Effective Asset Maintenance Plannings a crucial aspect of ensuring the smooth and reliable operation of any type of customer asset. Proper maintenance planning involves the strategic coordination of resources, schedules, and tasks to optimise equipment performance, minimise downtime, and ultimately, enhance overall productivity. In this blog, we will delve into the key concepts and benefits of maintenance planning, as well as explore some practical strategies for successful implementation.

Understanding Maintenance Planning

Maintenance planning is the process of defining, scheduling, and organising maintenance activities to ensure that equipment and assets are regularly inspected, serviced, and repaired to prevent failures and breakdowns. It is a proactive approach that aims to prevent unplanned downtime, which can lead to significant production losses and increased maintenance costs.

The Key Components of Maintenance Planning

- Asset Inventory and Condition Assessment: The first step in maintenance planning is to create an inventory of all assets and equipment within the facility. Conducting a thorough condition assessment helps determine the current state of each asset, identifying potential issues and estimating their remaining useful life.

- Criticality Analysis: Not all assets have the same impact on operations. Criticality analysis helps prioritize assets based on their significance to production, safety, and overall functionality. High-priority assets require more frequent and meticulous maintenance planning.

- Maintenance Strategies: Depending on asset criticality, age, and complexity, different maintenance strategies may be employed. These can include preventive maintenance (scheduled routine tasks), predictive maintenance (using data and analytics to forecast failures), and corrective maintenance (addressing unexpected breakdowns).

- Resource Allocation: Efficient maintenance planning involves optimizing the allocation of resources such as labor, spare parts, and equipment. Balancing these resources ensures that the right personnel with the appropriate skills are available, and that spare parts are in stock when needed.

- Scheduling and Work Orders: Maintenance activities should be scheduled to minimize disruptions to operations. Work orders are used to document and communicate the details of each task, ensuring that maintenance personnel have clear instructions.

- Data Management and Analysis: Maintenance planning relies on data, including equipment histories, performance metrics, and sensor data. Utilizing data management and analysis tools helps in making informed decisions, identifying patterns, and fine-tuning maintenance strategies.

Benefits of Maintenance Planning

- Reduced Downtime: Planned maintenance helps identify potential issues before they cause breakdowns, minimizing unplanned downtime and its associated costs.

- Increased Equipment Reliability: Regular maintenance enhances equipment reliability, extending its lifespan and reducing the likelihood of major failures.

- Improved Safety: Well-maintained equipment is less likely to malfunction, reducing the risk of accidents and injuries in the workplace.

- Enhanced Efficiency: Properly maintained assets operate more efficiently, leading to reduced energy consumption and improved overall process efficiency.

- Cost Savings: Although maintenance planning requires an initial investment, it is more cost-effective than reactive maintenance in the long run.

- Compliance and Regulations: Some industries have strict regulations regarding equipment maintenance. Proper planning ensures compliance with these standards.

Implementing Effective Maintenance Planning

- Collecting and Analyzing Data: Gather historical maintenance data and analyze equipment performance to identify patterns and make data-driven decisions.

