Your client has called you on a Friday to tell you their medical equipment needs servicing and it’s due next week.

This is a scenario you’ve likely experienced before and if you haven’t then it’s likely you’ve experienced something similar in your medical equipment maintenance business.

It’s easy to presume this happens because your client doesn’t consider your workload. However, this happens because of a breakdown in communication and poor visibility of service due dates on both sides, you and the client.

Demand for Medical Equipment Maintenance is heating up

The Medical Equipment Maintenance market is expected to grow to $45.1 billion by 2030. It’s already growing at an incredible rate and demand for the services of medical servicing companies will continue to rise.

With that demand comes complications. It means juggling the challenges of job scheduling, recruiting new team members and improving communication between you and your clients.

Without a plan in place to modernise your business and empower your team to complete the jobs you’ll struggle to keep up with the work you have let alone add new customers.

Common job scheduling challenges faced by Medical Equipment Maintenance businesses

Managing the Planned Preventative Maintenance schedules for medical devices comes with plenty of challenges. Whether you’re servicing the private sector, large scale hospitals or smaller healthcare clinic, you’re facing similar challenges.

Ensuring Medical Devices meet compliance

Almost all medical devices need regular servicing to ensure they are safe for use and perform at standards that ensure patient welfare is maintained. That’s a huge responsibility for Hospitals, clinics and health care centres so they have service partners tasked with carrying out planned preventative maintenance (PPM) schedules that need to be documented.

To manage these schedules effectively, a medical equipment maintenance business needs to be very organised, they need to have excellent visibility of their schedule and be flexible enough to adjust it if their customer calls them out for an unexpected repair or service.

To meet compliance and the regulatory standards they need to prove the correct checks have taken place. Forms and Workflows are used by the Field Engineer, often on a tablet, iPad or smartphone to ensure each required check has been made and the equipment is operating as expected.

Part availability

Having Field Engineers available is only half the challenge, they still need to have the resources available to carry out repairs when required.

In recent years Global Supply Chain issues have made getting parts or replacement medical devices challenging. To navigate around that particular challenge Medical Equipment Maintenance businesses need greater visibility of their inventory.

Maintaining a good First Time Fix Rate

Downtime of assets for most customers can prove costly. For medical facilities it can seriously affect their patients welfare so they rely on their service partners to ensure they fix faults at the first time of asking.

A major challenge for Medical Equipment Maintenance businesses is keeping up a positive First Time Fix Rate (FTFR). A good FTFR for most servicing businesses is around 80%.

When a Medical Equipment Maintenance businesses is able to sustain a good FTFR it can help build trust with the client and ensures their field teams are able to complete more jobs.

Manage unexpected call outs

Medical Devices need to be reliable and fully operational when called upon. The patients welfare is at risk should equipment be unavailable due to faults or non-compliance.

Medical equipment Maintenance businesses need to be able to react when called out for an emergency repair or service. Excellent trust and rapport is built when service partners are able to react to a call out and come up with a speedy resolution.

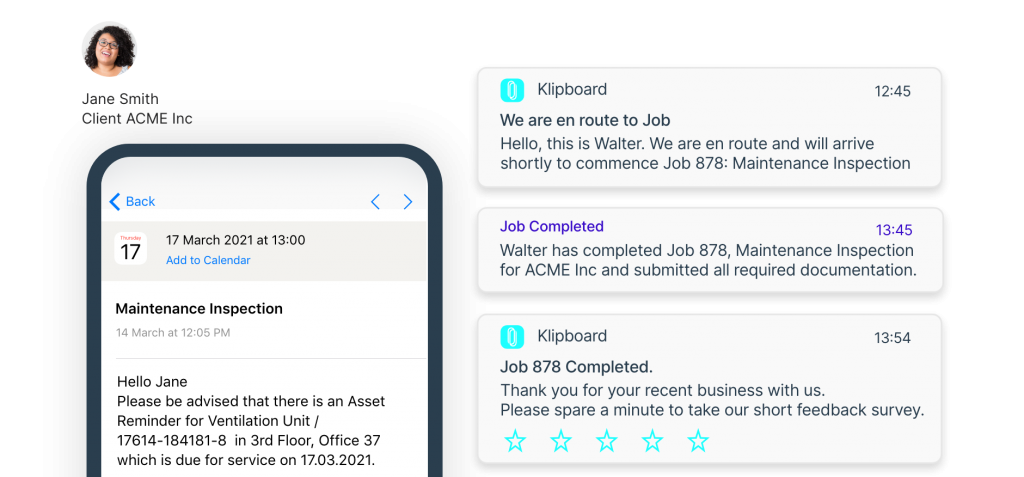

To effectively manage call outs Medical Device servicing businesses need to handle the in-bound request promptly and professionally, they need complete visibility of their team’s schedule and have real time notifications to confirm bookings.

