A call out can affect your whole schedule. One moment you’ve got your team booked exactly where they need to be, then suddenly a valve breaks on a water softening installation and your customer needs you immediately.

Here’s how successful Water Treatment & Hygiene Specialists handle call outs and the changes you could make today to reduce the impact they have on your team’s productivity.

In this article you’ll find out:

- Why call outs create a problem and an opportunity

- What are the common reasons Water Treatment Specialists are called out for a repair

- How successful Water Treatment & Hygiene Specialists manage call outs

- How Rochester Midland Corporation manage to respond faster to their customer’s requests

Why call outs create both a problem and an opportunity for Water Treatment & Hygiene Specialists

Many Water Treatment Specialists operate their service business on planned preventative maintenance (PPM) schedules.

There are two key reasons why Water Treatment Specialists use PPM schedules:

- The equipment they service often has to be regularly tested for contaminants such as Legionella and other bacteria to meet compliance.

- General wear and tear of water treatment softeners, tanks and filtration systems is significant. Keeping them in peak condition requires engineers to service them regularly.

How call outs affect a PPM schedule is quite simple. You had a plan to visit Customer A but Customer B requires immediate assistance and your team is already on a job.

Customer A may have to wait, or be seen later in the week.

If you’ve correctly managed the schedule of maintenance for your customers then it’s unlikely that a single instance of a job will impede your ability to ensure they meet compliance.

You will however, have to inform them promptly and be able to quickly re-schedule that job.

Call outs can be an opportunity to impress

It’s easy to think of a call out job as disruptive and an inconvenience. However, if managed promptly it can be an opportunity to impress your customer.

If they are calling you out for an emergency visit, this most likely means they have an urgent need for help. Providing that assistance in a calm, controlled and reassuring manner only enforces a positive and professional impression of your business.

Prompt communication, swift dispatching of your team and immediate resolution will make you stand out as a key service partner.

What are the typical reasons Water Treatment Specialists are called out?

Here’s a few common reasons why Water Treatment Specialists are called out to a sudden and unexpected repair.

Also, we’ve shared some advice you can give to your customer to avoid the situation recurring.

Physical Damage

Careless use of equipment such as forklift trucks, vans or swinging loads from cranes for example, can cause physical harm to water treatment assets.

Advice you can give to your customers: Remind them it’s the responsibility of their employees to operate equipment with care around their water treatment assets. It’s a legal requirement in many cases too, such as not operating machinery with a raised bucket or forks.

Ensure the correct distances are outlined between moving machinery and the water treatment assets. In the instance of physical damage to the equipment the customer should carry out an assessment of the work area to avoid future issues.

Poor maintenance

Without a Planned Preventative Maintenance (PPM) schedule your client’s assets could be seriously damaged and the financial losses could be significant.

Advice you can give to your customers: Your customers’ assets need to be on a PPM schedule to help ensure their equipment runs efficiently, incurs fewer breakdowns and has a longer life cycle.

Those costs will certainly out-weigh the cost of call out charges and the financial impact that faulty equipment can have on their business.

You will need to ensure you have the correct processes in place to carry out PPM schedules for your customers. To do this correctly you’ll need to ensure you have smart job scheduling tools, automated service reminders and asset management tools.

You can read more on that here: What is a PPM schedule

Corrosion

It’s estimated that the global cost of corrosion is in the region of $2.5 trillion.

In the IMPACT study by NACE International, they found that implementing corrosion prevention best practices could result in global savings of around 30% of the cost of damage.

If your customer needs your assistance on a call out and the root cause is corrosion, that’s a significant issue and this could result in a costly repair or in the worst cases a complete replacement of the asset.

Advice you can give to your customers: Corrosion is caused by a build up of electro-chemical reactions. It doesn’t happen overnight, it’s the consequence of an ongoing exposure to an oxide or compound.

With regularly scheduled servicing this can be quickly identified and treated, reducing the risk of a breakdown or fault.

Human Error

While poor installation, design or substandard repairs can create breakdowns and to some extent are caused by human error. Sometimes you’ll be called out to repair because of improper use of the equipment.

- Lack of training

- Under filling or Over filling

- Operational error

- Allowing faulty equipment to go un-serviced

Advice you can give to your customers: Be clear with your customer why the fault occurred will help reduce future issues. Human error mostly occurs when there’s a lack of concern given to training and accountability.

A training programme reminding their employees of the implications of improper use will be cheaper than callout charges or worse still, replacing damaged equipment.

