We delve into the dynamic world of asset maintenance – a vital facet of any thriving field service business.

In an era where technological advancements and industry demands are ever-evolving, the efficient management of assets has become a cornerstone for sustained success. Whether you’re a seasoned field service professional seeking the latest insights or a newcomer navigating the intricacies of maintenance strategies for your customer, our article is your compass in this landscape of preventive practices, digital transformation, and operational resilience.

We will unravel the complexities of asset maintenance, exploring innovative solutions, industry best practices, and the transition from reactive firefighting to proactive excellence for your customer. Together, let’s embark on a journey toward optimising asset performance, minimising downtime, and unlocking the full potential of your business operations.

In the ever-evolving landscape of field service businesses and technology, the concept of asset maintenance has taken on new significance

What was once considered a routine, behind-the-scenes function has now become a pivotal player in ensuring operational efficiency, reducing downtime, and safeguarding valuable investments on behalf of your customers.

The Evolution of Asset Maintenance: From Reactive to Proactive

Traditionally, asset maintenance operated on a reactive model, where maintenance activities were triggered by your customer in response to equipment failures or breakdowns. Today, businesses are increasingly shifting towards a proactive approach, aiming to identify and address issues before they disrupt operations. This evolution is fueled by the integration of advanced technologies such as predictive analytics, Internet of Things (IoT), and machine learning.

Preventive Maintenance in the Digital Age

One of the pillars of modern asset maintenance is preventive maintenance. Instead of waiting for assets to fail, field service businesses are now leveraging data-driven insights to schedule regular maintenance tasks, inspections, and repairs for their customers. This not only minimizes the risk of unexpected downtime but also extends the lifespan of assets, optimizing their performance over time.

The Role of Technology: Asset Maintenance 4.0

In today’s context, Asset Maintenance 4.0 is synonymous with the integration of cutting-edge technologies into maintenance practices. Artificial intelligence (AI) is employed for predictive maintenance, analyzing historical data to forecast potential failures. IoT sensors provide real-time monitoring, enabling condition-based maintenance and immediate response to emerging issues. Digital twins, virtual replicas of physical assets, offer a simulated environment for testing maintenance strategies before implementation.

Centralised Management with Asset Maintenance Software

The advent of Asset Maintenance Management Software has revolutionised how organisations handle maintenance processes. These software solutions provide centralized platforms for managing work orders, tracking maintenance activities, and analyzing performance data. The result is enhanced organisation, streamlined workflows, and improved collaboration among maintenance teams.

Sustainability and Environmental Considerations

In the contemporary business landscape, sustainability is a key driver of decision-making. Asset maintenance now goes beyond ensuring operational efficiency; it encompasses environmentally conscious practices. Organizations are incorporating green maintenance strategies, considering the environmental impact of maintenance activities and adopting measures to minimize their carbon footprint.

Challenges and Opportunities in Today’s Asset Maintenance Landscape

While the integration of advanced technologies brings numerous benefits, it also presents challenges such as data security concerns, the need for upskilling the workforce, and the initial investment in new technologies. However, these challenges come hand in hand with opportunities to create more resilient, efficient, and sustainable maintenance practices.

What features should you consider when choosing Asset Maintenance Management Software?

Selecting the right Asset Maintenance Management Software is crucial for field service organisations to ensure efficient management of customer assets, reduce downtime, and extend the lifespan of equipment. Here are key factors to consider when evaluating options:

1. User-Friendly Interface

The software should have an intuitive and user-friendly interface to facilitate easy adoption by maintenance teams.

2. Asset Tracking and Management

Comprehensive asset tracking capabilities to monitor the entire lifecycle of assets, from acquisition to disposal.

Support for categorising assets based on type, location, criticality, and other relevant factors.

3. Preventive Maintenance Scheduling

Ability to create and schedule preventive maintenance tasks to prevent equipment breakdowns and extend asset lifespan.

Automated reminders and notifications for upcoming maintenance activities.

4. Work Order Management

Efficient creation, assignment, and tracking of work orders.

Real-time updates on work order status and progress.

