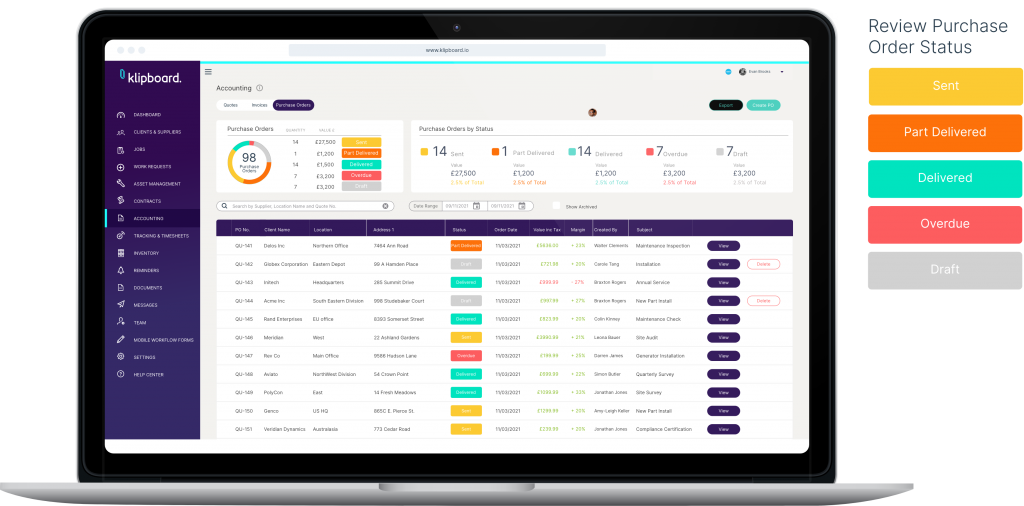

Raise Purchase Orders & replenish stock.

For reactive and planned jobs, you can easily create Purchase Orders and email directly from Klipboard to your suppliers. Track the progress of Purchase Orders through to delivery and the associated costs. Once delivered, allocate purchases to inventory stock counts along with the costs and items being added to the job.

Klipboard will mark up the cost of the purchased items on the job using the selling rates when creating the invoice. Purchase Orders are marked as 'awaiting delivery' or 'overdue' so you can quickly see which are still open and to chase suppliers for deliveries therefore ensuring your jobs that are awaiting items are not delayed.

Convert Quote line items to Supplier Purchase Orders

When you create a quote on Klipboard, you can add the inventory items to the quote from a library. The inventory library contains the preferred supplier and the cost price of the item. When a Quote has been accepted by your client, they can then be easily converted to Purchase Orders. We work out what line items on a Quote are associated with the preferred supplier and copy those into a new Purchase Order - saving you admin time and ensuring you can get to ordering the required items for that winning Quote and job efficiently.

Try it for Free

14 Day Trial. No Credit Card. No Obligation.

Klipboard is the future of field service and can improve the way you work regardless of the size of your business. If you manage people in the field and you want to offer your clients a great experience, try our 14-day free trial today.

Budget with confidence.

