If you’re on a quest to enhance your business’s inventory management processes, your search ends here with this comprehensive guide to inventory management. This guide will lead you through various inventory management systems, essential objectives, the advantages of an efficient system, techniques, strategies, and more.

By grasping the significance of inventory management and implementing the right system tailored to your business, you can elevate customer satisfaction, reduce costs, and optimize inventory forecasting. Additionally, you’ll gain insights into cloud-based solutions and best practices that empower you to maximize efficiency when tackling inventory management challenges. Before we dive in, let’s clarify: What is inventory management?

Understanding Inventory Management

If you find yourself puzzled about what inventory management entails and why inventory management strategies matter, you’re not alone! Perhaps your field service business is just starting to handle inventory, or maybe managing inventory was straightforward when it was stored in the back of your truck. However, now, the importance of tracking inventory has grown.

Inventory management is a crucial process for any business. Neglecting to monitor what enters and exits your stockpile not only affects your business’s financial health but also jeopardizes customer satisfaction. Customers may face shortages and decide against repeat business due to delays in completing work. Moreover, your field staff can’t operate efficiently if the materials they need aren’t readily available.

The primary goal of inventory management is to ensure the right materials are on hand in the right quantities at the right time, facilitating on-time completion of work while minimizing costs. The choice of inventory management systems depends on your business’s size. Smaller companies may opt for simpler solutions like manual stock level tracking, while larger enterprises may benefit from sophisticated software systems capable of automating tasks such as demand forecasting or maintaining optimal stock levels.

Regardless of the system employed, certain key objectives should guide effective inventory management, including ensuring accurate order fulfillment, monitoring stock levels, avoiding shortages and excesses, reducing storage and handling costs, and enhancing customer satisfaction.

Exploring Types of Inventory Management

Inventory management techniques vary from one business to another. They entail meticulous monitoring of stock levels to ensure seamless business operations and prevent customer disappointment. To aid in inventory optimization, several common inventory management types are practiced:

- Cycle Counting: This method divides your business’s entire inventory into smaller segments, allowing you to count a portion at a time instead of conducting a full physical count regularly. It enables the quick identification of issues for timely resolution.

- ABC Analysis: Categorizing items into three groups (A: high demand/high cost; B: medium demand/medium cost; C: low demand/low cost) helps prioritize products requiring attention.

- Just-in-Time (JIT): This approach minimizes waste by delivering only the necessary materials precisely when they are needed, avoiding excess reserves. To manage efficiently, JIT is often combined with cycle counting or ABC analysis.

- Perpetual Inventory: This system maintains real-time tracking of current stock levels through automatic updates whenever items are added or removed, ensuring accuracy without reliance on physical stock counts.

Choosing the appropriate inventory management techniques for your business depends on factors such as budget, business size, and your ultimate goals. Additionally, cloud-based solutions offer convenient data accessibility without the maintenance costs associated with traditional systems.

Key Objectives of Inventory Management

Barcode scanner scanning a cardboard boxAccomplishing efficient inventory management not only sustains high customer satisfaction levels but also trims costs linked to storage and handling. It provides visibility into your supply chain, allowing the early identification of potential problem areas. Forecasting techniques further enable planning for high-demand seasonal jobs and leveraging supplier discounts for bulk orders.

Moreover, cloud-based solutions are increasingly favored due to their scalability, cost-saving potential, and ability to seamlessly integrate with existing systems. These solutions offer a central repository of information accessible to multiple stakeholders. They provide rapid access to inventory details from anywhere through mobile accessibility options.

When properly executed and managed, effective inventory management facilitates profit maximization by enabling informed decisions on bulk or just-in-time material ordering. Consequently, your customers continue to enjoy positive interactions with your business, free from delays or material shortages that could hinder work completion.

Benefits of Efficient Inventory Management

When adopting a new system or process within your business, it’s crucial to understand the benefits it brings. The same holds true for efficient inventory management.

First and foremost, it ensures customer satisfaction by maintaining optimal stock levels and preventing stockouts. This enables customers to schedule and complete work promptly. Additionally, an organized system grants better control over inventory costs through accurate future forecasting and cost savings related to storage and handling fees.