5. Inventory Management

Integration with inventory management systems to track spare parts and consumables.

Automated reordering capabilities to maintain optimal stock levels.

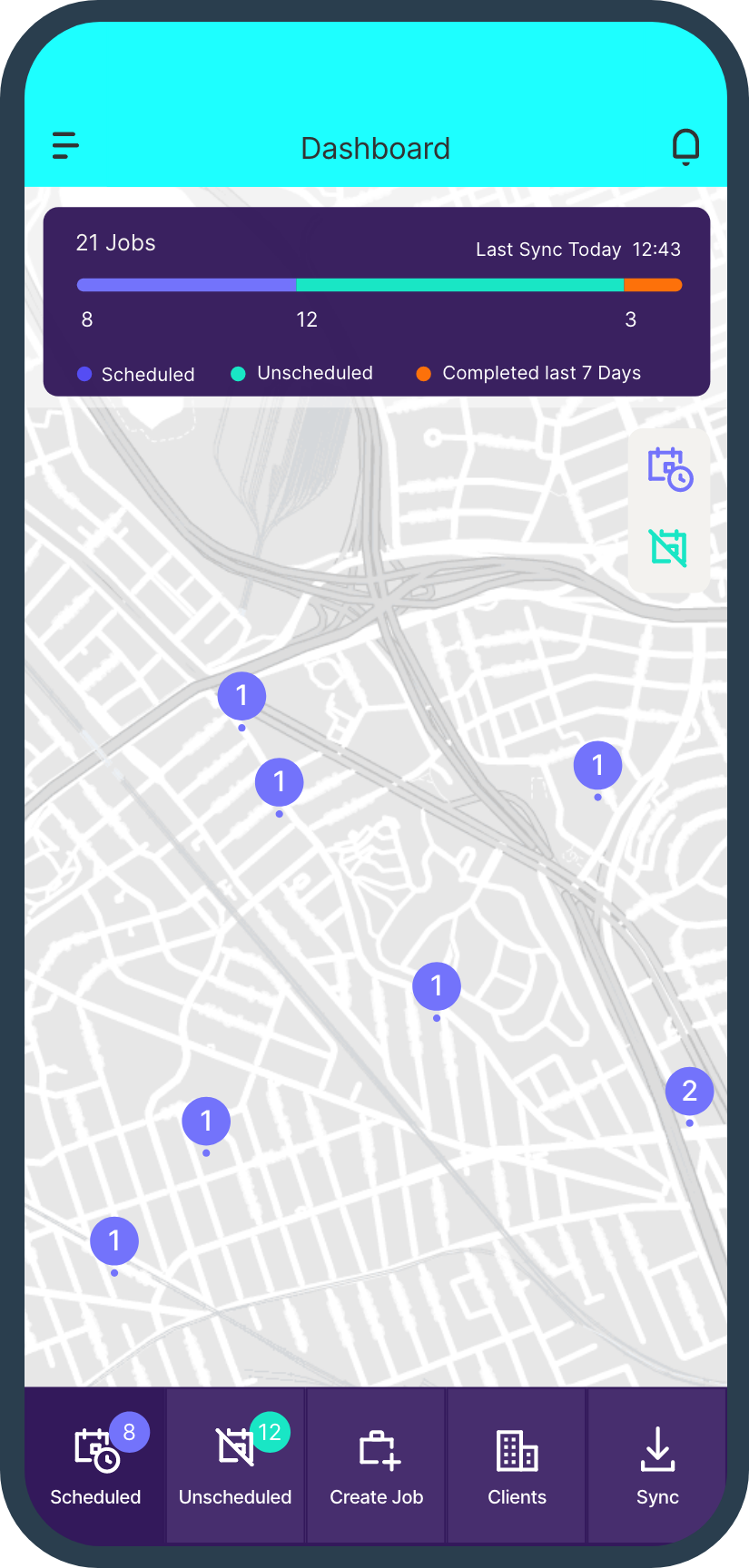

6. Mobile Accessibility

Support for mobile devices to enable field technicians to access and update information on the go.

