Planned Preventative Maintenance (PPM) schedules for biomedical equipment maintenance is the process of ensuring the continued functionality of sophisticated medical equipment. This is achieved by carrying out inspections or servicing on a planned schedule.

In this article, we cover:

- Why Planned Preventative Maintenance schedules are needed for medical equipment servicing

- The benefit of medical devices and equipment on PPM schedules for your clients

- How PPM schedules are carried out by Biomedical Equipment Technicians

- Why Biomedical Equipment Technicians use software for planned preventative maintenance schedules

- How Medical Servicing companies anticipate the needs of their healthcare clients

- How one of the largest US biomedical servicing companies manages their PPM schedules

Why PPM Schedules are needed for Medical Equipment servicing

The quality of the healthcare offered by your clients is directly linked to the effectiveness of the equipment being used. Should the performance of the medical equipment drop, it can have a significant effect on the quality of a patient’s treatment.

Planned Preventative Maintenance schedules reduce the downtime of equipment by spotting potential failures early. Continued Maintenance Contracts are made easier to manage by using PPM schedules to plan out the frequency of servicing of medical equipment.

A report by McKinsey & Company, found that regular planned maintenance of medical devices through a PPM schedule minimises warranty costs and avoids the need for expensive urgent service visits. You can see more on that report here.

“As a result of PPM schedules the aggregate rate of emergency field service calls and visits fell by more than 20 per cent”

McKinsey & Company

How your customer benefits from have their Medical Devices and Equipment on PPM schedules

The long-term benefits of running PPM schedules on medical equipment are extensive. However, some customers may feel they only need your maintenance services when there’s a problem. This is a costly way of operating, and it’s in your customers’ best interests to think more long-term. Here are some key examples of how PPM schedules can help the medical industry:

Extended lifecycles

When medical equipment breaks down, it takes a toll on the machinery. With regular routine inspections and small repairs and part replacements carried out with a PPM schedule, the lifecycle of medical equipment can be extended, and your customers will achieve a better ROI on their devices.

Fewer call-out charges

Every unexpected breakdown is costly, not just because your customers cannot offer a service or provide the patient care they strive for but also because they have to incur call-out charges from service partners. The reduction in call-out charges alone should be enough to encourage your customers to adopt a maintenance plan based on preventative maintenance schedules.

Predictable maintenance schedules

It’s much easier to find time in both your schedule and your customers when there is a predictable pattern of when the PPM jobs are booked. Your customer won’t have to wait longer for their equipment to be serviced when all scheduled dates are in the diary.

Fewer business disruptions

Anytime a piece of medical equipment fails, it is disruptive. Asset downtime can seriously impede a patient’s care and create a very poor experience. Your customers hold the quality of their care above everything else and that’s why it’s important to maintain optimum performance from their medical devices.

Increased first-time fix rate

One of the key issues faced by Medical Equipment Servicing businesses is stock and part availability. Current Global Supply Chain issues can affect your ability to source replacement parts quickly. By adopting a PPM schedule for medical equipment maintenance, part usage will be more predictable, and you’ll quickly spot if you need to order new parts. With access to the parts and inventory you need to complete the service, your First Time Fix Rate will improve, and your customer won’t experience extended periods of asset downtime.

How are PPM schedules in Biomedical carried out by Biomedical Equipment Technicians?

The overall goal of Biomedical Equipment Technicians (BMET) is to keep their client’s medical equipment operational and avoid unexpected call-outs, which can disrupt a patient’s treatment.

Replacing or repairing parts before a breakdown occurs will ensure the equipment has a longer operational lifecycle and reduce the negative impact of equipment downtime. The time between each service or inspection will depend on the equipment.

Having well-structured PPM schedules can be highly beneficial to the client and the Biomedical Servicing Company. The client will avoid the negative impact equipment downtime has on their business, and the servicing company can rely on reliable, predictable cash flow.