Erosion

This is caused internally by a constant and excessive passing of fluids which cause a cavity. Changes in the flow direction or the presence of foreign particles can also cause erosion.

Externally, erosion can be caused by salt, sand or wind.

Advice you can give to your customers: Erosion can be controlled by ensuring the right materials, coatings and coverings are used on water treatment equipment.

Similar to corrosion this rarely happens over a short period of time and can be easily identified by carrying out PPM schedules.

Defective parts

If the equipment has been issued with incorrect parts in a recent repair then the unsuitable replacement might cause a breakdown.

If you’re servicing water treatment equipment for the first time because your business wasn’t previously responsible for it you could discover improper parts being used. Or your team could identify the use of a recalled or defective part.

Advice you can give to your customers: Your service business is now responsible for the equipment, so the first piece of advice is something you need to give to your own team – be vigilant.

Make sure they correctly record the condition of the parts during planned maintenance visits.

Encourage them to document and take pictures of parts they believe to be incorrectly installed or known to be defective. Using photo evidence included in reports collected on site with mobile forms will help you build a case for replacing the part.

To your client it’s worth stressing that replacing these parts now will avoid difficult situations later down the line should the part fail.

How successful Water Treatment Specialists handle call outs

There are several stages of handling a call out, here’s how successful Water Treatment Specialists master them.

1. They manage in-bound communication effectively

The most important thing to manage straight away is your client’s concern. Put them in a calm state of mind by communicating with them quickly and effectively.

It’s imperative that your support team gather the details of the issue quickly and professionally.

Your team will need to be able to quickly access the client data either through your CRM system or Job Management Software. This reassures your customer that you understand their situation and can resolve it quickly.

