Field Service business will continue to be affected by ongoing Global Supply Chain issues. Here’s why and the changes you can make today to limit the impact it will have on your business.

U.S – China Trade disputes, Brexit, Covid-19 and many other factors are causing disruptions to the Global Supply Chain. This affects your ability to secure spare parts, replacement machinery and could lead to longer downtime for your customers’ assets.

A recent report suggested that 94% of Fortune 1000 companies are experiencing supply chain disruptions. If you are finding it hard to secure parts to make your repairs, you’re not alone.

How disruptions to supply chains affects Field Service businesses

The supply of parts, materials and equipment is vital for the engineering and service maintenance sectors. They rely on predictable availability of parts to carry out the repairs and services of their customers’ assets.

The compounding factors of international disputes and navigating complex legislation from Brexit, is creating a bottleneck which will be felt most by small to medium sized businesses.

The next time you order a part that would have previously taken a week or so to come into stock, might take weeks or months next time.

This only highlights the importance of accurate forecasting of the parts you’ll need to order and having greater visibility of the jobs you’ve got coming up over the next weeks and months.

Part availability will be affected by supply chain issues

One of the biggest pain points being felt by service businesses is the availability of parts. This is particularly true for industries that supply equipment that is manufactured overseas.

Only 12% of chips are produced in the United States. This has meant chipsets, circuit boards and semiconductors are particularly difficult to obtain.

Almost every Field Service business will have to consider where they secure parts from and how often they order them.

Any delays in getting assets operational because of part availability issues, will greatly affect their customers ability to keep their equipment running. Your ability to complete your customers’ jobs is directly affected by your ability to order parts when you need them.

Almost every Field Service sector will need to be more proactive with their Inventory Management

Most mechanical and electrical equipment uses chipsets and the increased usage of IoT devices (Internet of Things) is only increasing the scarcity of these parts.

The Bio-Medical and Healthcare industry is putting the chip shortage in the spotlight. Life-saving technology such as MRI machines, blood monitors and scanning equipment require many parts that are in short supply.

The Telecommunication Industry is another example of a business, completely reliant on two things:

- Chipsets and Semiconductors to build new equipment

- Continued and predictable operational effectiveness

Without the parts available Telecommunication Service Engineers will struggle to make the repairs needed to keep this equipment working and meet SLAs.

Almost every industry in Field Service will be affected by chip shortages. Service businesses will need to be proactive in their Inventory management and monitor usage closely, so they don’t disappoint their customers.

It’s not just chip sets affected by Global Supply Chain issues

Even the most basic of common piping and plastic moulding can come from overseas. The issues created by the disruption of the global supply chain are felt beyond industries operating at the cutting edge of tech.

Plastics in particular are suffering from supply chain issues.

The materials are coming back into production but it’s the availability of labor that is causing concern. Since June 2020 the labor participation rate has remained around 62%, meaning that even with the materials, the products aren’t coming off the line fast enough.

The construction industry is being hit from two sides, the rising cost of materials and labour shortages can make every project feel like it’s behind schedule and running over on costs before it’s even started.

The cost of timber and steel has doubled, reducing the profitability of each job or leading to increased prices that have to passed onto the customer.

Even multinational businesses are being affected by Global Supply Chain issues

Luxury car manufacturer Porsche, owned by Volkswagen, recently put a stop to the production of a line of their vehicles because of the inability to secure a simple cable tie.

7% of all automotive electrical wire ties used in the world are manufactured in Ukraine, which is in conflict with Russia.

The sudden and unexpected invasion of Ukraine has made VW “partly stop all model lines” and is an example of the need to be better prepared with multiple sources for parts.

Obviously, VW is an exceptionally large and complex company. However, it shows that even the most well managed businesses aren’t immune to the difficulties supply chain disruption can create.

Your First Time Fix Rates could be impacted by Global Supply Chain issues

To run an efficient and profitable Field Service business your First Time Fix Rate needs to be better than good. A First Time Fix Rate (FTFR) is the frequency at which an engineer is able to complete a repair at the first time of asking.

Successful Field Service businesses that have an excellent FTFR benefit from:

- Increased Customer Satisfaction

- Improved Engineering Competency

- Efficient Asset Management

- Reduced Downtime frequency of Assets

Disruption to the Global Supply Chain is affecting Field Service businesses by impeding their ability to achieve a high FTFR because of the scarcity of parts needed to complete their repairs.

7 ways to lessen the impact of Supply Chain disruptions for your customers

There are ways to mitigate the impact supply chain disruptions can have on your customers and your ability to complete each job.

1. Improve visibility of your stock

Use software to monitor your inventory and get a real time view of what’s being used. It’s important to know more than just how many of an item you have, you need to know its location, even down to what van it’s in.

2. Create stock buffers

Have a system in place that will inform you when you’re getting low on a particular part or piece of machinery. You may have to adjust the minimum quantities of these items you have in stock, if you become aware they are getting increasingly difficult to obtain.

