Hospitals and Healthcare facilities need to ensure all devices that are critical for the wellbeing of their patients are operating at peak performance and can be used safely. To ensure equipment operates as expected and meets compliance standards, servicing businesses use Medical Equipment Preventive Maintenance checklists.

Why Preventive Maintenance is important

The benefits of Preventive Maintenance are well documented. Many businesses ensure their assets are periodically inspected to ensure they operate at expected performance levels and meet compliance standards where required.

Advantages of PPM Schedules include:

- Less frequent downtime

- Fewer interruptions in service

- Extended Asset Lifecycle

- Improved performance

For medical and healthcare devices preventive maintenance has an added importance and that’s the quality of care and treatment to patients.

Read more: Why PPM Schedules are Vital for Medical Equipment Servicing

What is a Medical Equipment Preventive Maintenance Checklist?

Preventive Maintenance checklists set out the tasks a technician needs to carry out to complete a work order. These are required to ensure the correct inspections, checks, repairs and maintenance is completed to ensure equipment operates as expected or in some cases required to meet industry regulations and compliance standards.

Safety

One of the key reasons to complete Medical Equipment Preventive Maintenance checklists is to ensure the equipment or asset can be operated safely without putting the user or operator at risk.

Compliance

The accuracy and safety of assets is monitored to ensure they are calibrated or maintained to a level that meets industry standards. Many assets particularly Healthcare Devices and equipment that uses potentially harmful gasses must be safe to use so these checks ensure compliance.

Performance

The level of performance achieved by the asset is also important. Often equipment is directly linked to revenue so on top of safety of their operators, there is a direct link of Preventive maintenance and potential revenue.

Examples of Preventive Maintenance Checklists

Step by Step Preventive Maintenance Checklist

Many Assets have parts that have an expected life cycle. This is often measured in ‘hours of use’ and a Step by Step Preventive Maintenance Checklist allows service engineers to check the usage of the equipment and replace parts that have either failed or reached their maximum usage.

Step by Step checks are useful for ensuring vital checks are made and compliance related procedures are carried out.

Pass-or-fail Preventive Maintenance Checklist

Some parts of an asset have a pass or fail state. For some medical equipment their ability to contain gasses is a pass or fail state or a temperature gauge accurately recording the correct temperatures. A Pass-or-fail Medical Equipment Preventive Maintenance Checklist ensures these key components are operational.

How to create a Medical Equipment Preventive Maintenance Checklist

It’s important to make a checklist that works specifically for the type of equipment you service and the industry you service. There may be some considerations you have to make that are unique to your industry but there are some tried and tested methods that are true regardless of the type of assets you service.

