Reactive maintenance, also known as breakdown or corrective maintenance, is a common approach in various industries, where maintenance activities are carried out in response to equipment or machinery failures. In such scenarios, reactive maintenance software can be a game-changer. This software streamlines the management of unexpected breakdowns and offers numerous advantages that can enhance your maintenance operations. In this blog, we’ll explore five key benefits of using reactive maintenance software.

1. Improved Equipment Reliability

Reactive maintenance software helps improve equipment reliability by minimizing unplanned downtime. When equipment or machinery fails, the software provides a streamlined process for identifying the issue, assigning tasks, and tracking progress. Maintenance teams can respond quickly to resolve the problem, reducing the time equipment remains non-operational. This swift response not only improves equipment reliability but also minimizes production losses and potential damage to the machinery.

2. Cost Savings

Effective cost management is crucial for any business, and reactive maintenance software can help you control and reduce maintenance-related expenses. By implementing a proactive approach to handling breakdowns, you can avoid unnecessary costs associated with emergency repairs and the potential ripple effect of equipment failures on other systems. Additionally, the software enables you to better allocate resources and schedule maintenance tasks, optimizing the use of labor and materials.

3. Enhanced Safety

Safety is a top priority in maintenance operations, and reactive maintenance software contributes to a safer working environment. It allows maintenance teams to quickly identify and address safety-related issues that could arise from equipment breakdowns. The software provides a structured workflow for assessing risks and implementing safety measures, reducing the likelihood of accidents or incidents caused by unexpected equipment failures.

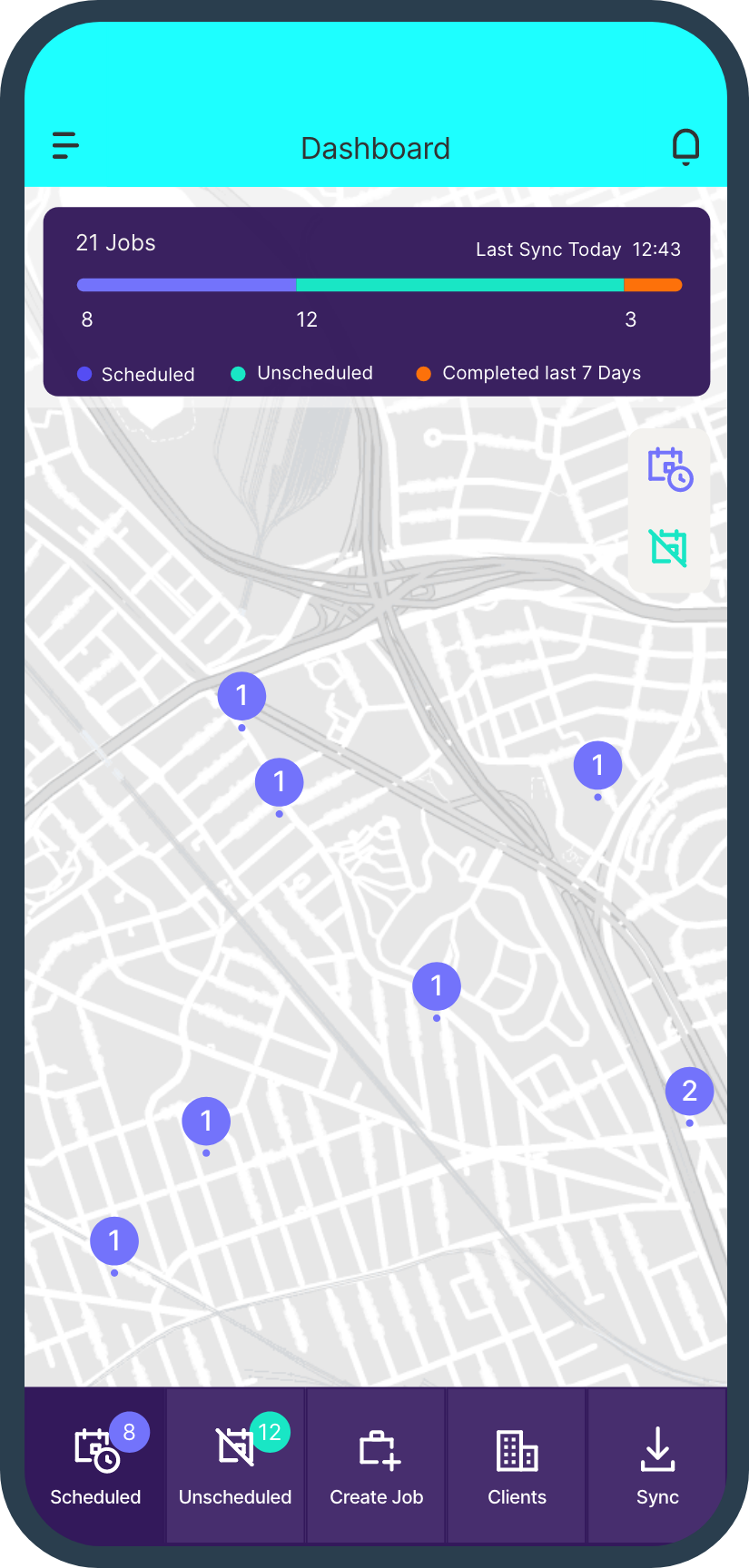

4. Efficient Work Order Management

Managing work orders efficiently is critical for maintaining smooth operations in a reactive maintenance environment. Reactive maintenance software simplifies work order creation, assignment, and tracking. Maintenance teams can access and update work orders from their mobile devices, ensuring that everyone is on the same page and that work is completed in a timely manner. This streamlining of work order management increases productivity and minimizes administrative overhead.

5. Data-Driven Decision-Making

Data is a valuable asset in any maintenance operation, and reactive maintenance software provides the tools for effective data collection and analysis. By recording information about equipment failures, repair times, costs, and other relevant metrics, the software enables you to make informed decisions. You can identify recurring issues, assess the effectiveness of maintenance strategies, and make data-driven improvements to your maintenance processes. This data-driven approach helps your maintenance team become more proactive in preventing future breakdowns.

Reactive maintenance software offers a range of advantages that can enhance the efficiency, cost-effectiveness, and safety of your maintenance operations. By improving equipment reliability, reducing costs, enhancing safety measures, streamlining work order management, and enabling data-driven decision-making, this software provides valuable support for addressing unexpected equipment failures.

It’s a powerful tool for maintenance professionals seeking to minimize downtime, optimise resources, and maintain a safe and efficient working environment. Consider implementing reactive maintenance software to transform your reactive maintenance strategy into a proactive and data-informed process.

Learn more on how Klipboard can help you with reactive maintenance job software here