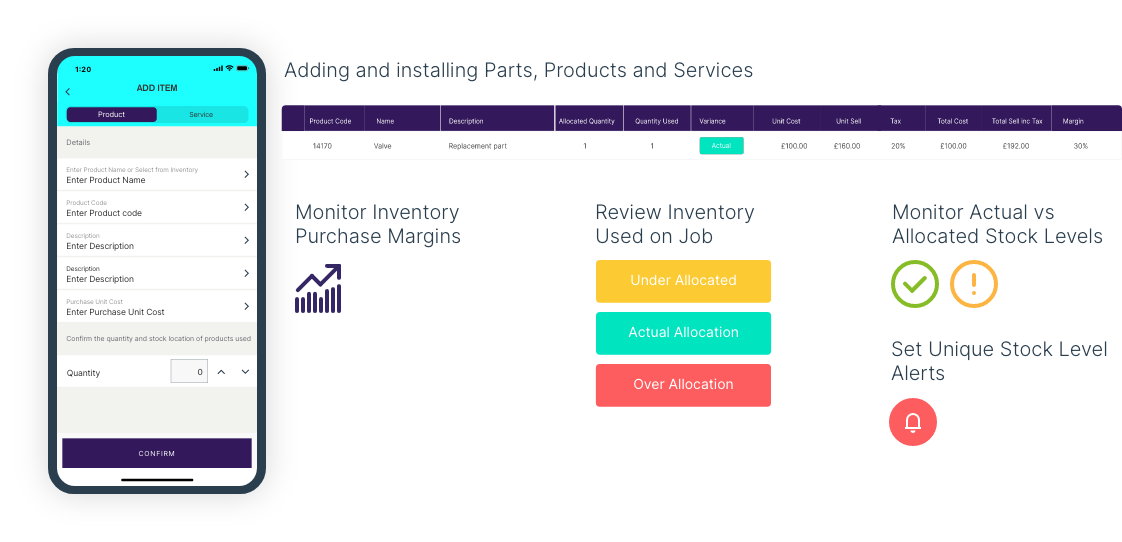

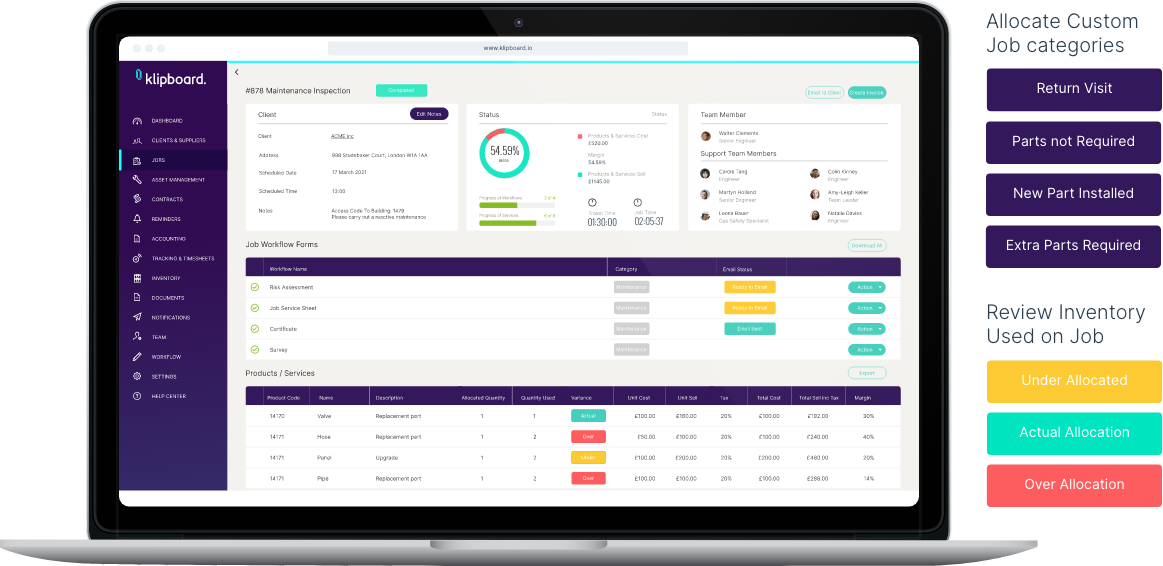

Easily track the products, parts, materials used and labour ensuring job budgets are adhered. Klipboard provides a comprehensive job overview dashboard for each customer job allowing for visibility of job costs, margins, inventory allocated and used.

Multiple inventory stock locations? No problem!

