Medical facilities and clinics have an obligation to ensure their equipment is in peak condition.

Patient welfare and meeting regulatory standards for their medical devices are critical to their operation. However, the services supporting them by carrying out medical equipment maintenance are in dire need of modernisation to keep up with demand.

Businesses that carry out Medical Equipment Maintenance are in huge demand

In the US and EU it is a legal requirement to ensure Medical Devices are correctly serviced and maintained.

The medical industry is highly regulated and facilities need to make sure their medical equipment is serviced regularly to satisfy the requirements set by the U.S Food and Drug Administration (FDA), or equivalent European standards such as the Medical Devices Regulation (MDR).

It’s this need to meet compliance standards by regularly carrying out planned preventative maintenance on medical devices that creates such high demand for servicing businesses.

A rise in awareness of the benefits of planned medical equipment maintenance is feeding demand

The rising awareness of the benefits of preventative medical equipment maintenance, the impact of COVID-19 and the looming threat of future variants of similar viruses has positively impacted the medical market and put a spotlight on patient welfare.

The US is leading the Medical Equipment Maintenance market

The US healthcare system provides the ideal conditions for Medical Equipment Manufactures and Biomedical Equipment Maintenance businesses to offer innovative solutions to their patients and customers.

While the North America region is the largest market for Medical Equipment Maintenance, the fastest growing region is the Asia-Pacific, due to the rapid rate at which countries such as China are building Hospitals and Medical Facilities.

The medical equipment maintenance market is expected to grow by 9% during 2020-2030

Increased demand is creating a huge opportunity for Medical Equipment Servicing businesses to step in and provide this valuable service. It’s estimated that the medical equipment maintenance market will be worth $45.1 billion by 2030.

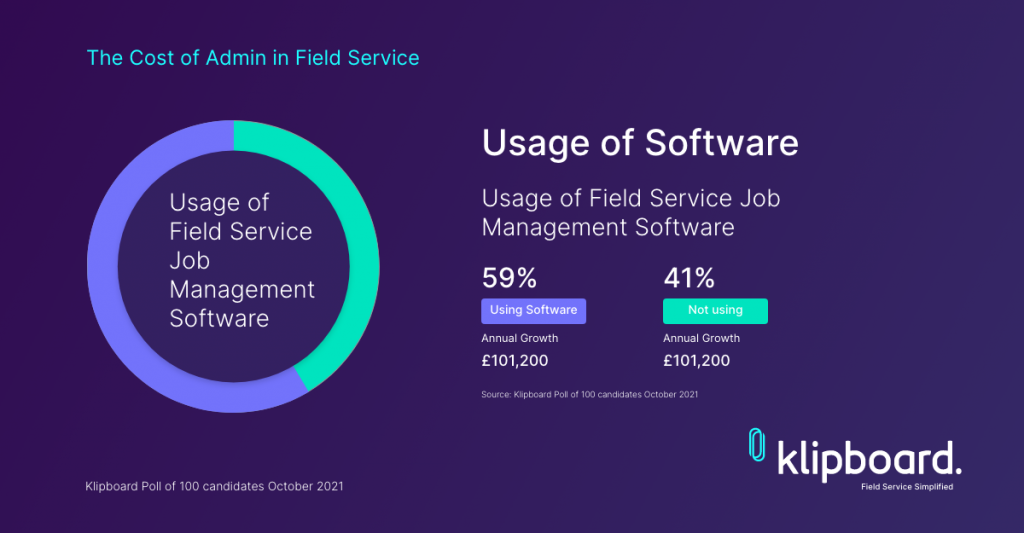

Medical Equipment Maintenance is carried out on cutting edge tech using old fashioned processes

Many of the maintenance companies tasked with ensuring state-of-the-art medical equipment such as microscopes and imaging machines, are still managing their day to day operation in outdated and inefficient processes.

Medical Equipment Maintenance Job Scheduling needs improving

Visibility of what medical equipment needs servicing and communication with the clinics, hospitals and private medical facilities, seem to be the largest concern for Medical Equipment Servicing business owners.

Antiquated ways of scheduling jobs and creating reports are causing bottlenecks for work that needs to be carried out and the shortage of skilled technicians and engineers is only adding to the problem.

Many Medical Equipment servicing businesses still manage their Technicians and Field Engineers using calendars and emails. Apart from the obvious volume of admin this creates for the support team or management, it also leaves the businesses at risk from miscommunication or errors leading to missed jobs.

Without a centralised source gathering information such as service histories for medical equipment is time consuming

A lack of a centralised, single source of information is causing issues for servicing businesses when they need to gather data for an audit.

Service histories on medical equipment, documentation and reports can take hours to pull together and often this is asked for at short notice.

The added pressure to meet the client’s demands creates stress on the medical equipment maintenance teams and creates a poor customer experience if they can’t meet their demands.

Each hour spent looking for these records is one less spent servicing the equipment and ensuring customer satisfaction is maintained.