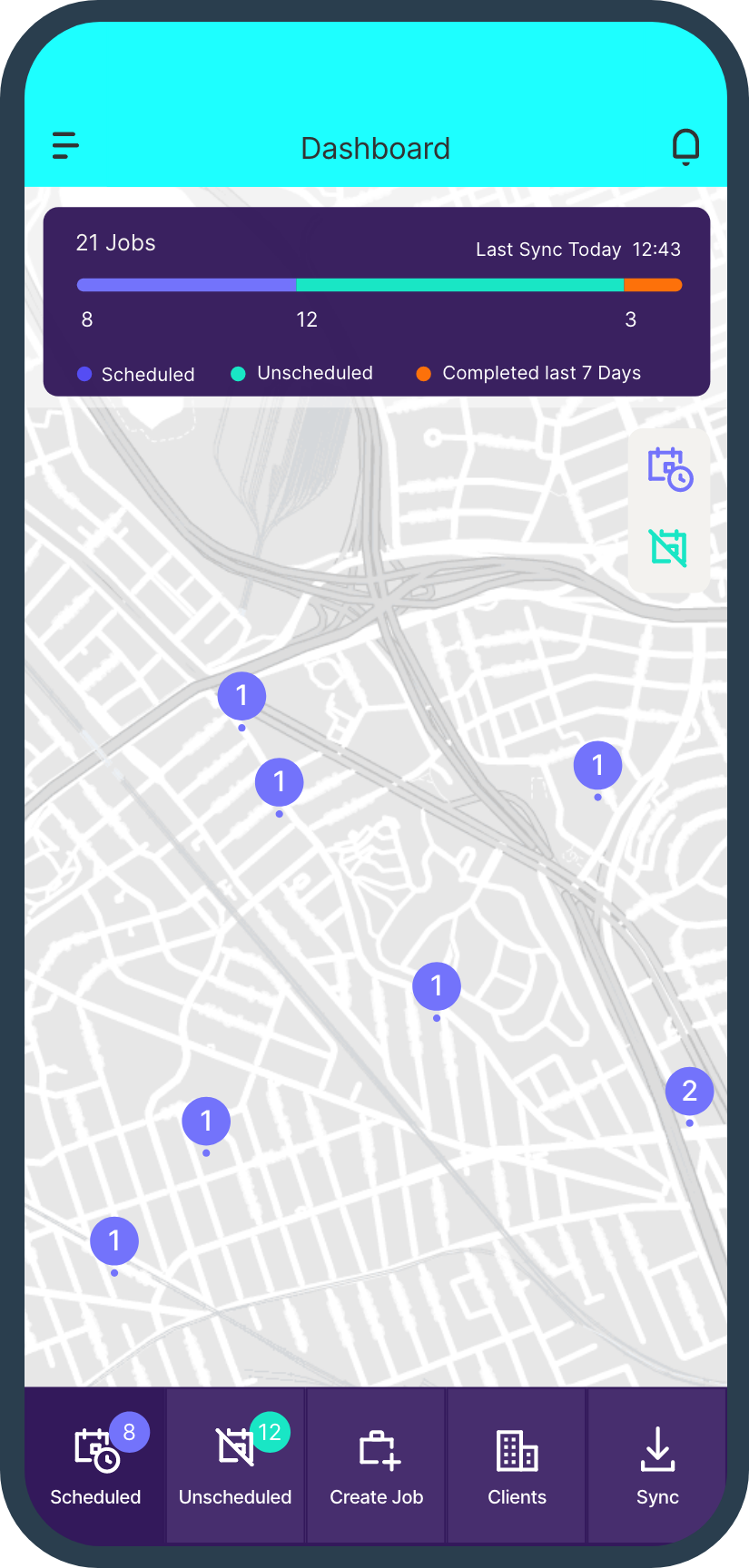

Cloud-based solutions offer real-time tracking capabilities, enabling remote monitoring of your inventory from any location worldwide via mobile devices. This enhanced visibility aids field staff in preparing their vans with the right materials for each job, ensuring seamless operations.