Why Biomedical Equipment Technicians (BMET) use software for PPM schedules

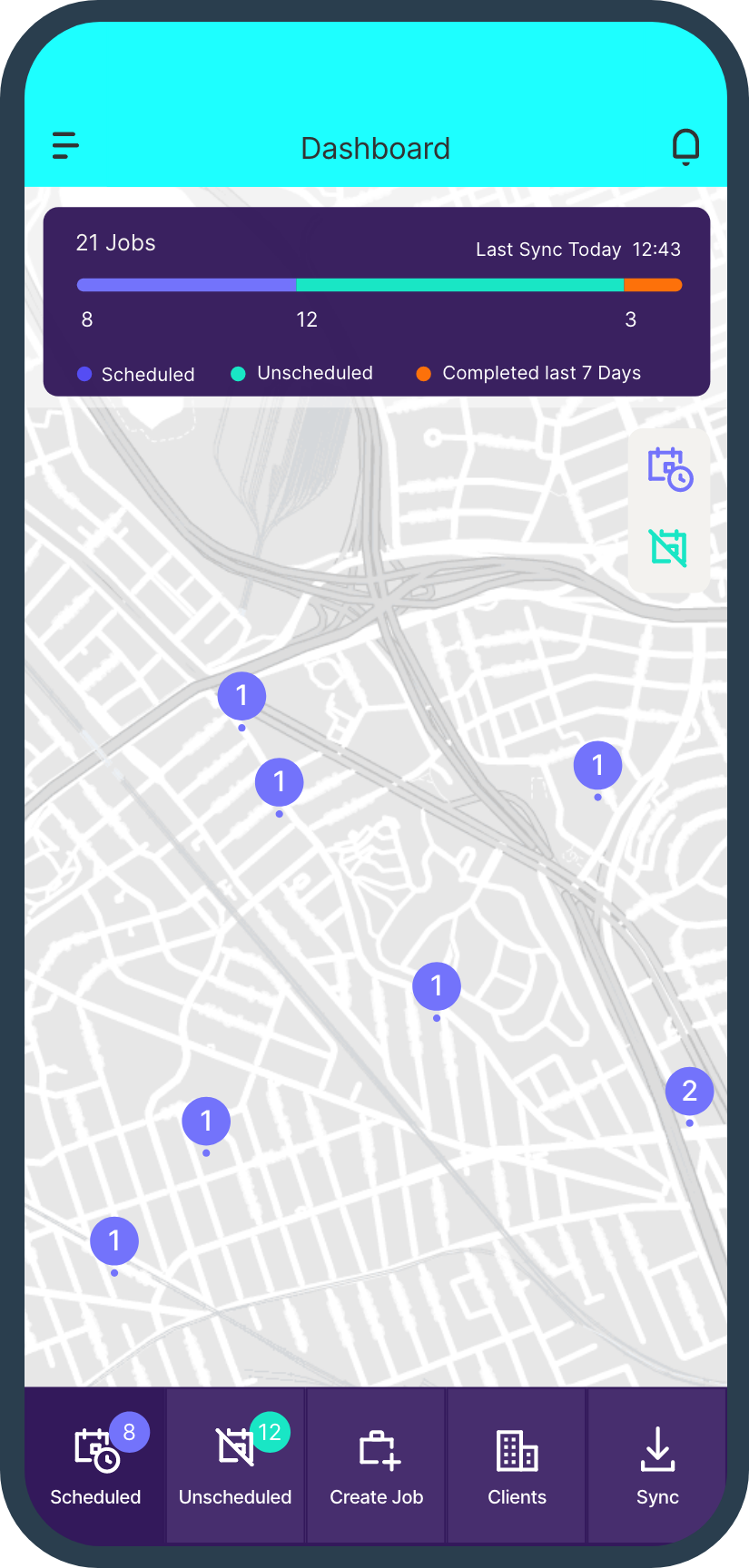

Most Biomedical Equipment Technicians (BMETs) rely on software to plan out their PPM schedules, and Job Management Software gives them access to documentation and notes on the equipment.

Photos can be taken on site and uploaded to the asset which can help identify repeated failure points and give the technician what they need to make an informed decision on whether to repair or replace.

Managers or Team Schedulers at Biomedical Equipment Servicing companies will plan their next few weeks and months, ensuring they rotate through the planned maintenance schedules for their clients.

How Medical Servicing companies anticipate the needs of their healthcare clients

To grow and develop the relationships they have with their clients, Healthcare and Medical equipment servicing companies use the data they collect on-site to make better decisions.

Replacing equipment can be a costly affair for their clients but with data to support their proposal, it’s a lot easier to advise customers on the long-term benefits of replacing equipment rather than continuing with ongoing repairs.

“To be able to see very easily what we had to do previously for that particular piece of equipment is so valuable.”

Sarah Betteley, Deva Medical

Every inspection or service they complete provides more information that Medical Equipment Servicing businesses can use to track trends in equipment faults.

The data that Sarah’s team collects on-site using Klipboard, helps Deva Medical make better, more informed decisions regarding the maintenance of their clients’ Healthcare equipment. Learn more.

How one of the largest biomedical servicing companies in the US manages their PPM schedules

Land Sea and Sky, manage the recurring PPM schedules for hospitals and clinics and are one of the largest biomedical equipment maintenance businesses in the US to offer this service.

Owner Chris Hysinger and his team are expected to monitor how often each microscope needs to be serviced and manage the PPM schedules to ensure their client meets compliance regulations.

This presents a huge challenge for them, m. Mainly because they could be dealing with different people at the hospitals and those people can’t be expected to know the service expiry date for the equipment; it’s down to Land Sea and Sky.

Chris says: “Previously, it was a huge task and we were regularly called up by the client to say ‘We’ve got this many microscopes needing servicing and they have to be done by Friday because that’s when they expire’.”

Using PPM schedules managed in Klipboard’s Field Service Software, Chris is able to have a complete picture of the work that needs completing and not get caught out by unexpected calls from the client.

Here’s a video of Chris explaining how that works:

“Klipboard has revolutionized our ability to track each asset service”

Chris Hysinger, Land Sea and Sky

They are now able to track the service history for each asset by creating a record of it in Klipboard, adding serial numbers or asset tags and giving their team full visibility of the service dates and service history.

Land Sea and Sky are now able to be proactive and contact their clients ahead of time to schedule the service.

PPM Schedules in medical servicing are simplified by using Field Service Management Software from Klipboard

Klipboard’s Job Management Software helps Field Service Engineers schedule medical equipment servicing and improve the overall quality of the service offered to healthcare clients.

Take a look at this short video to see how easily you can create PPM schedules for a client:

With Klipboard you’re able to quickly find your client’s details and raise a job. Previously you would need to book a job onto your CRM system and then separately schedule more service dates into a calendar. Without Klipboard you would have further admin to do by sending the assigned technician documentation and details on the asset they are servicing. Learn more.

You may also be interested in… “Why Self-service portals are expected by Medical Customers”

A recently published report found that 88% of customers expect a brand or business to offer an online self-service portal. You can read more about that and how it can help you improve the service you offer to your customers on PPM schedules by reading this article.

Visit the Medical & Healthcare Maintenance page for further information on how Klipboard can assist in medical field service management.