3. Communicate effectively with your team and suppliers

Having a good relationship with your supplier can be a game changer during periods where parts become more difficult to secure. Your Field Team will also help you identify parts that you might need to order in.

4. Don’t be overly reliant on one supplier

Diversify where you get your parts. A breakdown in one provider’s supply chain might not affect all providers. It’s possible you’ve agreed terms with a supplier and that’s a great way to secure cost effective purchasing. However, you need to have a good relationship with a few different suppliers to mitigate supply chain issues.

5. Nearshoring

Nearshoring simply means bringing everything closer to home. When you are reliant on overseas suppliers, you also extend your lead times on getting the parts. By nearshoring, you are securing parts and equipment closer to home. It might mean their pricing terms aren’t as favourable but there’s a balance you’ll need to find between expense and availability.

6. Control your customers’ expectations

If you manage your customers’ assets on a Planned Preventative Maintenance (PPM) schedule then it shouldn’t come as a shock to you that you need to service a particular piece of equipment, so you should have the parts. However, if you are called out to repair an unexpected breakdown, set realistic expectations with your customers.

Make sure you can check your Inventory in real time and give them advice based on what your data says.

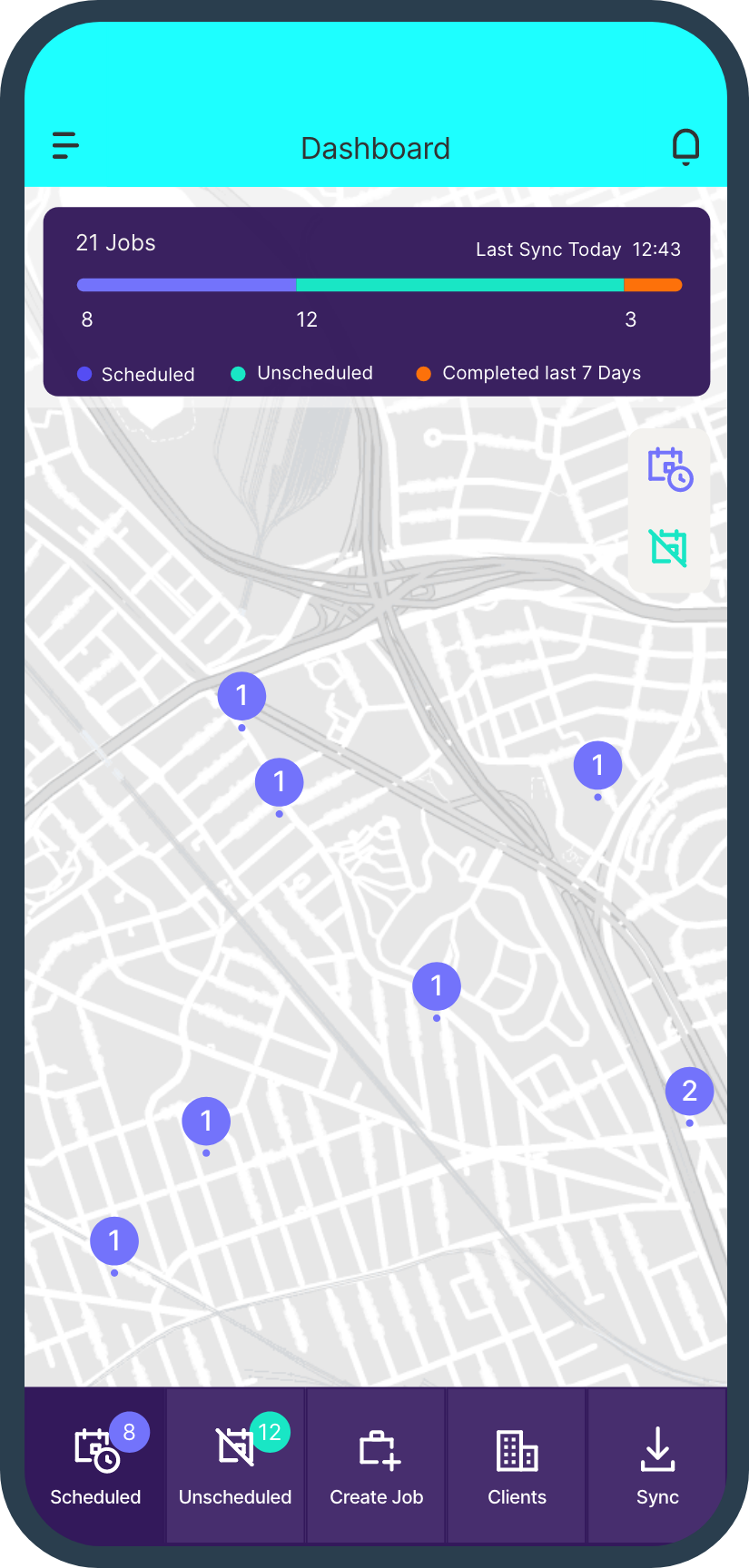

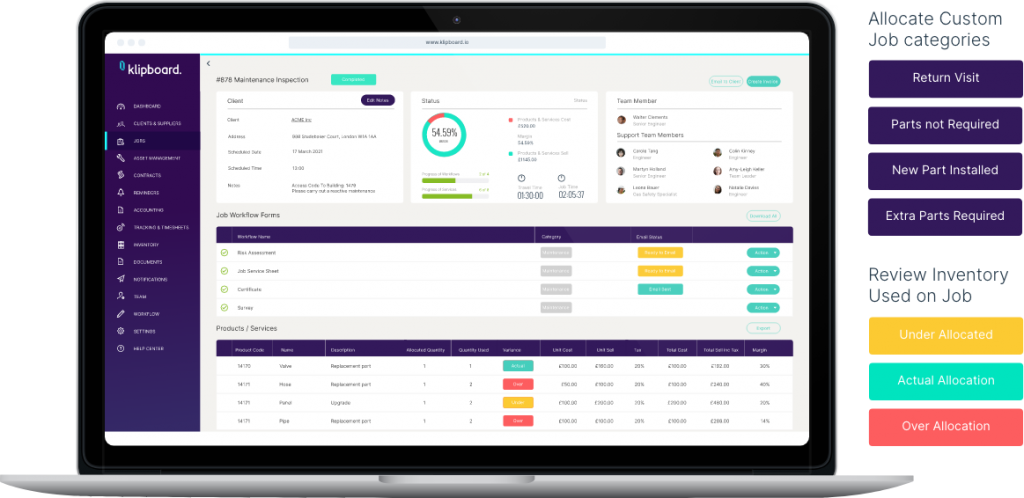

7. Start using Job Management Software

If you want to limit the impact disruptions to the Global Supply Chain has on your service business you need to improve your operational visibility.