Many Medical Equipment Maintenance business use Job Management Software to send Job Management Software to assign jobs to their Field Team and inform the client when they should arrive on site.

How to stop getting caught out by unexpected Medical Equipment Maintenance jobs

In most instances your client won’t be aware of when their medical devices need their next service or inspection to meet compliance.

As team members change on your client’s side and new equipment is introduced it makes keeping on top of service dates very challenging.

There are steps you can take to step up your servicing game and ensure you can meet your clients expectations and even allow room in your schedule to add more jobs.

Start with Job Management Software for Medical Equipment Maintenance

To schedule medical servicing jobs like a pro you need the right software.

You’ll need Job Management Software that perfectly aligns with how you run your business. You’ll need to consider how your typical jobs are managed and use the software to streamline how you work.

- Do you have to manage an Asset Register?

- Are the Assets located over several different locations?

- How often do you need to service them?

- Do you have a single point of content with the client?

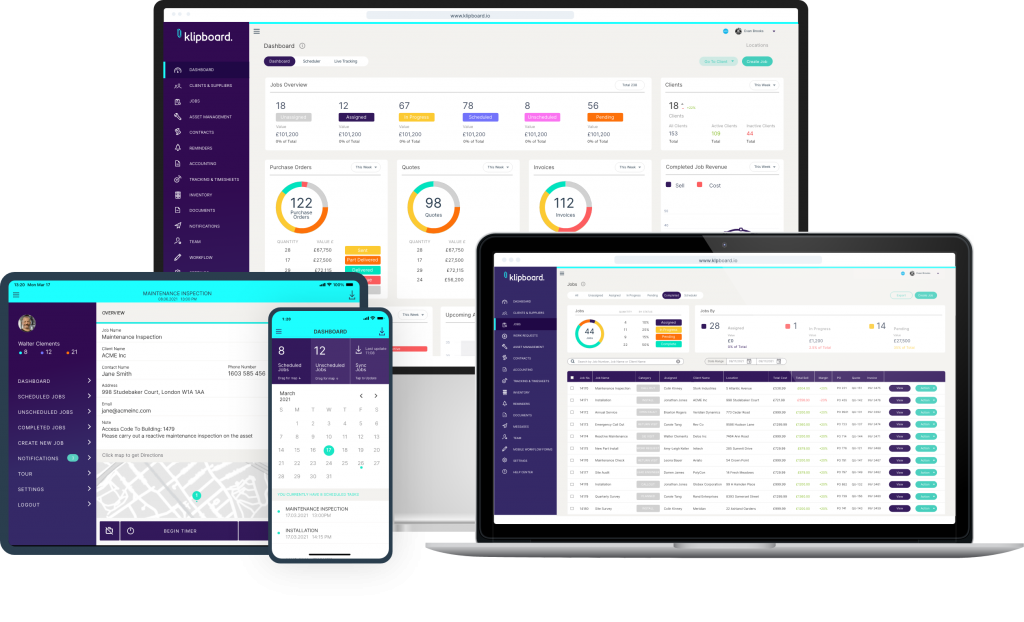

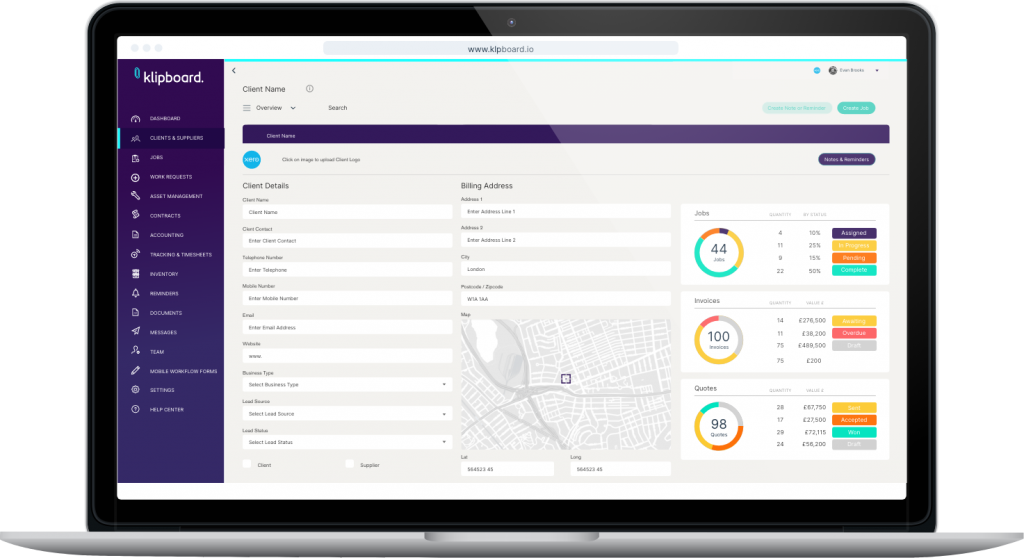

To efficiently manage a Medical Device Servicing team using Job Management Software you’ll need Asset Management Tools, Automated Service Reminders and CRM features.

Sure, there’s likely to be dozens of other neat features you could benefit from but by starting at the beginning and focus on those basic features you’ll initially have everything you need.

Benefits of using Asset Management Tools for Medical Equipment Maintenance

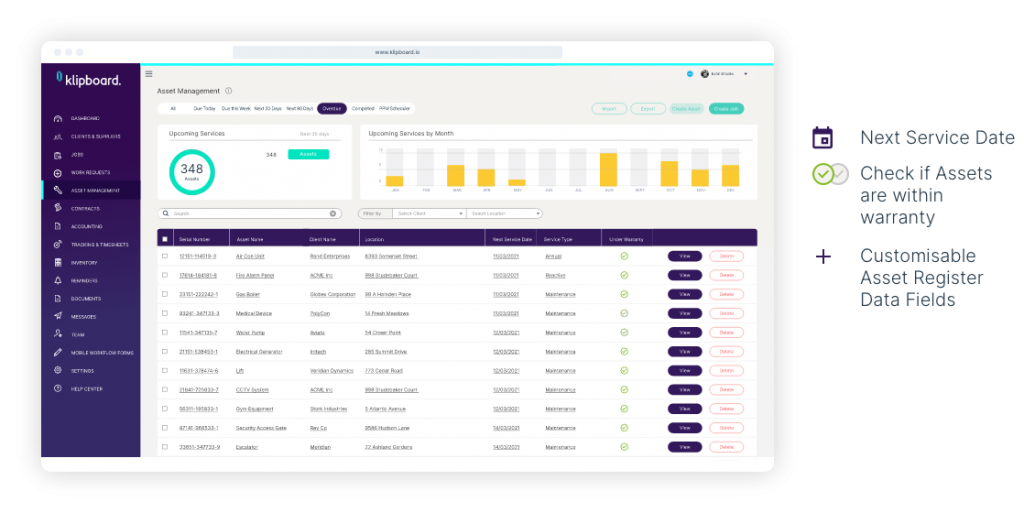

The most important feature to look for in your Job Management Software are the Asset Management Tools.

