Poor inventory management will affect your bottom line and by ignoring it you’ll be making a common mistake in field service management. The good news is improving your inventory management is easier than you would think.

There are some steps you can take to improve your inventory management and the backdrop of materials shortages, supply chain delays and the increased pressure from customers is making this vitally important.

The cost of poor inventory management

It’s your customers who feel the biggest impact of your poor inventory management.

When your team arrives on site presuming the right parts and equipment will be available to them it greatly reduces the chance of a First Time Fix. Getting your customers equipment up and running at the earliest opportunity has a huge impact on customer sentiment.

Entre-Prises Climbing Walls are specialist design, install and servicing providers to the leisure industry. They understand an extended period of downtime for their clients assets is very costly. For their customers the difference between having their equipment operational or not is paramount to them being able to safely operate their business and generate revenue.

Entre-Prises Climbing Walls use Klipboard to keep a full asset register for their customers and are easily able to view their inventory. They can quickly see at a glance what parts are available to them and when the assets were last serviced. This ensures their customers’ equipment remain compliant, operational and profitable.

They never miss a service and their team will always have what they need available to them.

You can read more about Entre-Prises Climbing Walls and their story here.

How improving your inventory management can increase your profits

To increase your profits you’ll need to utilise your Inventory Management effectively, here are some changes you can make to how you record your stock and make smarter decisions on order frequency. Following these tips with help you make a positive impact on your profit margins.

Minimise your storage costs

Over stocking of items takes up valuable space, ideally you want to use an economic order quantity – it sounds complicated but it really isn’t. You just need on hand exactly what you’ll use, so you’re not storing your parts longer than you need to.

Klipboard can help you keep track of your parts so you don’t over stock or hold onto parts you’re not regularly using. It doesn’t matter if you store your items in a small lock up, across various vehicles or you manage large scale warehouses. You can save money on storage fees when you store only what you need.

A big improvement you can make on you inventory process is moving away from spreadsheets and having a real time view of your parts, their location and their costs. Klipboard gives you that visibility in the office and the field. Learn more.

Reduce losses

Each part or product your business purchases is an investment. It’s already a loss until you’ve used it so you better make sure you use it. If a part goes missing and another needs to be order as a replacement that will cut into your profit margin.

Using an inventory management system mitigates this by having clear visibility of the stock and how it’s recorded through out your business. Everyone is clear that the stock is being monitored and to take care of these assets.

Job costing is simplified when you have a better understanding of the cost of parts and you’re not wasting money on items you aren’t going to use.

Sell more

If you’ve convinced your client they need to upgrade their current equipment for a more efficient model and reduce downtime they will be keen on purchasing from you. What they might not be keen on is the delay they have to experience because the equipment you thought you had isn’t in stock.

If they are patient they may choose to wait for you to receive the products, however the strains on the logistics and supply chain many are experiencing at the moment is likely to extend their wait.

Deva Medical use Klipboard to monitor the performance of the equipment they service for their medical customers. Because they have a full service history, service notes from the engineer and a record of the parts they use and how frequently, they can report back to their customer with recommendations for replacing equipment.

They offer added value to their service because they go the extra mile of not only making cost effective recommendations but use data and insight from Klipboard to back that up.

With correct inventory management you can sell what you have. You can plan ahead and order the products you anticipate you’ll need and advise your service and sales teams accordingly. You can keep your client’s assets running for longer and when the time comes to replace them you’re more likely able to do so.

Improving your inventory management will increase field service customer satisfaction

It’s very likely your customers are sympathetic to challenges you might face in getting new parts. That’s because it’s likely they are struggling to secure materials themselves. However, how long are they willing to wait and do they believe you’re managing your inventory effectively enough?

Downtime costs them money and good relationships with customers can be put under significant strain when your stock management process starts to effect their profits.

