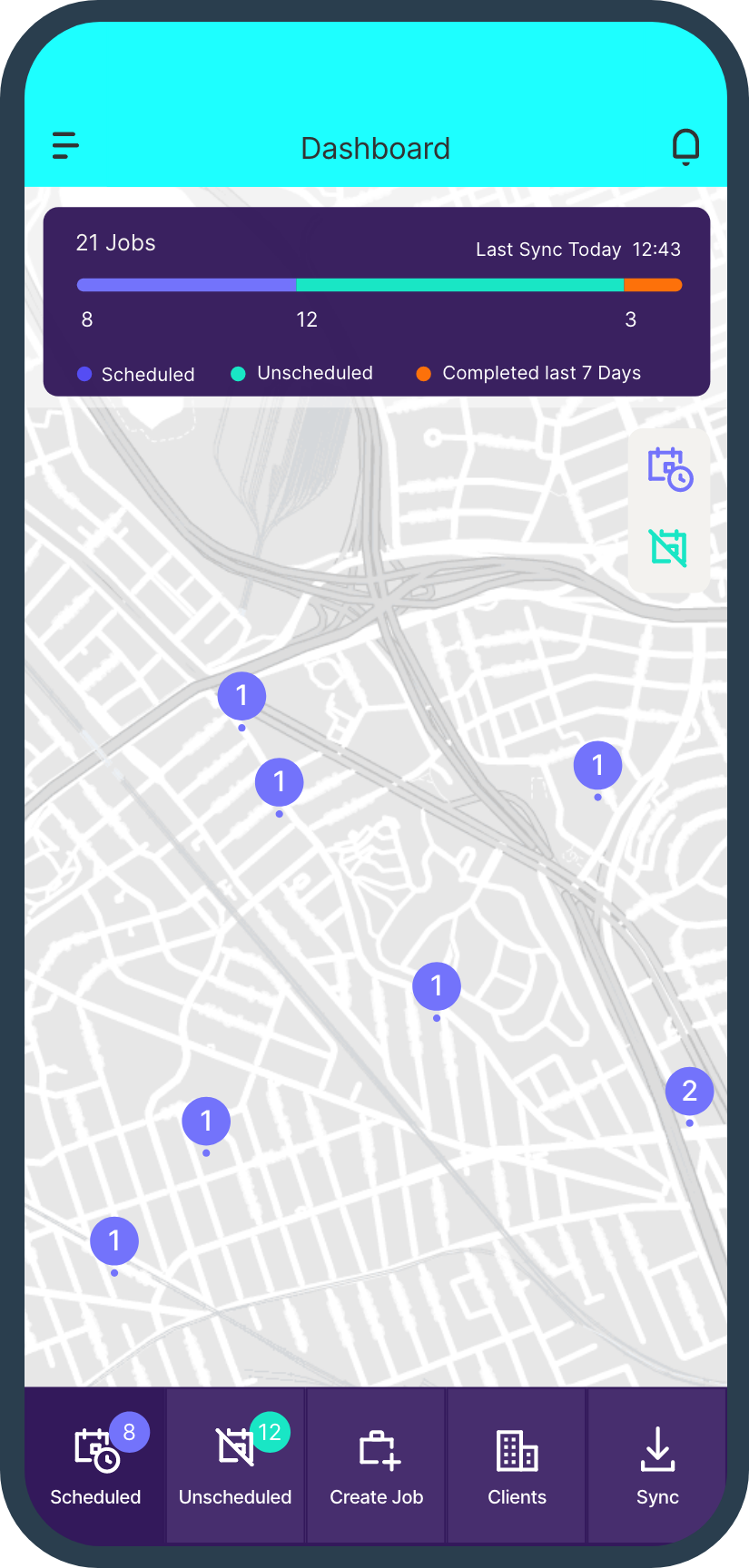

Try it for Free

14 Day Trial. No Credit Card. No Obligation.

Klipboard is the future of field service and can improve the way you work regardless of the size of your business. If you manage people in the field and you want to offer your clients a great experience, try our 14-day free trial today.