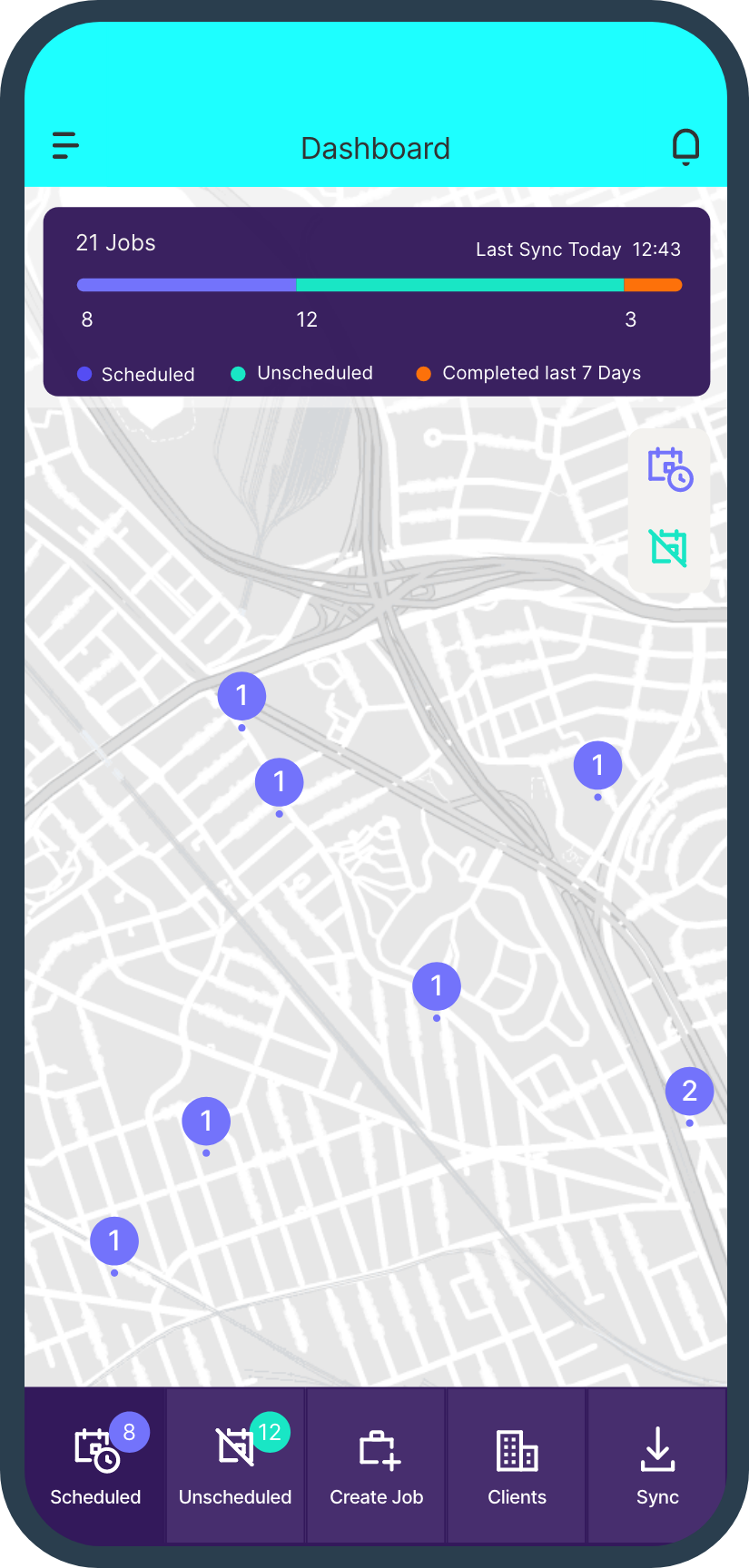

These are fundamentals of a Medical Equipment Preventive Maintenance Checklist and following these stages will ensure your team is safe, the correct checks are made and your client’s assets remain working in peak condition.

1. Safety

Ensure the inspection location is accessible and safe to reach.

2. Environment

Clean away any debris, dirt and ensure any monitors or screens associated with the device can be viewed.

3. Inspect

Carefully review the asset and look for leaks in sections of piping, cracks in the structure and unsafe exposed wiring.

4. Adjust

Tighten or adjust parts that require small adjustments to correctly calibrate the machine or secure it firmly.

5. Replace

If you identify sections or parts of the asset that need replacing due to exceeding the hourly usage cap or they are damaged, have these replaced.

6. Repair

If repairs are needed and can be carried out on site these can happen now you’ve ensured the area is safe to work and anything that only needed small adjustments have been actioned. In some cases a repair will require removing the device and taking it to a service centre. In these instances a replacement asset can be installed where suitable.

7. Report

You may be required to report the results of your Preventive Maintenance to your client. In that instance your report can include details of your repairs and inspections.

8. Reschedule

Continued preventive maintenance means committing to ongoing inspections and maintenance. After you’ve completed your maintenance and reported back to the customer

How to use Field Service Management Software to build Medical Equipment Preventive Maintenance Checklists

A commitment to a Preventive Maintenance programme requires consistency and will create a lot of admin. You’ll have checklists to complete, reports to write and an increased volume of notes from the engineer and technicians.

This information must be collected in a way that’s easily accessible and repeatable. That’s why Field Service businesses are turning to Field Service Management (FSM) Software. The digital forms and the benefits that a single source of shared information you get from FSM Software make it the perfect solution to equipment maintenance data collection.