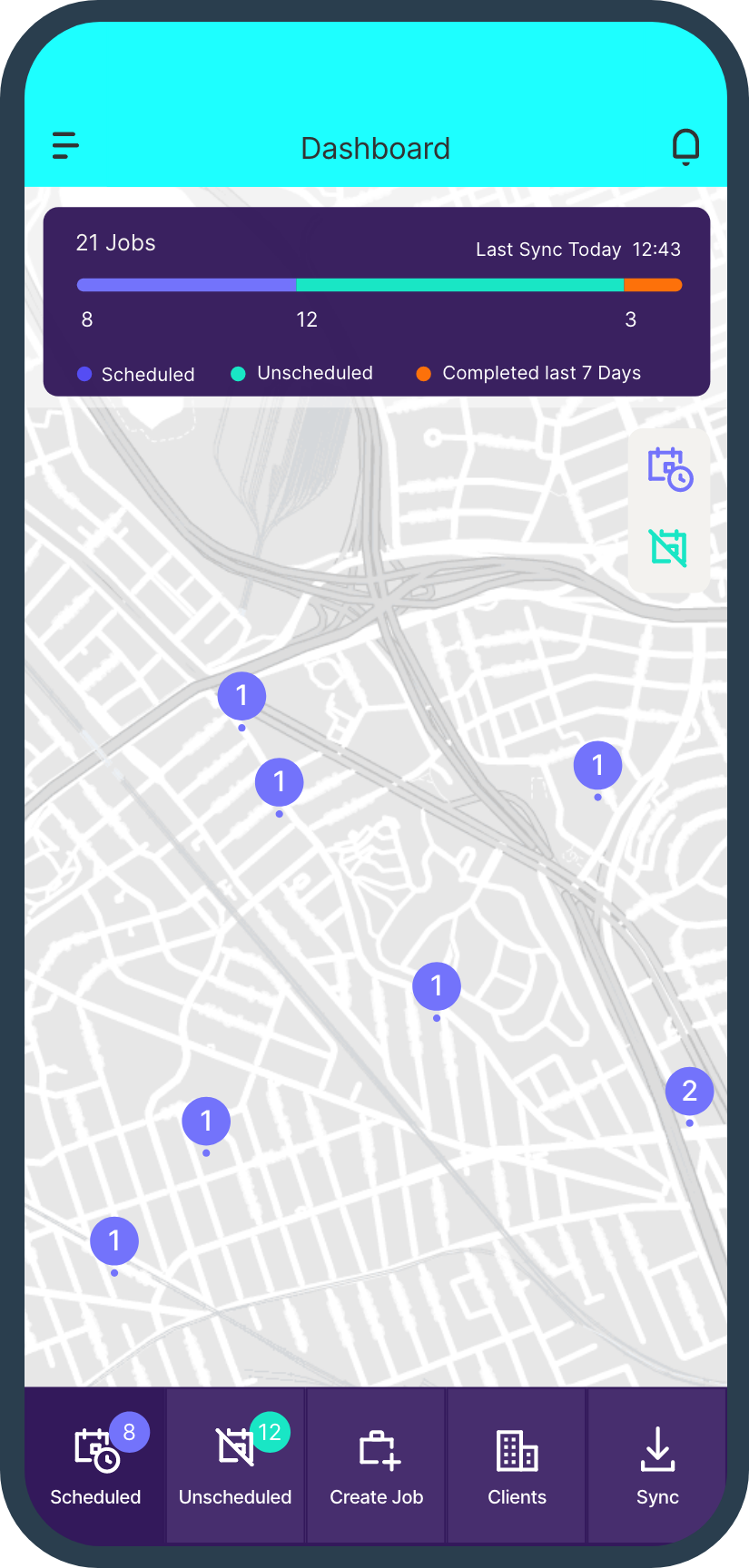

2. They have complete visibility of their team’s schedule

How do you expect to send the right person to the call out if you don’t know where everyone is working?

Calling around to see who might be available is time consuming and disruptive.

Using a simple and clear job scheduling and dispatch tool you’re able to see where everyone is and who the best engineer is for the job. Using Emails and Calendars can be ineffective if the schedule has changed and not been updated properly.

Successful Water Treatment Specialists use cloud based Job Management Software to get a real time picture of where their team is and who might be available.

3. They have built-in flexibility in their processes

To get your team to attend the call out you’ll need a certain degree of flexibility in your processes.

You’ll need to be able to change your schedule and send an engineer or team of engineers to the job rather than what they had originally been assigned to.

One of the biggest issues a call out creates is something that’s often overlooked. The instability this causes for your engineers.

Having a system in place that notifies them of a change in the schedule and gives them detailed information of the new job helps make them feel informed and considered.

4. Real time notification are used to confirm bookings

We are living in an ‘on-demand’ era and your customer expects to be notified of the status of their job. When they require a Water Treatment Specialist to quickly come and resolve an issue they will expect SMS or Email confirmation the job is booked.

This is reassuring for the customer and aligns with their expectations of better visibility of what’s happening from the services they pay for.

Whether it’s booking a taxi or ordering a meal, customers expect ‘Uber-like’ notifications of what’s happening, who is arriving and when they are likely to get there.

For more on how you can create an ‘Uber-like’ experience for your customers check out this article: Read more

5. They have real time visibility of their client’s assets to avoid confusion

Your engineer won’t want to search through a great number of emails or attachments to find details of the water treatment asset they have been called out to repair.

Successful Water Treatment Specialists, use cloud based Job Management Software with asset management tools to share that information with their field team on the go.

A quick sync of their app and they will have all the documents, service history and technical drawings they might need.

The time it would take for your team back in the office to collect all the information your water treatment engineer needs for the call out could be considerable, without cloud based job management software.

When your engineers have everything they need quickly it empowers them to resolve the issue faster.

6. They use follow up emails to encourage positive reviews of their water treatment business

What makes some Water Treatment businesses more successful?

They capital on the good will of providing a fast and professional service by following up with an email after the job for feedback or a review.

These reviews are used in marketing, social media and could potentially be the reason why they secured their next job.

If you’re interested in the impact Google Reviews have on your service business check out this article. Read more.

How Rochester Midland uses the Klipboard app to respond faster to their customer’s requests

Rochester Midland Corporation had previously been scheduling their water treatment jobs through a manual process and used paper based methods for collecting site report information.

This cost them a lot of time and usually the process took around 2.5 hours per day to complete each job.

To keep up with the demands of their customer, reduce the time spent on admin and provide client reports faster, they switched to Job Management Software from Klipboard.

“Its fantastic software and has made completing jobs in the field a lot easier. Klipboard has helped us with meeting compliance and allowed us to provide client reports faster” – Stephen Biggs, Operations Manager

Using Klipboard they have streamlined their business operation and the management of their field engineers.

Gone are the old ways of the past and they have ushered in a new, faster, more efficient way of scheduling jobs, dispatching them to their team and responding quicker to customer call outs by using the Klipboard Mobile App.

Over the first 6 months of using Klipboard they saved around 350 hours.

This gives their team more time to handle customer requests, carry out planned maintenance schedules and takes the pressure off their field teams by giving them a more manageable schedule.

You can read more about how Rochester Midland Corporation use Klipboard to manage their water treatment jobs. Click here.