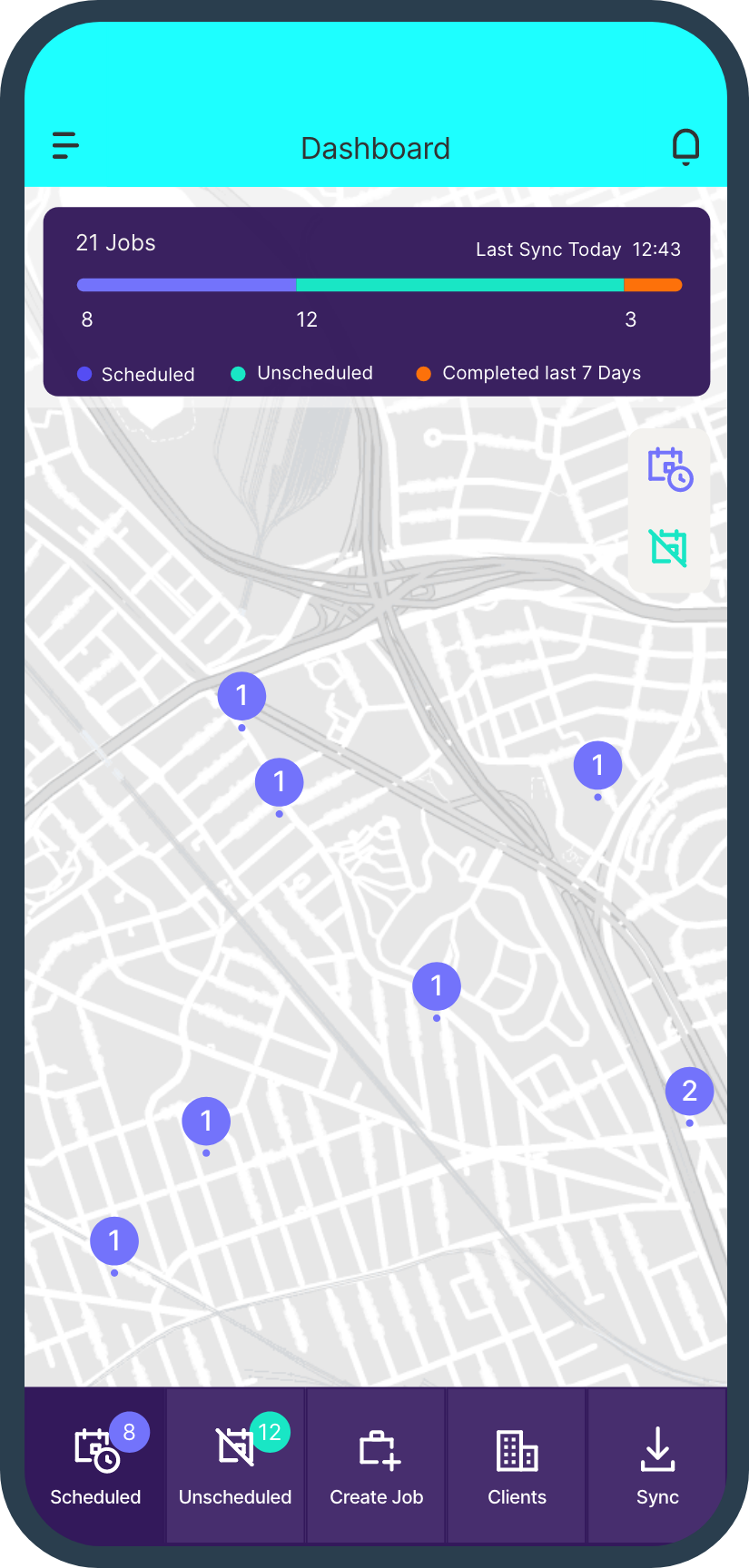

Klipboard helps create a clearer picture of what’s available and your engineers can advise your clients more accurately when they discuss orders and replaces on site by using the mobile app.

Field Service businesses who can provide insight into delivery expectations and more frequently have what they need in stock are much more likely to provide a service that keeps their customers assets operational.

Complete visibility means a happy customer

When your team are able to check the stock levels of parts and products on their Klipboard mobile app while they are on the job it will set expectations for your customer.

Being able to confirm you have the parts in stock and see exactly which location that part is held can make a big difference to your customer.

Improve loyalty

Speeding up the repair process will help improve your relationship with your customer and increase loyalty. Ultimately, your customer simply wants a service partner they can trust. By delivering a professional and reliable service you’re able to build trust and become a business partner rather than an expense.

Simplify Job Costing by having everything in one place

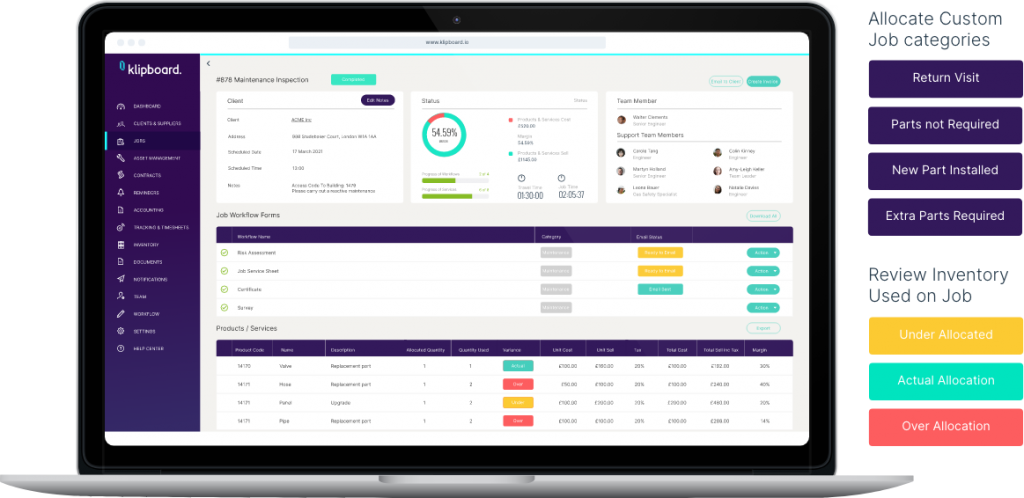

You’re able to closely monitor the total job costs and budget with confidence when your Job Management Software is also your Inventory Management tool.

You can easily track the products, materials, parts and even the labour costs ensure you know the true cost of each job.

Klipboard gives you a comprehensive job overview dashboard for each job allowing you to quickly view profit margins and inventory allocation.

You can even raise Purchase Orders and email directly from Klipboard to your suppliers then track the delivery progress and costs. Easily allocate the stock to locations once it’s been received and your team can see everything they have available in real-time.

Supply chain challenges require a new way of working

The backdrop of materials shortages, delays in supply chains and the increased pressures your customers are under will flow down to you. How you manage your inventory will be put under scrutiny is your system up to scratch?

Your customers will rely on you to have what they need when they need it or at least be confident you have a complete picture of what’s available so you can set expectations.

Perform better in the field and increase profits by improving your inventory management. You can do this by linking your job costing, servicing job management and inventory management in one platform.

Find out how Klipboard can help improve your inventory management and run a more profitable business by starting a FREE trial today. Learn more.