When you get a demo of the software this is likely to be where you’ll need to ask the most questions and ensure it aligns with how you want to work.

You’ll need to be able to add individual assets, assign them to locations and add details such as serial numbers, asset tags, model numbers and servicing schedules.

That way you can track the service history and see what work has been completed and what’s outstanding.

Automated Service Reminders allow Medical Equipment Maintenance businesses to be more proactive

Before using Job Management Software, a lot of medical device servicing businesses would struggle to know when the dates were for their client’s next service.

When you have multiple assets, across multiple locations, that’s a lot of dates to keep on top of. Often service teams will be caught out at the last minute when a medical engineer calls the servicing business to say they have equipment that needs servicing.

By setting up Automated Service Reminders, you can proactively contact the client and let me know when they have an asset due a service. This gives you more time to plan around the job and the client knows you’ve got their interests and their assets covered.

Any unexpected downtime of medical devices could be costly for the facility and affect the quality of care their patients receive.

Job Management Software stores everything you need in one place

Maintaining your job details, service history, asset register and client information on different systems just slows you down.

If your client contacts you to request servicing information for an audit it can catch you off guard and could take hours without a centralised system.

You can create a more professional experience by storing everything you need in one and accessing it instantly with Job Management Software.

Ensure the software you choose is cloud based. That means when your team in the field requires information they can pull that down from a single, regularly updated source.