Mobile apps for both iOS and Android platforms.

7. Reporting and Analytics

Robust reporting tools to generate insights into asset performance, maintenance costs, and overall equipment effectiveness.

Customisable dashboards for quick visualisation of key metrics.

8. Compliance and Regulations

Compliance with industry regulations and standards.

Audit trail capabilities for tracking changes and ensuring accountability.

9. Scalability

Ability to scale the system to accommodate the growing number of assets and users.

10. Data Security

Robust security features to protect sensitive asset and maintenance data.

Role-based access controls to restrict access based on user roles.

11. Vendor Support and Training

Adequate vendor support and training resources to assist with implementation and ongoing usage.

Regular software updates and maintenance.

12. Cost Effectiveness

Transparent pricing structure with no hidden costs.

Consideration of total cost of ownership (TCO) over the long term.

13. User Feedback and Reviews

Consider user reviews and feedback to gauge the experiences of other organizations using the software.

By carefully evaluating these factors, organisations can select an Asset Maintenance Management Software that aligns with their specific needs and helps optimise asset performance and reliability.

Have you encountered asset maintenance KPIs? Wondering about the abbreviation? KPI stands for key performance indicators. These are measurable metrics or data points utilised by businesses to assess and monitor their advancement toward particular goals and objectives. KPIs aid in efficient performance management and enable data-driven decision-making. Some fundamental attributes of asset maintenance KPIs encompass:

1. Asset Uptime

Percentage of time that assets are operational and available for use.

2. Mean Time Between Failures (MTBF)

Average time between asset failures, indicating the reliability of equipment.

3. Mean Time to Repair (MTTR)

Average time taken to repair assets after a failure, measuring maintenance efficiency.

4. Preventive Maintenance Compliance

Percentage of scheduled preventive maintenance tasks completed on time.

5. Overall Equipment Effectiveness (OEE)

A comprehensive metric that considers availability, performance, and quality to assess the overall efficiency of equipment.

6. Work Order Completion Time

Average time taken to complete work orders, reflecting the responsiveness of the maintenance team.

7. Maintenance Cost per Unit

Total maintenance costs divided by the number of units produced or assets maintained.

8. Asset Health Index

A composite measure assessing the overall health and condition of assets.

9. Inventory Turnover

How quickly spare parts and inventory are used or replaced, indicating efficiency in managing stock levels.

10. Energy Consumption per Asset

Measurement of energy consumed by each asset, helping to identify energy-efficient or inefficient equipment.

11. Compliance with Regulatory Standards

Ensuring that asset maintenance practices align with industry regulations and standards.

12. Mean Time to Failure (MTTF)

Similar to MTBF, but focused on measuring the average time until an asset fails.

13. Percentage of Reactive vs. Proactive Maintenance

Balancing reactive maintenance (responding to unplanned failures) and proactive maintenance (scheduled preventive actions).

14. Technician Productivity

Tracking the number of maintenance tasks completed per technician within a specified period.

15. Asset Criticality

Identifying and prioritizing assets based on their criticality to business operations.

16. Spare Parts Availability

Ensuring that necessary spare parts are readily available when needed for maintenance activities.

17. Safety Incidents Related to Maintenance

Monitoring and reducing the number of safety incidents during maintenance tasks.

18. Customer Satisfaction

Gathering feedback from internal or external customers to assess their satisfaction with asset performance.

These KPIs provide insights into various aspects of asset maintenance performance, and field service organisations may choose and customise them based on their specific goals and industry requirements. It’s important to regularly review and adapt KPIs to align with evolving business needs and industry trends.

Welcoming the Era of Modern Asset Maintenance

Staying ahead in asset maintenance requires a holistic approach that combines technology, data-driven decision-making, and a skilled workforce. By embracing predictive maintenance, leveraging technology, and prioritising preventive strategies, field service organisations can not only optimise their asset management but also gain a competitive edge in their industries. Regular reviews, employee training, and a commitment to continuous improvement are essential elements in the journey to staying ahead in the dynamic landscape of asset maintenance.