Using paper-based forms leaves the door open for human error and non-compliance

Some Medical Equipment Servicing businesses still use paper based methods for collecting data in the field and completing tests.

These paper-based forms are rarely updated when there are changes in regulatory testing standards and relies too heavily on the engineer to know the extra checks they need to make.

Failure to ensure the correct procedures have taken place will mean revisiting the customer and could mean the equipment is non-operational for a period of time.

Once the data is collected in the field using paper based forms the information still needs to be entered into their system back in the office which takes additional time.

All of this is avoidable by using more modern approaches to medical servicing procedures in the field.

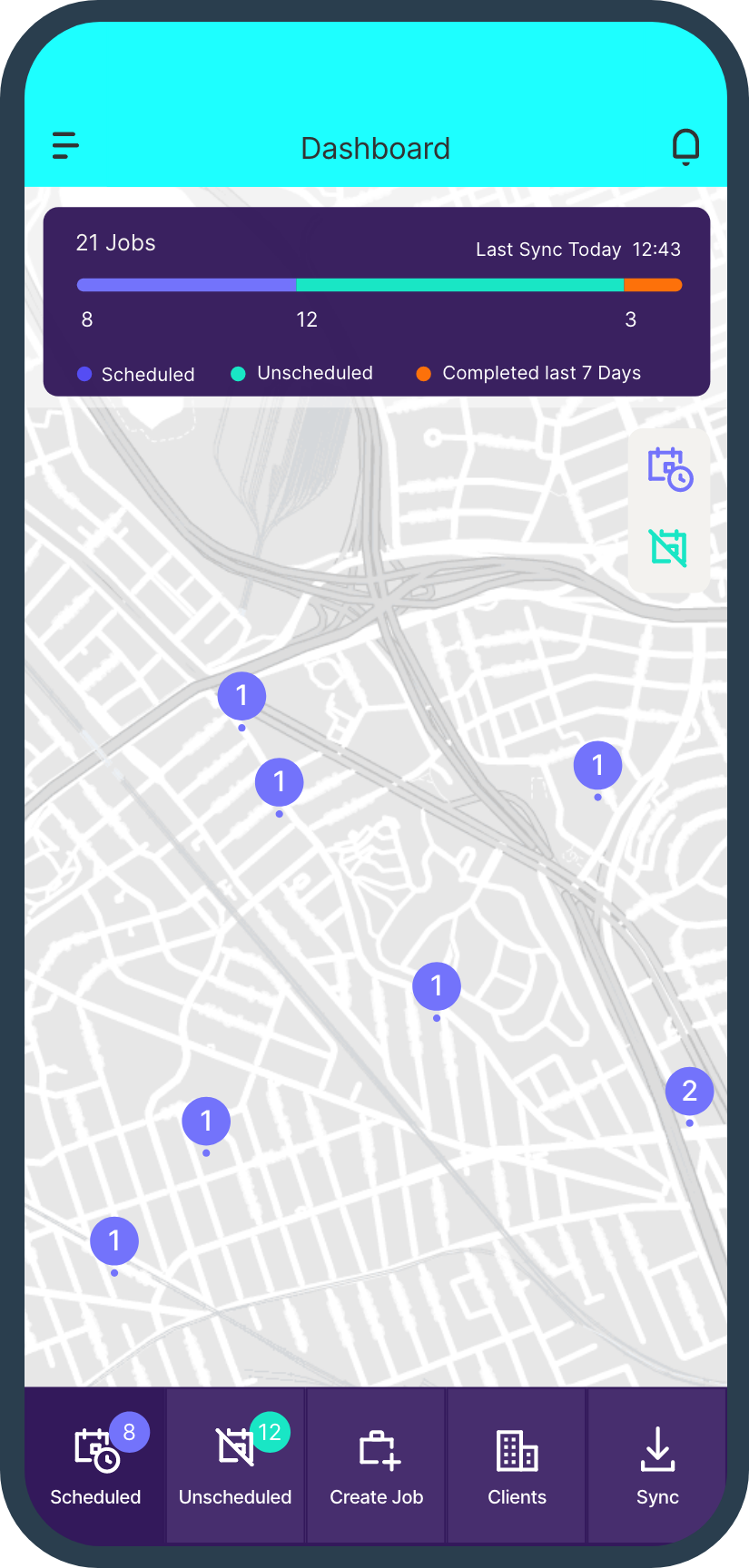

Less than 60% of Field Service businesses use software to manage their jobs

Field Service in general across all industries are still lagging behind when it comes to modernising their business.

Only 59% of Field Service businesses use Field Service Job Management Software to schedule their jobs and complete their work.

Despite offering many solutions to the challenges they face when trying to operate efficiently, many businesses have yet to modernise their operation by adopting this technology.

How Medical Equipment Maintenance businesses are modernising their operation

A growing number of medical equipment maintenance businesses are realising the need to modernise their processes. To keep up with the demands and expectations of their customer how they operate day to day will need to change,

Their customers are expanding the range of equipment they are using and the regulatory standards for each new device means something new to adapt to.