3 ways Klipboard helps you maximise the productivity of your team

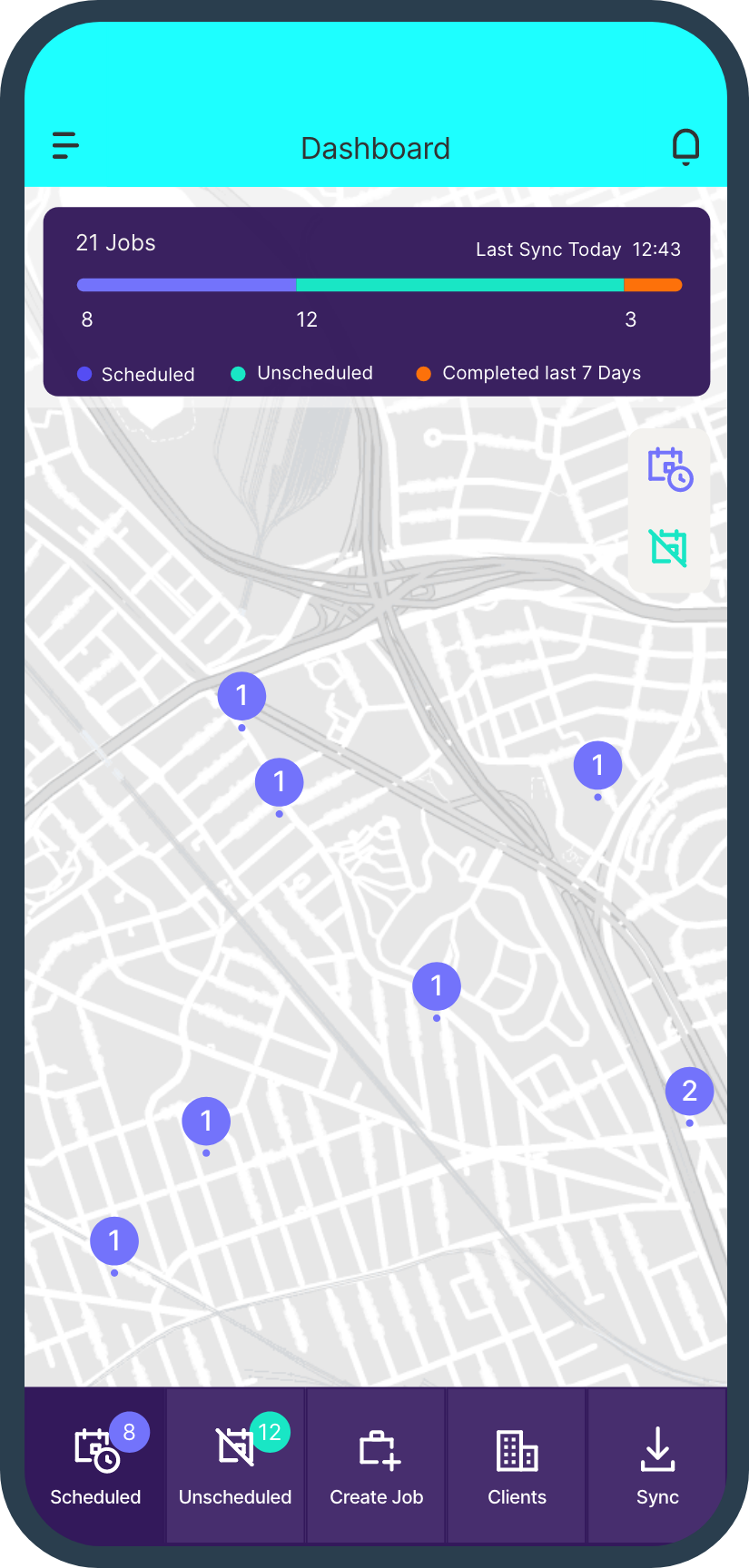

Klipboard Job Management Software for Medical Equipment Maintenance allows you and your team to have instant access to all the information they need and automatically notify your client when a service is due.

Trusted by Medical Device servicing professionals. It’s the all-in-one job management software that will modernise your operation and simplify your job scheduling.

Here’s 3 reasons why Klipboard is the perfect choice for medical device job management:

1. Simple to set up automated service reminders help you notify your customer that their assets require servicing and give you plenty of time to prepare your schedule.

2. Asset Management Tools for medical equipment, your customer can’t afford for their business critical equipment to miss a service. Their assets need to meet compliance and you’ll help them achieve this by giving you greater visibility of service dates.

3. Bespoke schedules for customers help ensure no matter what particular service schedules your customer needs you’re flexible enough to handle each PPM schedule.

Start a Free Trial Today