How to make digital forms

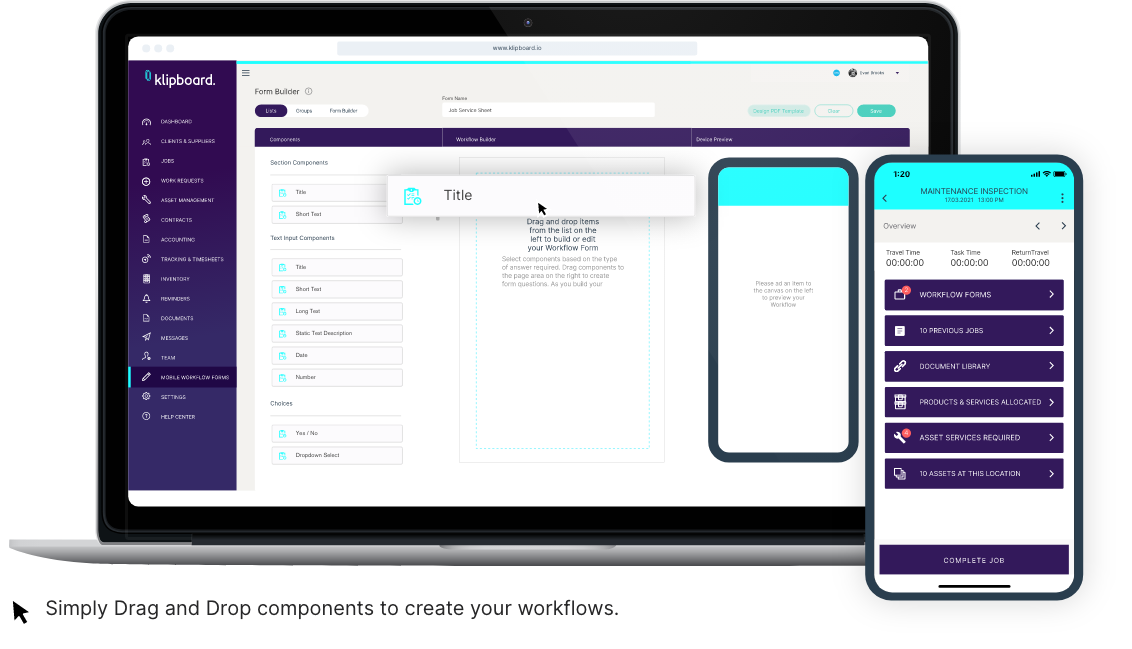

Digital Forms are a great way to collect data from Field Service jobs. Engineers or Technicians can complete their Medical Equipment Preventive Maintenance checklists on their smartphones or tablets, then sync that information back to the office.

Creating these forms requires you to use FSM Software. Whether or not you can build your own forms is dependent on that particular software provider.