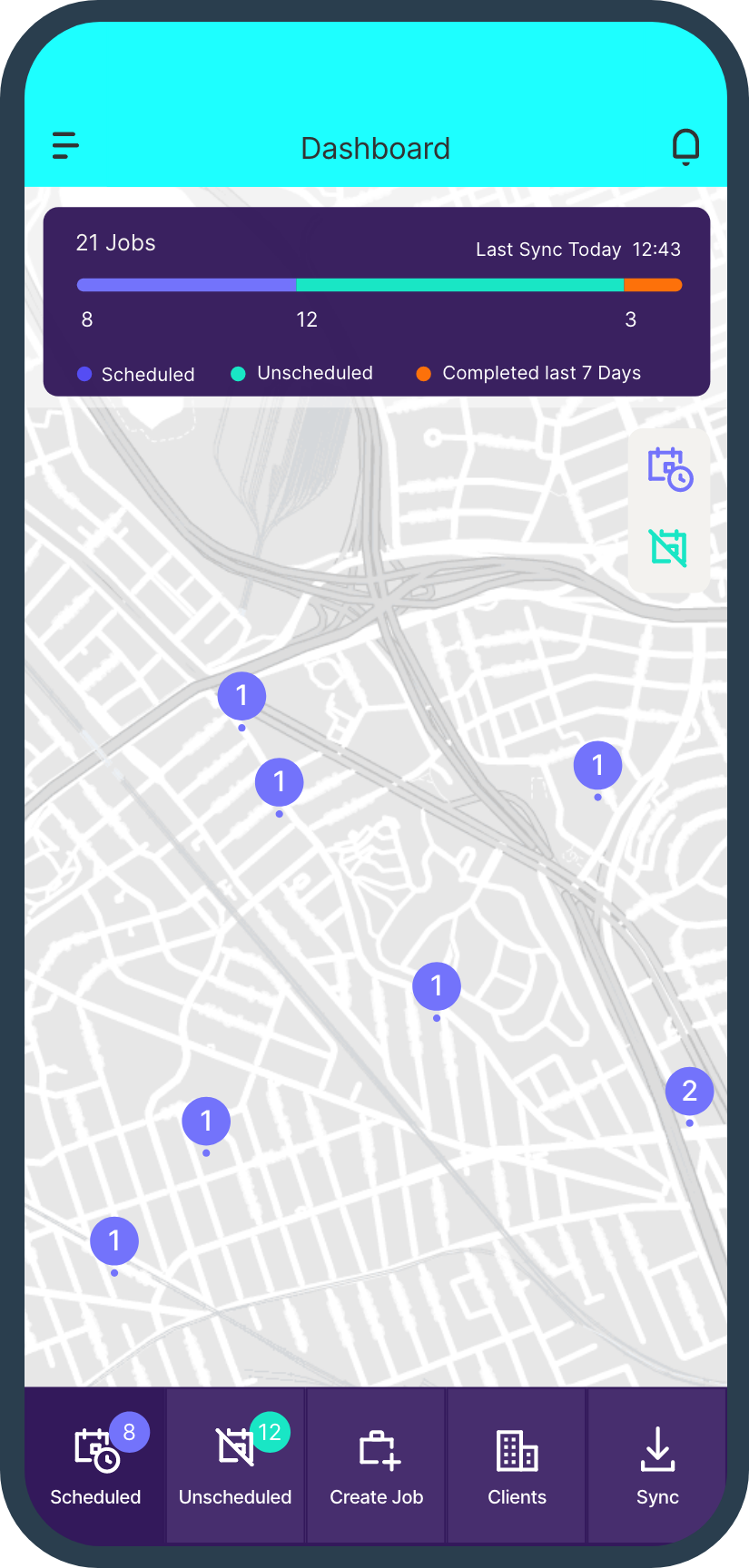

Klipboard's comprehensive Inventory Management features enables you to create multiple stock locations, such as warehouses, vans or regional depots. Each location displays a real time stock count along with the ability to set the minimum hold quantity therefore ensuring you are alerted and can re-order accordingly. Inventory can be easily transferred between locations ensuring it is where it needs to be for the relevant job.

Instant visibility of inventory allocated to jobs in the field

When a job has been assigned and synced to the mobile app, it will display any inventory stock allocated to that job therefore ensuring the team member knows what products, parts or materials is required / allocated for the job. Using the Klipboard mobile app, team members can easily confirm the products, parts or materials used on the job and Klipboard will auto-deduct the items from the relevant inventory stock location.

For any ad-hoc purchases in the field, these can be easily added therefore updating the office on any additional costs on the job and therefore billed to the customer if required. A permission option on the Klipboard web dashboard can be enabled to hide or show any financial information displayed for the inventory allocated to the job.