Field Service Simplified.

Job Management Software built for your world.

Streamline operations, make smarter decisions and supercharge your team with an all-in-one field service platform.

No Obligation

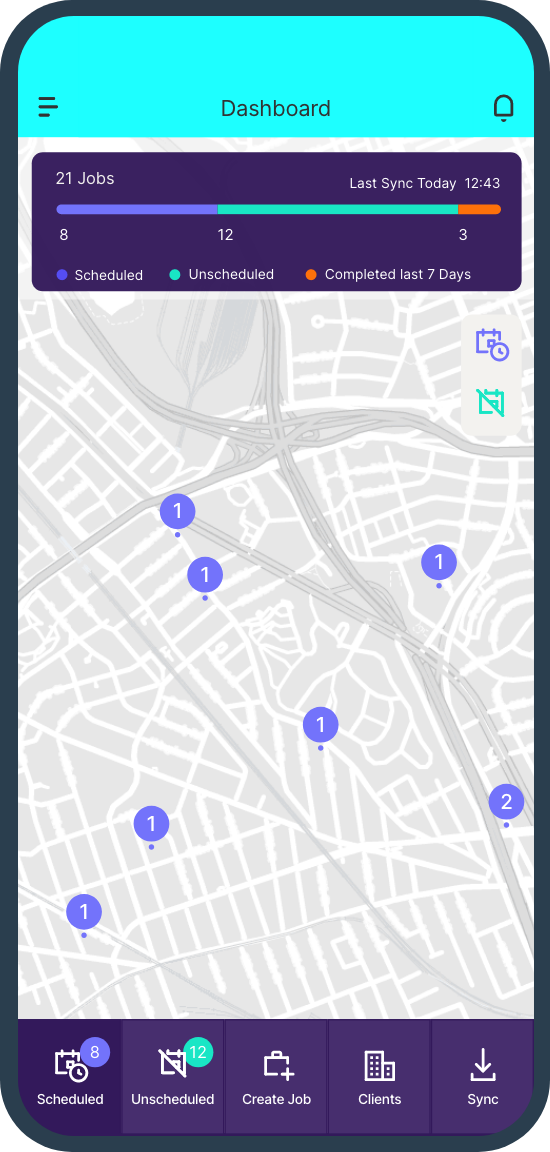

Real-time visibility, intelligent features and all the information for your team in one place. Klipboard is your all-in-one platform for job management, scheduling, planned maintenance, invoicing, quoting, automated communications, reporting and more.

Our field service management software is feature rich and supports a wide range of businesses who perform service jobs, project and maintenance management.

Start FREE TrialSuccessfully run your business with a single software platform. With features for office and field, Klipboard's cloud-based Job and Field Service Management software gives you everything you need to manage operations and grow your business.

| Keep track of your leads and convert more opportunities to jobs by tracking your performance. | |

| Create professional quotes for your customers to approve online instantly. | |

| Make sure customers are happy after every appointment with automated follow up emails and reviews. | |

| Never miss a work request, get real time notifications when a customer submits a work request booking. Instantly review and one click to convert to a quote or job. |

| Drag. Drop. Done. Our intelligent schedule optimisation, streamlines the process for dispatching jobs to your team. | |

| Know how your business is performing, track all activity on a job and gain insight on progress and financial performance. | |

| No more customer spreadsheets, quickly create, update and manage your customer’s records intuitively through our CRM. | |

| Never miss a Customer’s Asset Service with our automated customer asset service reminders ensuring your customers are notified when their assets are due servicing. | |

| Our iOS & Android mobile apps, gives your field team everything they need to complete jobs whilst ensuring industry best practices are followed. |

| Once a job is complete, speed up your payment process by automatically notifying your client of invoices due payment. | |

| No more needless data re-entry, with a single click, seamlessly convert job costs into invoice line items. Track and manage your business finances with ease. | |

| Our QuickBooks and Xero integrations are hassle free - connect your account and you can save time by seamlessly syncing your field service finances. |

| Automate those repetitive office admin tasks with our range of job management features and you’ll get 25% + of your day back. | |

| Each feature of Klipboard is built with you in mind. Focus on what matters most, your customers. Time gained through using our smart features can be used to grow your business. |

| It is a competitive market and being the cheapest option is not always the winning strategy. Customers are willing to pay more for convenience and ease of doing business with you. | |

| With Klipboard you can easily offer online work request bookings, automated job booking confirmations via email and SMS, a Client Portal, plus much more! |

Take control of your business with flexible software that empowers you to manage it like a true leader. Klipboard is fast to setup and easy to use - it is designed to adapt to your team, specific workflows, existing services, and scales with you as your business grows. Whether your focus is on service jobs, asset maintenance, residential or commercial work, Klipboard is built to cater to all field service workflows, making it a reliable choice for job management software.

For many field service businesses, Klipboard makes field service management a simple and effortless process that enhances their working day. Our teams serve our customers across the world and we process millions of jobs each year through our job management software for small businesses to large enterprises.