There’s very little bandwidth left for Medical Equipment Maintenance businesses to train their teams and still get held down by the relentless admin that’s created.

Job Management Software for Field Service businesses are providing a simple solution. It’s easy to adopt and can revolutionise how a medical equipment maintenance business operates.

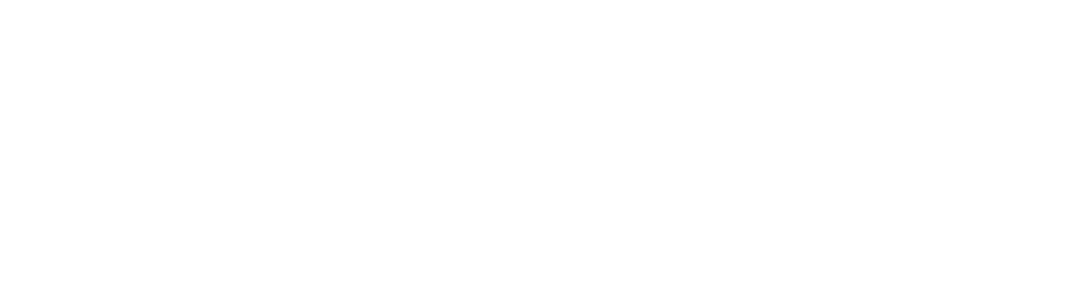

Smart scheduling tools are simplifying job management

Tools such as intuitive drag and drop scheduling are helping medical equipment maintenance businesses organise their workload more efficiently.

They can easily assign technicians and engineers to jobs while achieving complete oversight of the rest of their team.

They can see where there is potential for additional jobs to be added or should an immediate requirement arise, they will be able to quickly inform the customer when that job can take place.

This addresses one of the key challenges for medical equipment maintenance businesses who are often told about a required service at very short notice.

Client records, service histories and an Asset Register all in one place

Prior to using Job Management Software, a medical equipment maintenance business would need to collect the information in preparation for a job or for an upcoming audit by searching through multiple systems.

This is time consuming and often important pieces of information can be lost.

Having an all-in-one platform allows servicing businesses to quickly access what they need and share that information with their client or service teams.

This creates a much more professional approach to client management and will reduce the time it takes to gather the information significantly.

Many Job Management Software platforms are cloud based. That means all the information is held on a server and can be instantly accessed by anyone using the web platform or even a mobile app.

The key benefit with a cloud based job management platform, is enabling teams in the field to quickly access documentation, manuals, guides and client information, without resorting to finding emails or waiting for the information to be sent to them.

Field service teams will know they have the most up to date forms, workflows and documentation when they sync their devices with the software.

Mobile forms and Workflows ensure compliance is achieved

Mobile Forms are the modern equivalent of paper based or triplicate carbon forms of the past.

Engineers and Technicians arrive on a job with everything they need on their smartphone app. All the forms they are required to complete for services are available for them by using Job Management Software.

By including mandatory fields on forms that are updated once and sent out to all teams, it allows medical equipment servicing businesses to standardise their tests and inspections.

When every check is complete and the engineer is satisfied they can gather their client signature sign off straight onto their device. This is then instantly uploaded to the Job Management Software platform, helping to streamline the whole process.

How Klipboard helped Medical Equipment Maintenance provider Land Sea & Sky modernise their business

A challenge that business owners face is where to start looking for a software partner.

There’s plenty of big names and well established software providers in the market, but which one is the right Job Management Software for medical equipment maintenance businesses?

What Land Sea & Sky needed from their Job Management Software partner

Chris Hysinger, owner of Land Sea & Sky (formerly Texas Nautical) is one of the largest medical servicing businesses in the state of Texas, US.

When he bought the company he knew immediately that he needed to modernise some of their processes. In particular he needed to address the concerns he had around job scheduling and using paper based forms for completing tests.

“Klipboard has revolutionized our ability to track each asset service” – Chris Hysinger, Land Sea & Sky

Finding medical equipment service records takes seconds rather than hours

Land Sea & Sky use Klipboard so they are able to quickly retrieve details of customer medical devices and service records instantly.

Previously this could have taken a significant amount of time for Chris and his team to search multiple platforms to gather the information they need.

Land Sea & Sky can be more proactive with their scheduling of medical device servicing jobs

Automated service reminders help Land Sea & Sky notify their clients way ahead of time of an upcoming service.

They are able to make room in their schedule and their client is able to accommodate a medical device being unavailable while the maintenance is being carried out.

These Automated Communications with their customers allow them to be more proactive and Klipboard makes them quick and easy to set up.

Here’s Chris explaining the benefits of using Job Management Software for Medical Equipment Maintenance

You can read more on how Land Sea & Sky has adopted Medical Equipment Maintenance job management software by clicking here.