All of the tips above require you to have a complete, top down view of your business and the easiest way to do that is by using Job Management Software.

Klipboard helps you streamline your job scheduling, quoting and invoicing. One of the biggest benefits you’ll feel at the moment is the real time view you’ll have of your parts and customers’ asset maintenance schedule.

Being able to clearly see what services you have coming up and the parts you’ll need for those services will greatly improve your ability to meet your customers expectations.

How the Global Supply Chain issues will change the future of Field Service

Field Service Management Software has already provided a present day solution to having a real time view of your Job Schedules, Field Service Finances and Inventory.

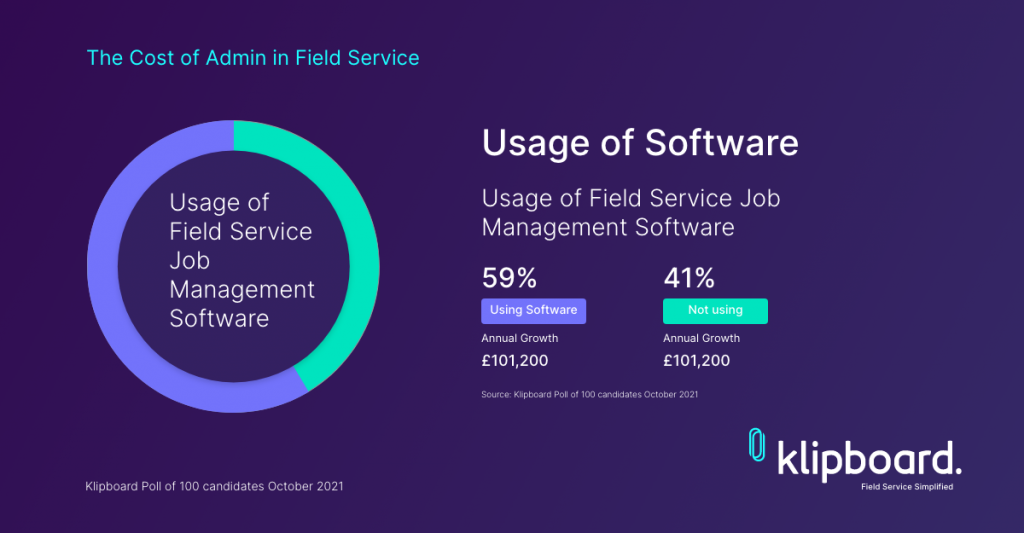

41% of Field Service businesses haven’t adopted Field Service Job Management Software. The industry is adjusting to modernisation, moving away from spreadsheets, emails and paper based job forms.

The future of field service will introduce the connection of devices in the field with the office. IoT (Internet of Things) will allow devices to notify service partners of a potential breakdown or fault. This will allow device and inventory systems to communicate so parts can be ordered even before they are needed.

Necessity is the mother of invention.

The disruption of the Global Supply Chain isn’t going away anytime soon, best estimates suggest it could continue into 2023. A positive sign is that it is encouraging industries such as Field Service, Manufacturing and Logistics to be more creative in how they manage stock, cost jobs and forecast their profits.