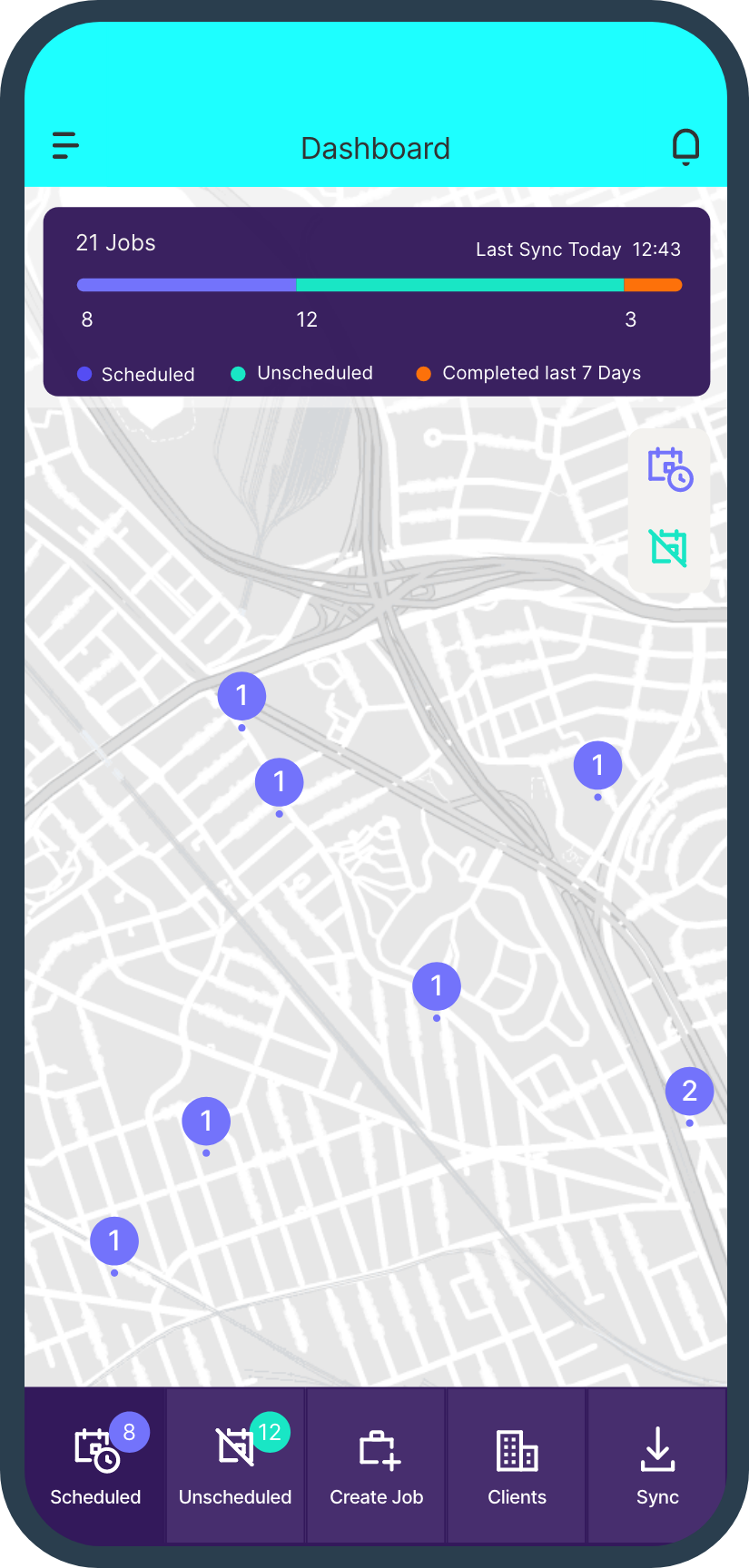

- Investing in Technology: Utilize computerized maintenance management systems (CMMS) and predictive maintenance tools to streamline planning processes and optimize resource allocation.

- Training and Skill Development: Ensure that maintenance personnel are well-trained and up-to-date with the latest maintenance techniques and technologies.

- Collaboration and Communication: Foster effective communication between maintenance, operations, and management teams to align goals and objectives.

- Continuous Improvement: Regularly review and refine maintenance strategies based on feedback, data analysis, and changing operational needs.

Conclusion

Maintenance planning is a vital aspect of modern industrial operations. By effectively managing maintenance tasks, organizations can ensure the reliability and longevity of their equipment, reduce downtime, and ultimately improve productivity and profitability. Embracing a proactive approach to maintenance planning empowers businesses to stay ahead of potential issues, capitalize on opportunities for efficiency gains, and create a safer working environment for their employees. As technology continues to advance, maintenance planning will become even more sophisticated, enabling industries to achieve higher levels of performance and sustainability.

Discover the future of Facilities Management Software.