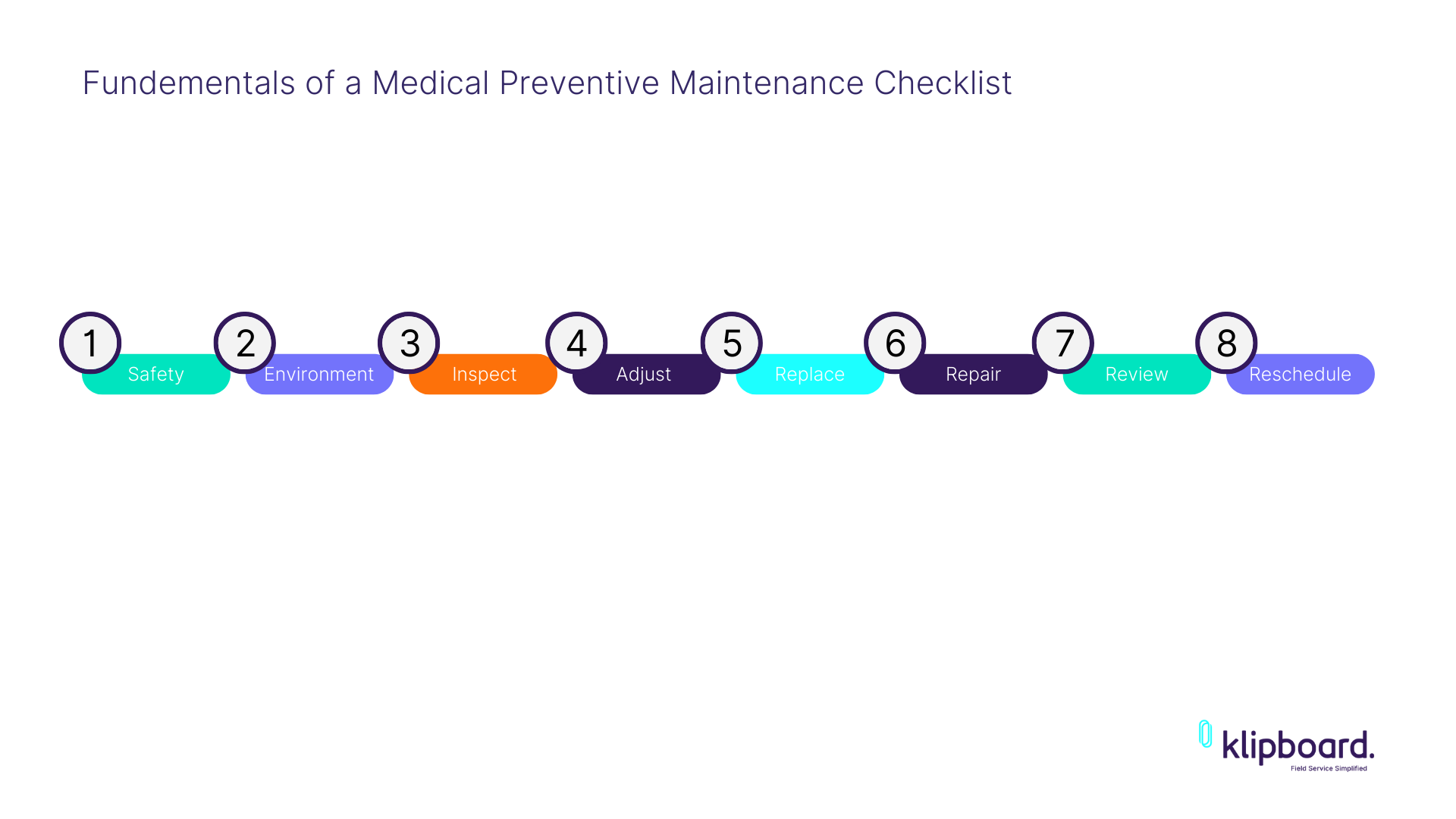

At Klipboard we empower you to build your own with our intuitive and easy to use mobile form builder. You can create as many forms as you need and build them to meet each specific need you have from a client or type of Medical Equipment.

Using Klipboard’s Drag and Drop form builder you can create forms in minutes and share them with your team. Simply pick the components of the form you need such as, Form Title, Type of Job, Description of work and Asset Details.

Then once the form is complete and you’ve saved it, you can start to attach it to relevant maintenance jobs.

Create PDF Reports from your Forms

FSM Software greatly improves how efficiently your team can capture data from the field. It also provides you with a way of taking the details entered into your digital forms and turning them into professional PDF reports.

Our PDF builder works in a similar fashion to the form builder as you are able to drag and drop fields onto a PDF template. These fields will be auto-completed with the details captured on your jobs, allowing you to email a great looking summary of work without having to spend hours typing up your notes.

How Deva Medical benefits from managing their Medical Equipment Maintenance Checklists through Klipboard

Deva Medical carries out preventive maintenance on sophisticated medical equipment. They are responsible for multiple assets, over multiple sites and customers. To meet the challenge of completing all of their scheduled maintenance jobs, they turned to Klipboard.

Owner, Sarah Betteley, needed to ensure her team could access this complex laying of data they gather from their inspections and maintenance jobs. This was very time consuming as they needed to collect the data captured from Medical Equipment Maintenance Checklists, asset service history records and client details. This took far longer than seems necessary so they looked for a way to bring in operational efficiencies.

They brought in Klipboard to help them meet the growing needs of their customers. The demands on the business as it grew meant they could no longer afford to spend so many hours on admin and the cost of adding new hires to the team to manage the admin seemed unwarranted.

“To be able to easily see the work was previously carried out on a piece of equipment is so valuable” – Sarah Betteley, Deva Medical

Klipboard gave them a single place to store all job information and have this available to their whole team. It meant they could easily find what they needed and react quickly when their customers needed them.

Read more: Why Deva Medical uses Klipboard