How often has incorrect stock placement become an issue? Field staff must ensure their vans are fully equipped with the necessary materials for the day’s tasks. Without an efficient inventory management system, materials can go missing, leading to delays and staff frantically searching for items. Transparency is key, and a cloud-based solution achieves it by providing digital access to inventory reports and availability checks from anywhere.

In summary, an efficient inventory management system is essential for maintaining a positive customer experience, enhancing transparency, and reducing operational expenses related to material storage. By utilizing the right mix of technologies, processes, and tools, you can ensure customer satisfaction while effectively managing costs.

Breaking Down Common Inventory Management Techniques

Finger pressing a button labeled “Inventory Techniques”Inventory management encompasses various techniques that allow you to maximize efficiency and minimize costs. Here are a few examples:

- Just-in-Time (JIT): This method minimizes lead times by ordering only what is necessary when needed, reducing storage costs. JIT is often used to maintain minimal stock levels before replenishment is necessary.

- Economic Order Quantity (EOQ): EOQ calculates the optimal order quantity to minimize ordering costs while anticipating future needs based on demand.

- Reorder Point: This method triggers alerts when inventory reaches a predetermined level, signaling the need to reorder before stocks run critically low.

- Perpetual Inventory: Tracking material and stock changes over time, this method records transactions much like sales or purchases, ensuring real-time accuracy.

Understanding these inventory management techniques empowers you to streamline operations, maintain high customer satisfaction, and reduce costs effectively. Implementing a suitable system helps you stay organized, increase profits, and manage resources efficiently.

Cloud-Based Inventory Management Systems

When pondering the question “What is inventory management?” it’s challenging to envision a response without involving electronic or digital solutions. Automated systems streamline operations, reduce the effort and time required for inventory management, and provide insights into job trends. They also enable the prediction of future material requirements and optimize procurement processes.

Adopting a cloud-based system for inventory management offers real-time visibility into material inflow and outflow. It empowers field staff to manage their inventory, and it allows you to check various storage locations from anywhere. This technology saves time associated with manual inventory management processes, a significant boon for businesses.

With a cloud-based solution, the initial setup is smooth and hassle-free. You can import supplier catalogues, group catalogue items, and assign materials to jobs with a few clicks, streamlining your workflow. After the setup, you can update your inventory as needed and establish alerts for low stock levels.

Storing inventory data in the cloud offers security benefits, as data is securely backed up remotely, reducing the risk of data loss. Field staff can access this information with a stable internet connection, facilitating their daily tasks and enhancing customer service.

The scalability of cloud-based inventory management systems is particularly advantageous for growing businesses. You can adjust your catalog as needed without physical limitations, ensuring your inventory management scales with your business.

Whether your goal is inventory forecasting, cost reduction, or increased efficiency, cloud-based inventory management systems offer numerous benefits. Leveraging these solutions saves time and money while ensuring customer satisfaction and operational transparency.

Considerations When Selecting a Cloud-Based Inventory Management Solution

Choosing the right cloud-based inventory management solution requires careful evaluation. The ideal system should align with your unique needs, industry, and processes while seamlessly integrating with other software systems. Consider the following key aspects when weighing your options:

Features and Customization

Ensure the system offers all the necessary features for effective inventory management, and inquire about customization options to tailor the system to your specific requirements.

Scalability

Assess how well the system adapts as your business expands. A flexible solution should accommodate the addition of new products or services, market expansion, or increased customer demand.

Security Measures

Prioritize systems with robust security protocols to protect data from unauthorized access or modifications. Customizable security settings should grant the right individuals access to the appropriate information.

Cost

Evaluate all costs, including initial setup fees and ongoing maintenance expenses, to determine the system’s affordability.

Integration Capabilities

Confirm that the chosen solution seamlessly integrates with other software systems, such as accounting software (e.g., Sage or Xero), to streamline business processes and avoid duplicated tasks.

In conclusion, efficient inventory management is pivotal to your business’s success. It ensures customer satisfaction, cost optimization, and operational efficiency. By selecting the right inventory management system, implementing best practices, and embracing cloud-based solutions, you can enjoy the benefits of streamlined operations and enhanced customer service.